Assembly and disassembly

Torch cleaner TC 2013 3HDA000057A8519-001 2-13

Assembly instructions

Air quality

The compressed air must comply with „class 4“ or better in accordance with to ISO 8573-1:2010.

Operating pressure

The operating pressure for the TC 2013 must be at least 5 bar and must not exceed 10 bar. It acts

in the same way for all air consumers on the unit.

2.4.4 Setting

2.4.4.1 Setting of milling cutter

Cleaning time and milling cutter feed are directly related. If the milling cutter feed is at its maxi-

mum, the cleaning time should be programmed one second longer. Complete cleaning is

achieved in a shorter time.

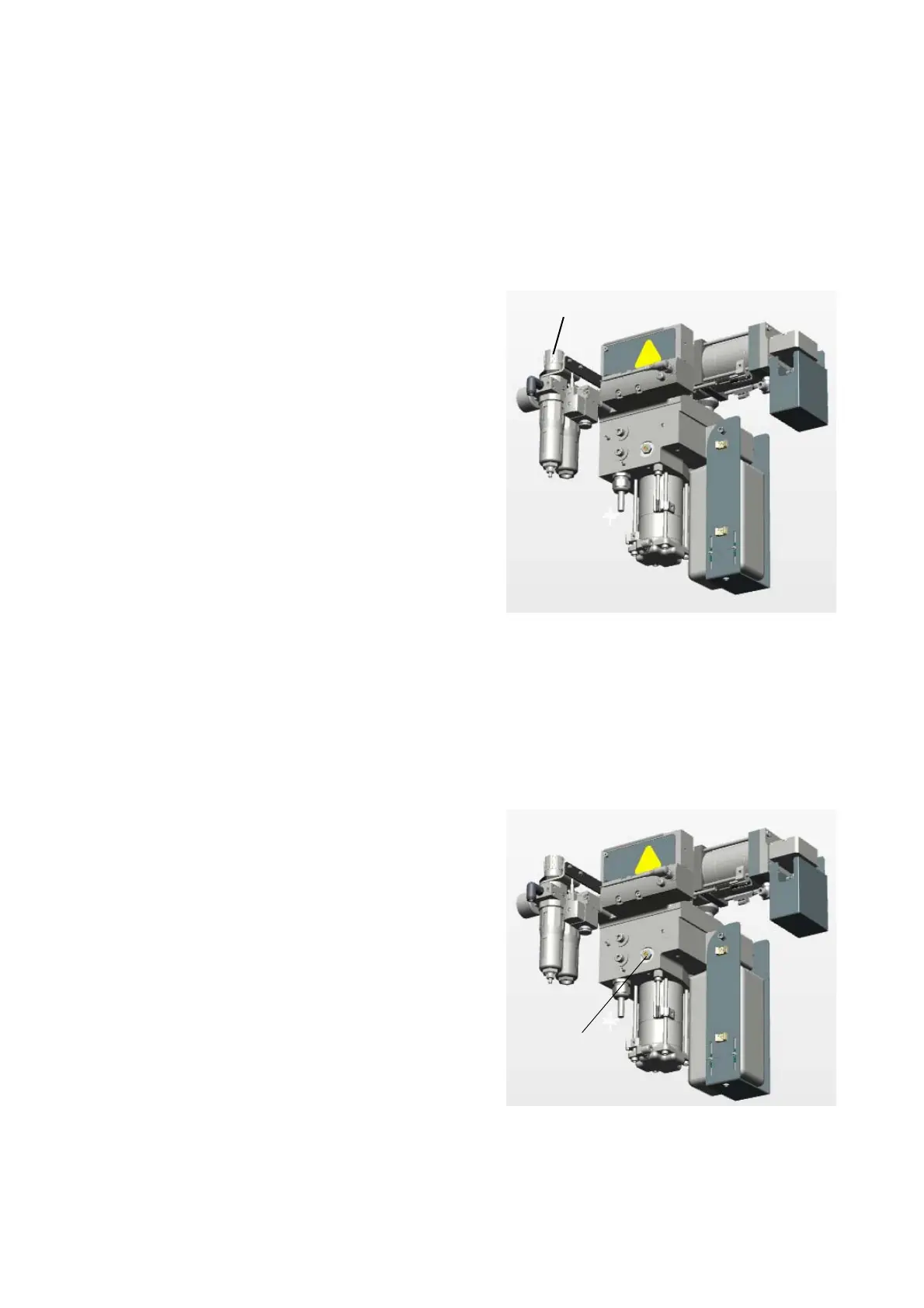

• The operating pressure is set on the mainte-

nance unit (1) for the complete unit and

should no longer be changed.

