Maintenance

Torch cleaner TC 2013 3HDA000057A8519-001 2-27

Assembly instructions

2.7 Maintenance

The TC 2013 torch cleaning station is largely maintenance-free due to the use of high-quality com-

ponents. The frequency of individual checks and maintenance work is guided by the particular

conditions of use of the TC 2013.

We recommend the following maintenance plan to guarantee perfect functioning of the TC 2013.

I

*) Mineral oil in accordance with DIN 51524-HLP 32, viscosity 32 cST at 40°C

**) Use only AS 72-K genuine spatter release agent!

Before servicing and maintenance work the TC 2013 is

to be made pressure-less and disconnected from the

power supply and protected against being switched

back on.

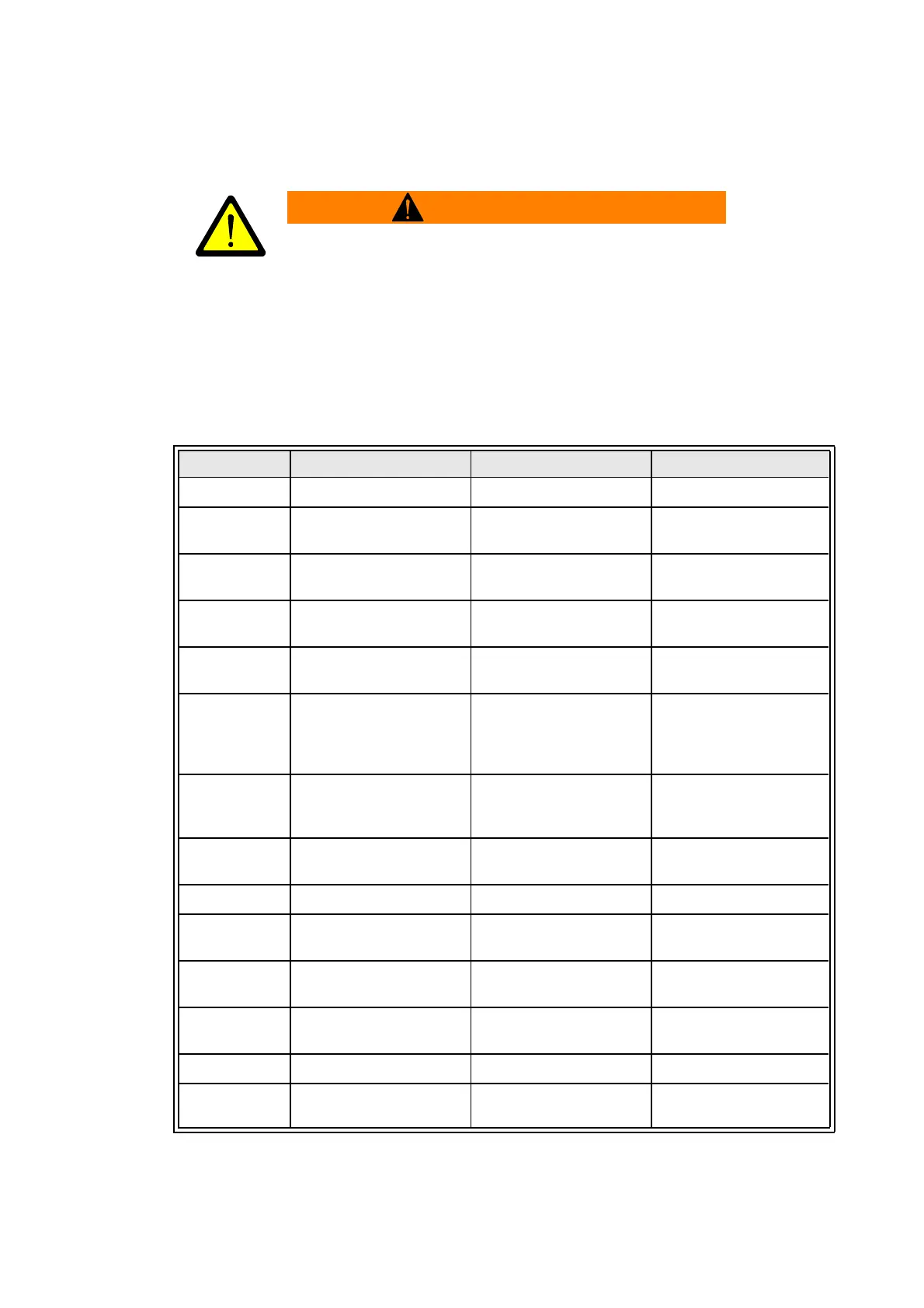

Interval Machine part Activity Remark

daily TSC 2013 Visual inspection

weekly Spray nozzle - Test,

- Clean when required

Milling cutter unit - Test,

- Clean when required

Do not use compressed

air

Maintenance unit

pressure regulator Check pressure

Values see Chapter 2.2

Technical data of TC 2013

Maintenance unit

oiler Check fill-up quantity

Mineral oil to DIN 51524-

HLP 32

Release agent container - Check fill-up quantity

- Visual inspection on

damage

- Exchange when required

ABB ordering No

0.743.505.003 **

Cutting knife - Clean with brush and

grease lightly

- Check on wear

Grease

Milling cutter Check on wear, damage

and firm seating

Wire collecting container Regularly empty

monthly Emergency stopping

devices

Test emergency stopping

devices for function.

Maintenance unit

air filter Check on pollution

Cable and connector Check for damage and

buckling.

V-block TC 2013 Check on wear

2 annual Release agent container Exchange of the container ABB ordering No

0.743.505.003 **

Loading...

Loading...