102 Rockwell Automation Publication 1734-UM013N-EN-P - September 2017

Chapter 5 Configure the Module in a GuardLogix Controller System

The channel offset can be any value from -32768…32767 (engineering

units) in increments of 1. Configure an offset when differences in the

sensors nominal input signals would otherwise exceed the desired

deadband. The channel offset is applied from the second to the first

member of the channel pair, that is, from channel 1 to channel 0 or from

channel 3 to channel 2.

6. In the Input Error Latch Time field, enter the time that the module holds

an error to make sure that the controller can detect it (0…65,530 ms, in

increments of 10 ms - default 1000 ms).

This setting provides more accurate diagnostics. The purpose for latching

input errors is to make sure that intermittent faults that can exist only for a

few milliseconds are latched long enough for the controller to read. The

amount of time to latch the errors must be based on the RPI, the safety

task watchdog, and other application-specific variables.

7. Click Apply.

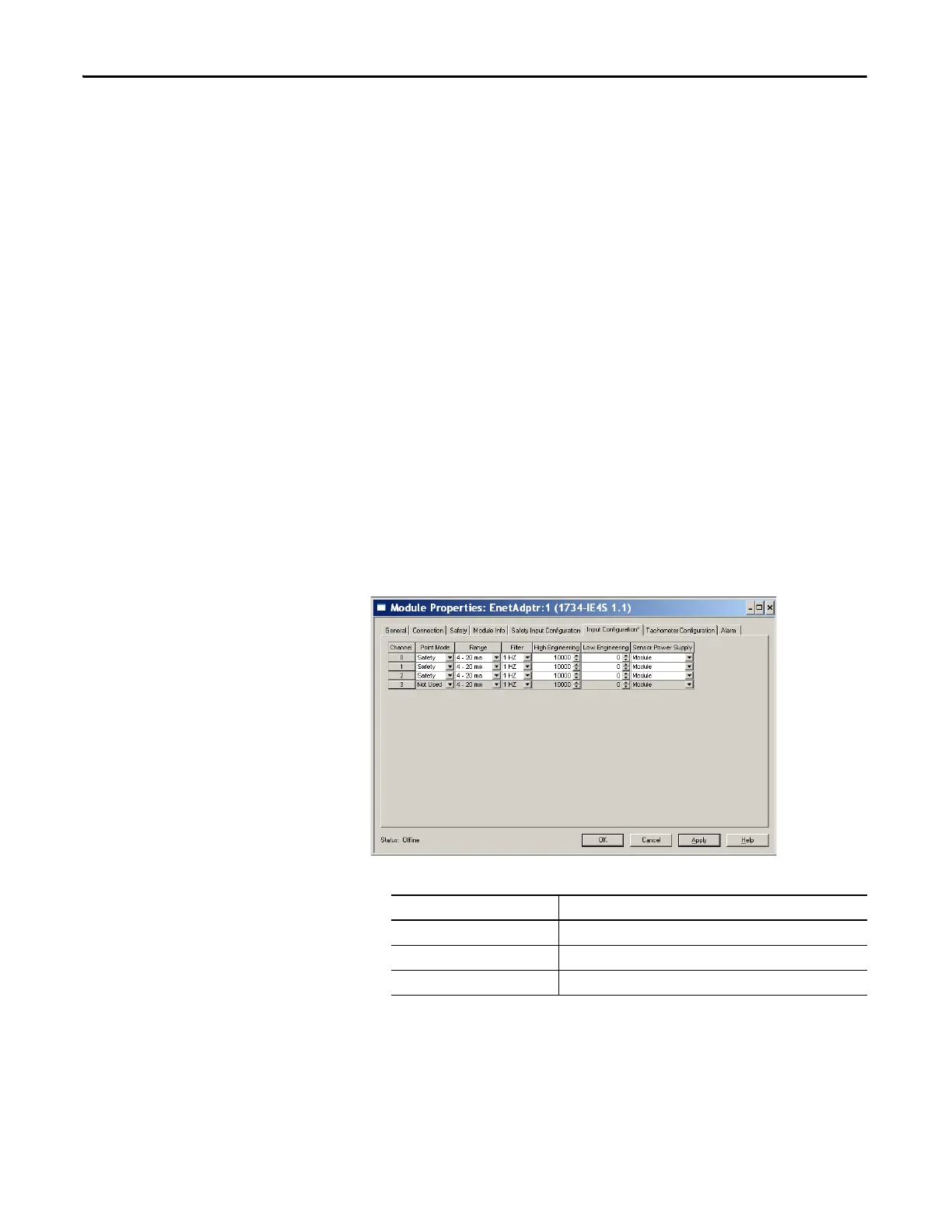

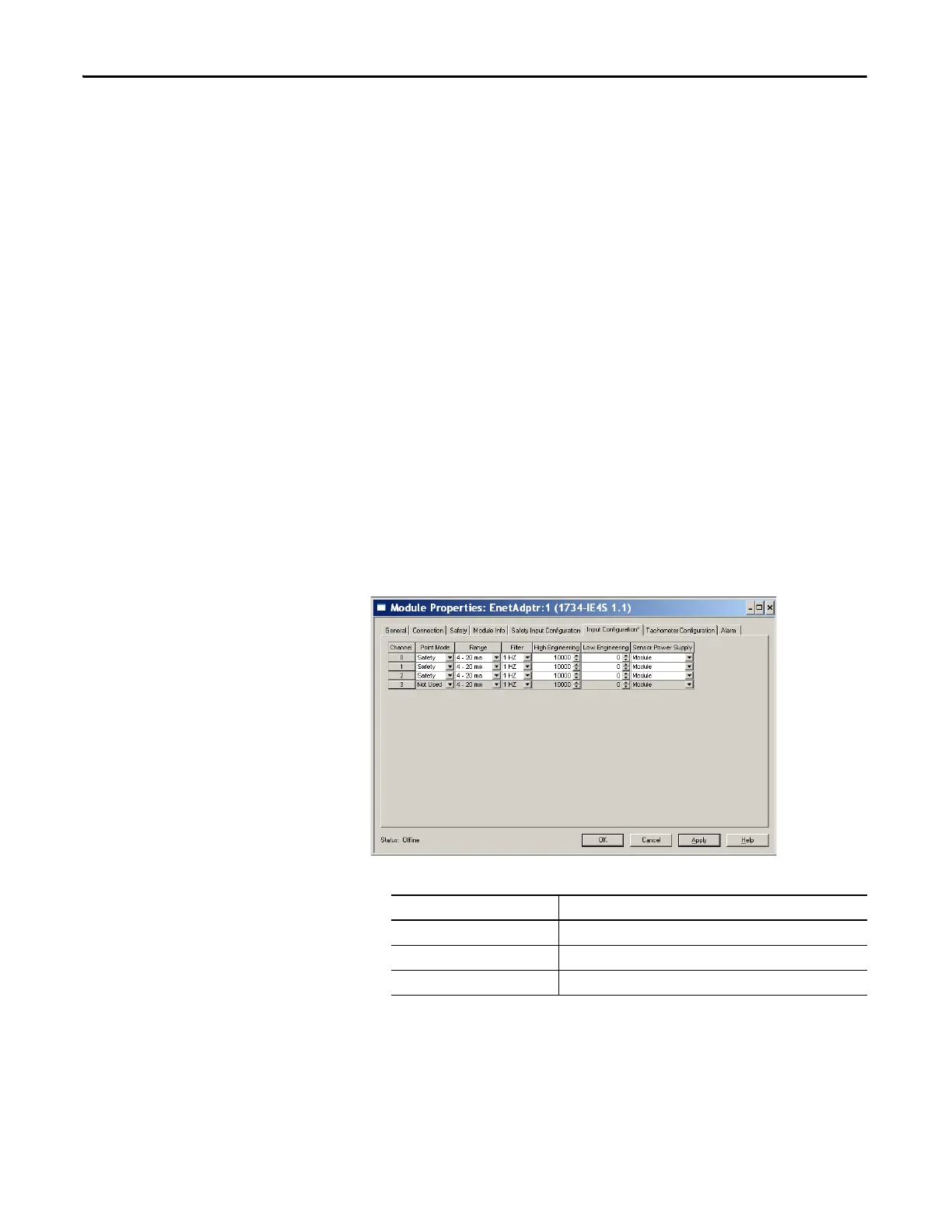

Configure the Safety Analog Inputs

To configure the analog input points, follow these steps.

1. From the Module Properties dialog box, click the Input Configuration tab.

2. Assign the Point Mode.

If the channel operation is configured as dual-channel equivalent, when

you click Apply, channel 1 is set to the same value as channel 0 and channel

3 is set to the same value as channel 2.

3. Configure the module for current, voltage, or tachometer inputs.

Choose Description

Not Used The input is disabled.

Safety Safety-related analog input value

Standard Standard analog input value, not being used for a safety function

Loading...

Loading...