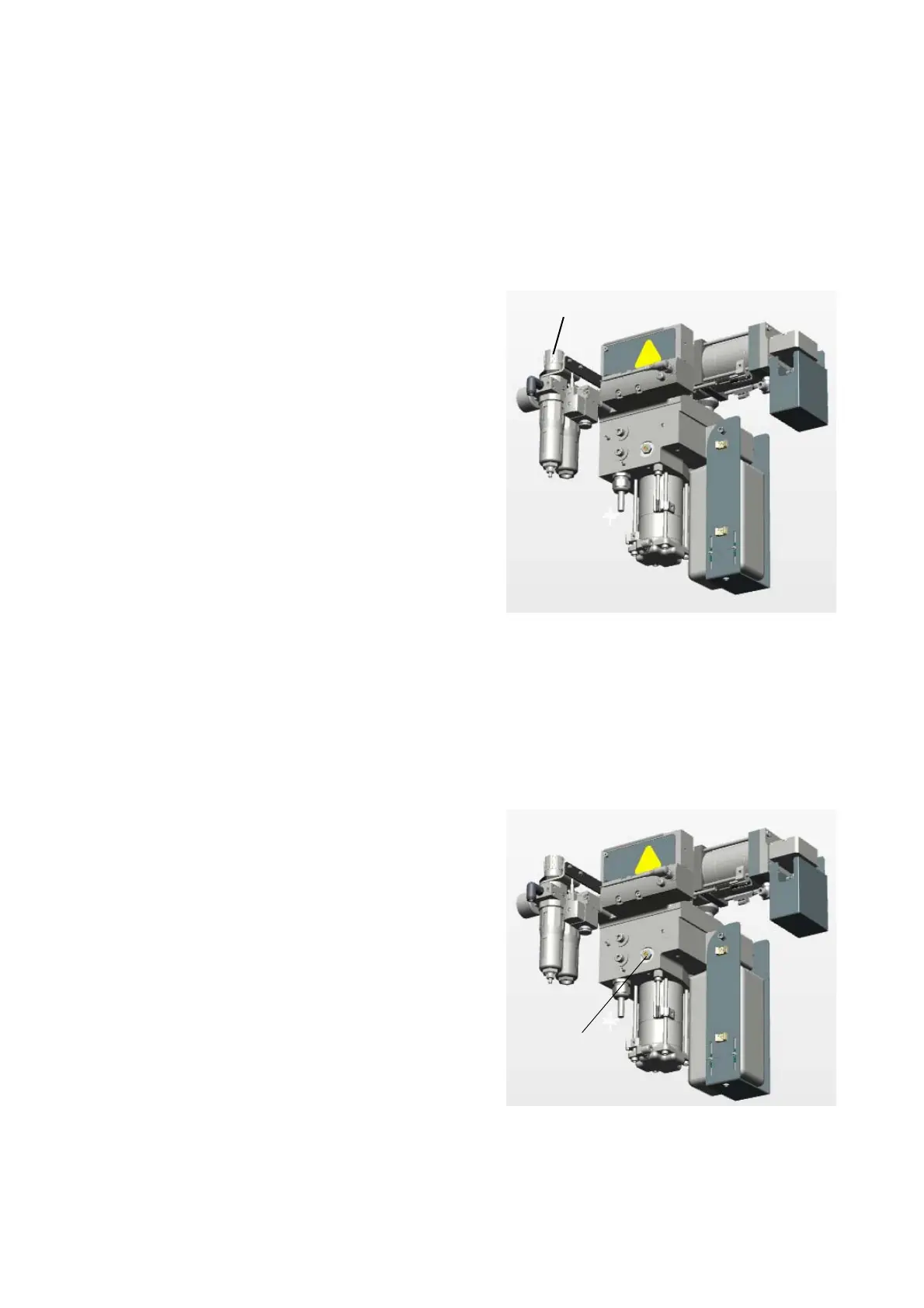

• The quantity of oil through-flow at the oiler

should be one drop per 6-10 cleaning cycles

and the air motor and the pneumatic cylinders

should be adequately lubricated.

• Milling cutter fed and milling cutter speed are

set on the air exhaust throttle valve (1) .

• The cleaning time is controlled through the

cleaning program in the robot control.

• The feed rate is approx. 20 mm/sec, i.e.

approx. 2-2.5 sec is to be set for 45 mm

stroke.

• The completed stroke is reported by the sen-

sor.

Loading...

Loading...