150 Rockwell Automation Publication 1734-UM013N-EN-P - September 2017

Chapter 8 Replacing POINT Guard I/O Modules

The following, simplified example shows Guard I/O™ modules on a DeviceNet

network. Your products can differ, but the function is the same.

Manually Setting the Safety

Network Number

The previous examples showed how the SNN is used to provide safety-

connection integrity after the system is operational. But the SNN is also used to

provide integrity on the initial download to the POINT Guard I/O module.

If a safety signature exists, then the POINT Guard I/O module must have a

proper SNN/node number identification that matches the module within the

safety controller project, before it can receive its configuration. And to keep

integrity, the SNN setting of the module is required to be a manual action. This

manual action is to use the ‘set’ function on an out-of-box POINT Guard I/O

module.

The DeviceNet network supports 64 node numbers, so if you have 100 devices on multiple

DeviceNet networks, there are at least 36 duplicate node numbers being used. Even though the

duplicate nodes are on separate DeviceNet networks, it must still be considered in a safety

system.

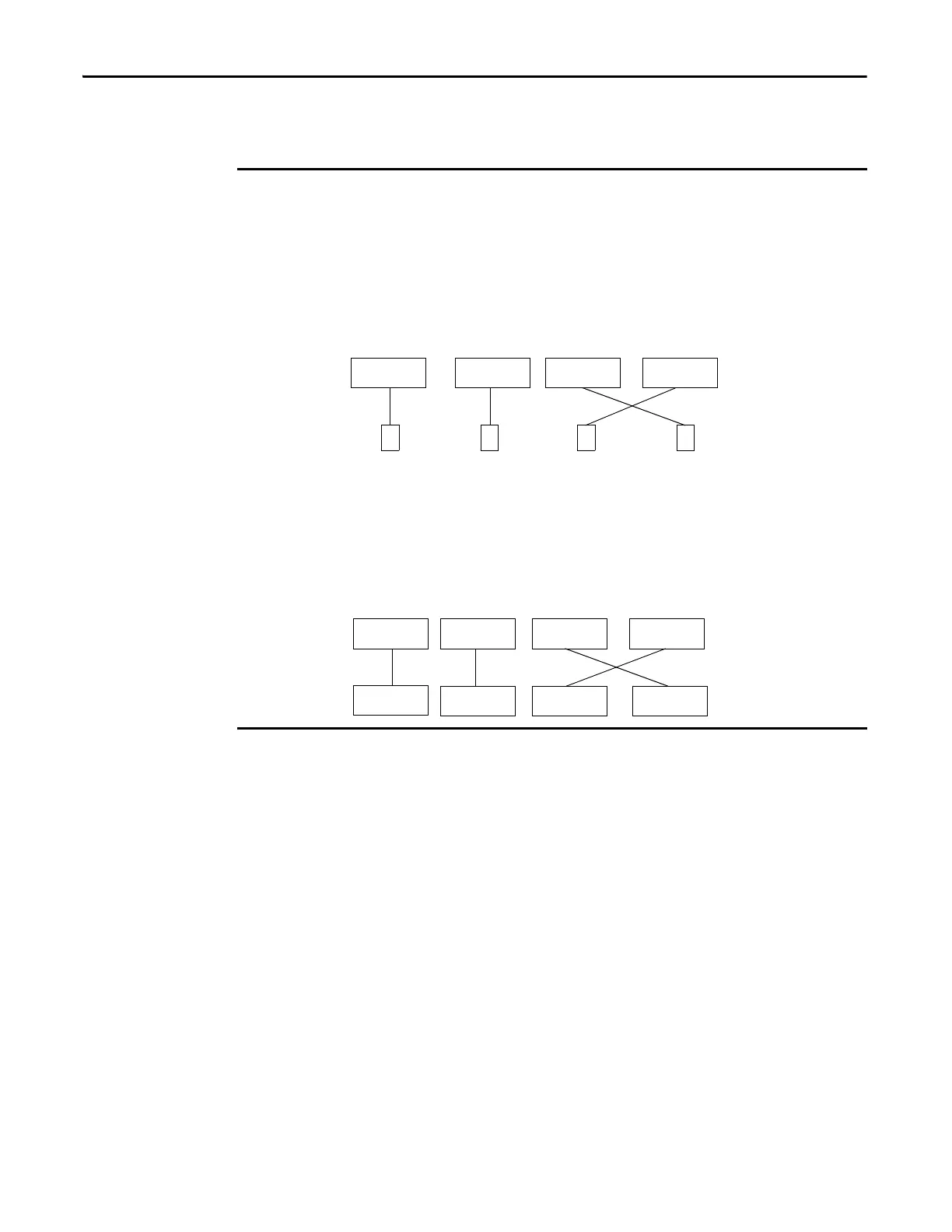

In this example, the DNB scanner #1 is connected to node 5. The DNB scanner #2 is connected to

another node 5. If the cables get inadvertently crossed, the scanners can be communicating with

the incorrect node 5.

