Structure and function

2-10 3HDA000057A8519-001 Torch cleaner TC 2013

Assembly instructions

2.3.3 Replacement parts

The replacement parts include:

• Milling cutter (can be ordered individually)

• Replacement spacer plate for the clamping V-block (can be ordered individually)

• Release agent tank (1 litre silicone-free weld spatter release agent)

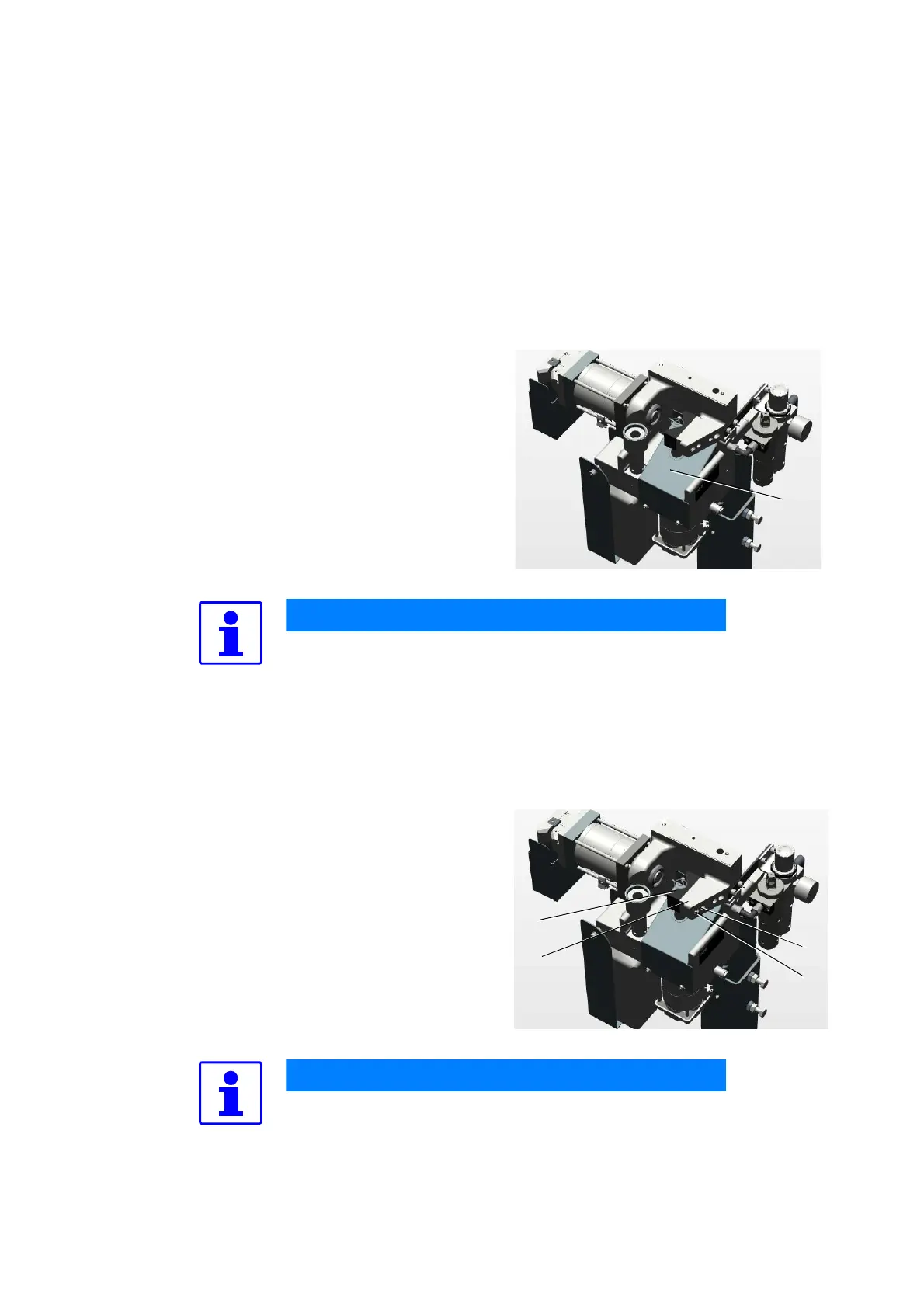

2.3.3.1 Replacing milling cutter

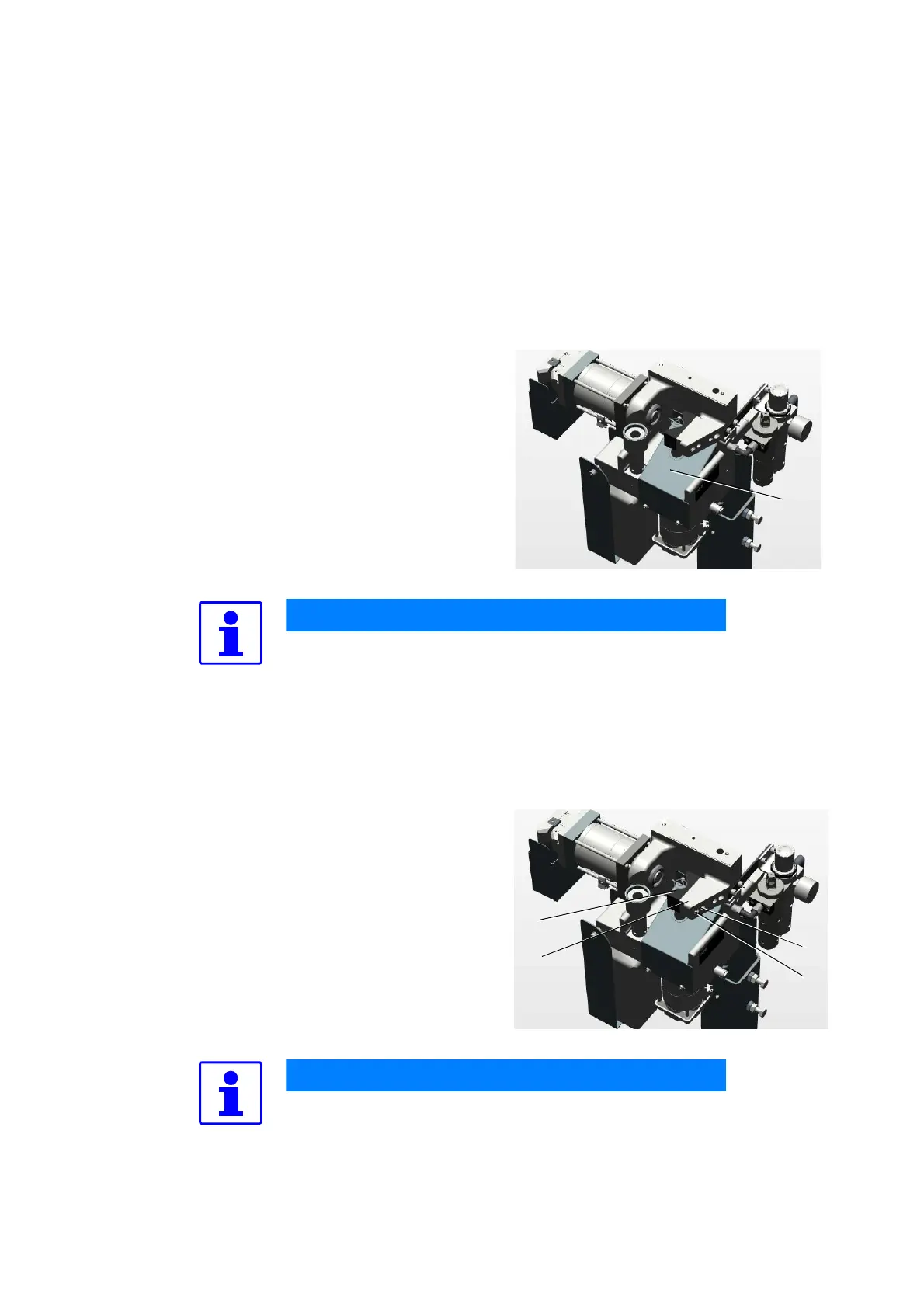

2.3.3.2 Replacing spacer plate

1. Remove protective cover (1).

2. On the milling cutter detach threaded pin M

5x6 and pull off milling cutter.

3. Put on new milling cutter and tighten with

threaded pin M 5x6.

4. Re-attach the protective cover (1) after

replacing the milling cutter.

At the factory the motor shaft is drilled approx. 1 mm

deep through the core hole in assembly of the first mill-

ing cutter in order to safely rule out axial migration of

the milling cutter.

1. The clamping V-block is screwed on with 2

cheese-head screws and pegged. Detach

screws (1) and pins (2).

2. Take off clamping V-block (3) and spacer

plate (4).

3. Select new spacer plate (see Table 2-1) and

screw back on clamping V-block and peg.

The center misalignment of the torch nozzle must then

be corrected in the robot program.

Loading...

Loading...