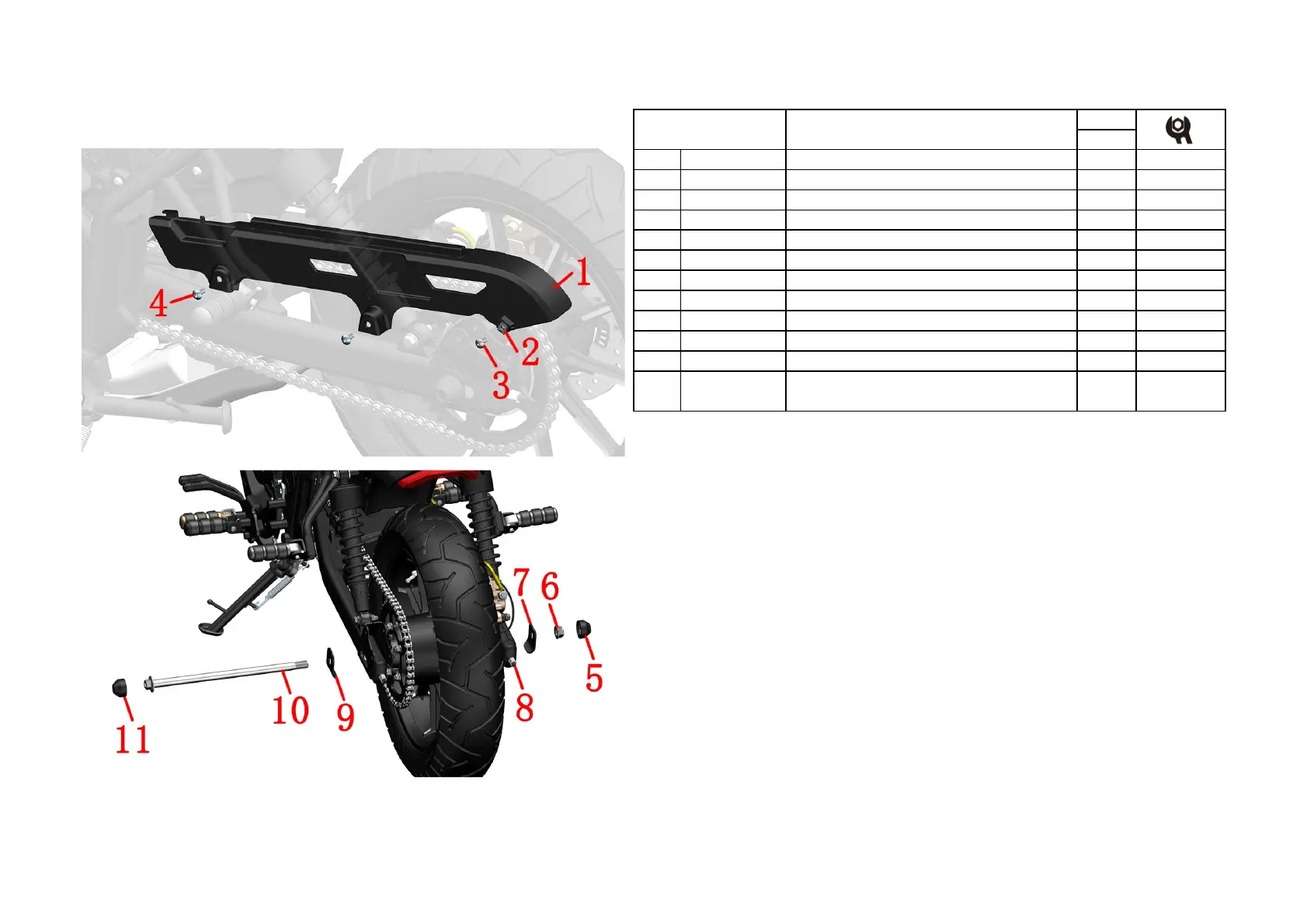

4-REAR WHELL COMPONENT 19

CHK

ADJ

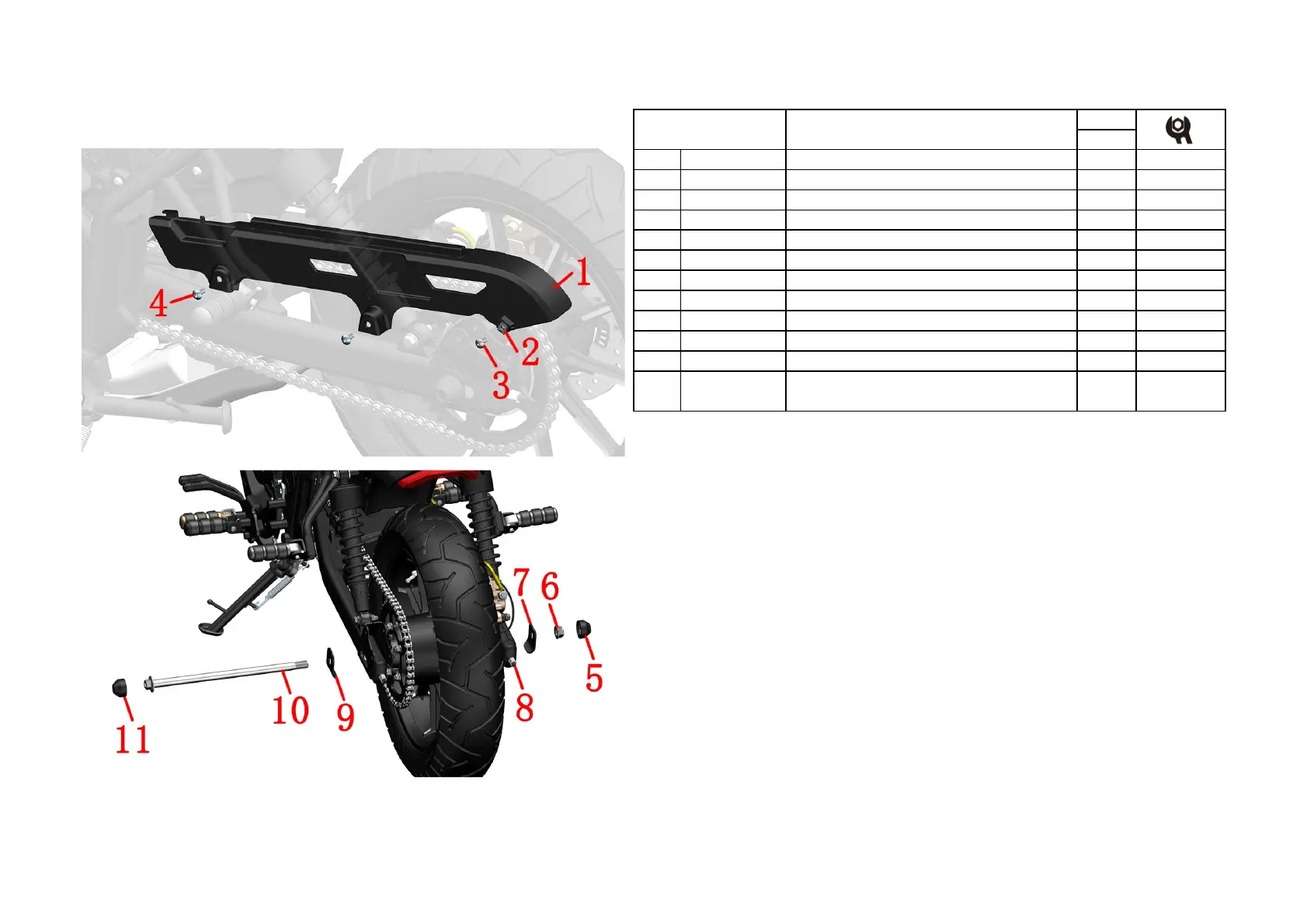

NO. PART NO.

1 4046502-039000 KD200-C chain cover assembly (MES) 1

2 1251300-063093 Plywood M6×11×15(color Zinc) 1

3 1251100-101000 Non-standard bolt M6×12 (304 stainless steel) 1

4 1251100-328000 Hexagon socket head screw M6×14+8.5×3 SUS302 2

5 1246500-016000 KD200-C rear wheel shaft protection rubber sleeve 1

6 1250305-029000 GB6187.1M16×1.5 (Dacromet) 1 80N.m

7 1276500-007000 KD200-C right chain adjuster scaleplate 1

8 Chain adjuster 2

9 1276500-006000 KD200-C left chain adjuster scaleplate 1

10 1096500-004000 KD200-C rear wheel axle (φ17×342) 1

Fig.3 REAR WHELL

COMPONENT

Rear wheel component 1

●Chain box

To prevent damage to the chain box when removing the rear wheel assembly, remove it first. Remove the

chain box assembly from the vehicle by removing the 1 bolt ⑶ and 2 screws⑷ with a 4# hex. Remove the

plywood⑵.

●Rear wheel assembly

Remove the protection rubber sleeve⑹ and⑾. Loosen the nuts of the chain adjusters on both sides first with

a 13# spanner. Secure the head of the rear wheel axle⑽ with a 19# socket on the left side and remove the nut

⑹ with a 21# socket on the right side. Remove the right chain adjuster scaleplate⑺.

Tie the rear disc brake caliper to the rear flat fork with a tie or rope. Push the rear wheel assembly toward

the front of the motorcycle to the end and remove the chain from the chain disc. Tap the rear wheel axle⑽

with a rubber mallet after holding the rear wheel assembly, and remove the right side chain adjuster⑻, the

rear tyre and rim assembly, and the left side chain adjuster⑻in turn.

CAUTION:

●Use suitable tool to support the motorcycle. Avoid accidents caused by falling motorcycle. Single person

manipulation is prohibited.All the standard parts need to reach standard torque while reassembling.

●Using iron hammer to punch rear wheel axle, disc brake clamp assembly is prohibitd.

●While disassembling the rear wheel assemble, avoid the rear disc brake clamp to be lifted higher than the

disc brake oil cup. If not, air will get into the tubes and cause softness or failure on braking system. As disc

brake tubes request extreamly high vaccum degree. Make sure manipulator has maintenance ability before

disassembling the disc brake assembly.

●Check the chain regularly. Increase the frequency of adjustment of the chain according to the driving

conditions. Keep the tightness of chain to be in a suitable range. Too loose chain have possibility to separate

from sprocket or damage the engine. Too tight chain can be worn out quickly.

1246500-021021 1

KD200-C rear wheel shaft head protection rubber

sleeve

11

Loading...

Loading...