Crossed Cables

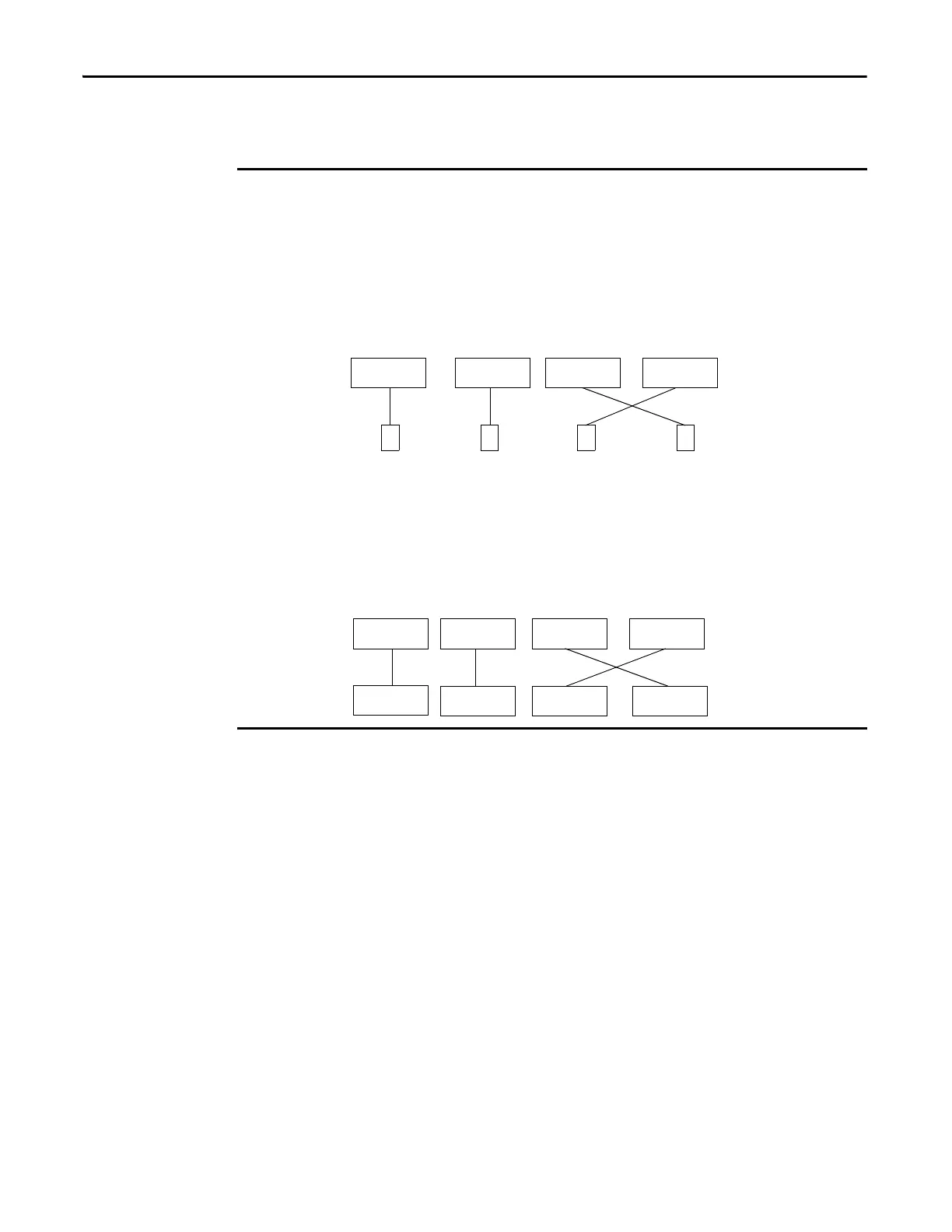

This crossed-cable scenario is unacceptable for a safety system. The SNN provides unique

identification of every safety device. In this next example, all devices that are connected to DNB

scanner #1 have an SNN of 100. All devices that are connected to DNB scanner #2 have an SNN of

101. If the cables get inadvertently crossed, the node connected to DNB scanner #1 changes from

100/5 to 101/5. The node that is connected to DNB scanner #2 changes from 101/5 to 100/5.

Therefore, the safety connections are not made if the cables get crossed.

Connections Not Made

DNB #1 DNB #2 DNB #1 DNB #2

5555

DNB #1 DNB #2 DNB #1 DNB #2

5

SNN 100

5

SNN 101

5

SNN 100

5

SNN 101

Connections not

made.

Loading...

Loading...