38 Rockwell Automation Publication 1734-UM013N-EN-P - September 2017

Chapter 2 Safety Inputs, Safety Outputs and Safety Data

Tachometer Mode

In Tachometer mode, the module measures digital pulses between 0 and 24V

DC and converts them into a frequency or pulses per second. Therefore, you can

use 24V DC proximity sensors or 5V DC encoders, for example. The

Tachometer function does not sense direction, so using a differential encoder

does not yield direction data. Tachometer mode could be used, for example, to

measure rotational speed of an axis that is connected to a gear.

Tachometer mode can operate as SIL 2 single-channel. SIL 3 is achievable by

using two sensors, the dual-low detection parameter, and user program logic.

Safety reaction time is dependent on the signal frequency.

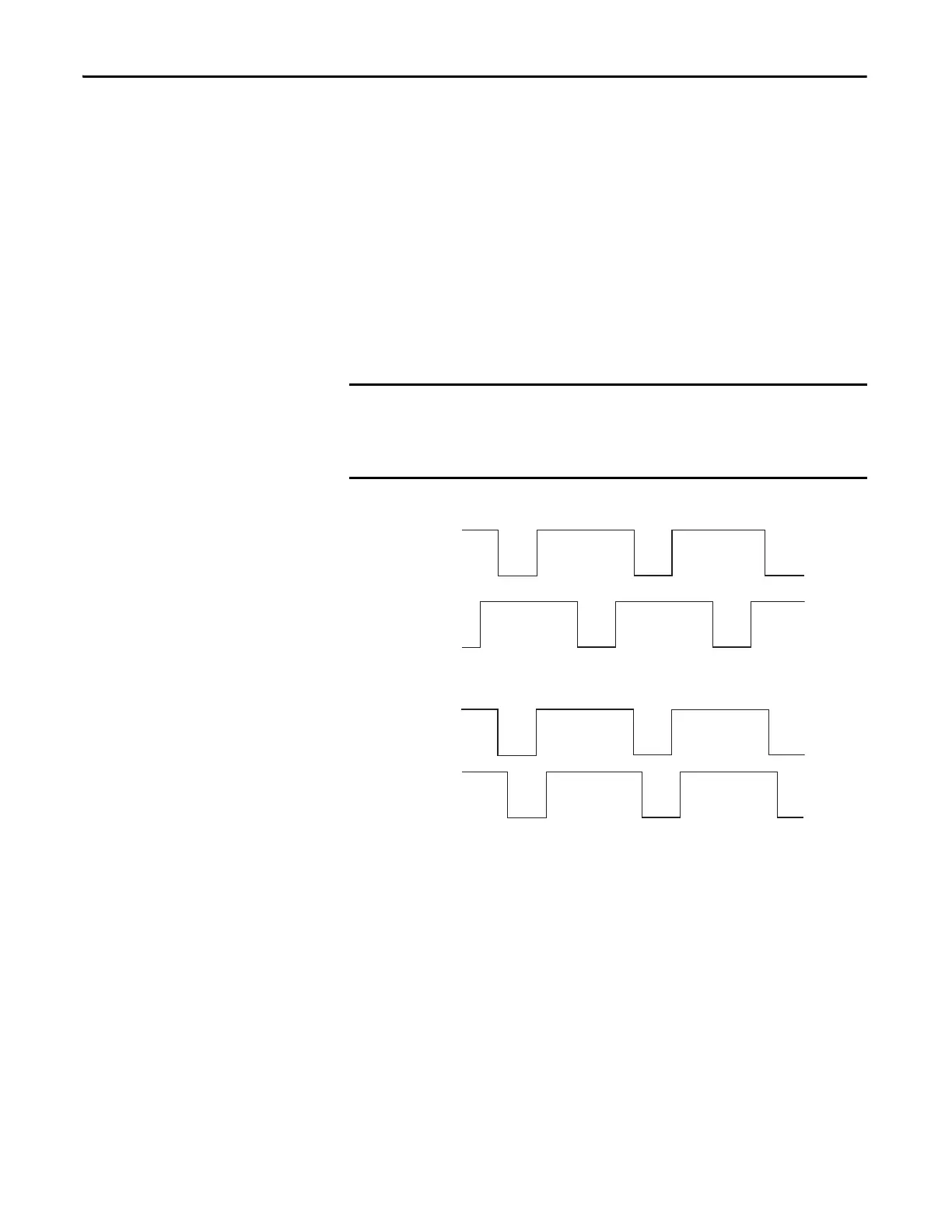

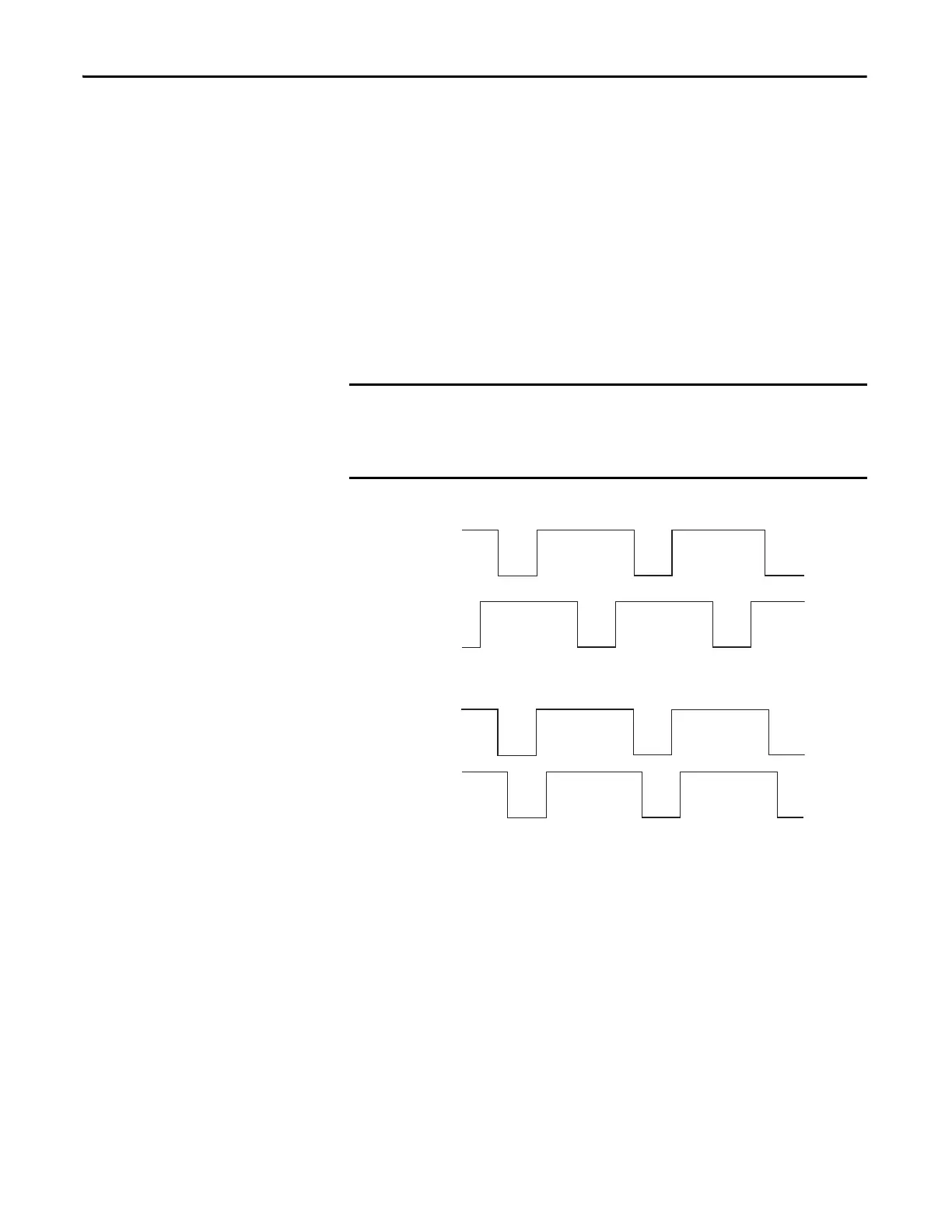

Figure 15 - Sensor Pulses in Dual-channel Configuration

Signal Measurement

The edge-to-edge time of the pulse determines the frequency of the signal in

pulses per second. The frequency range is 1 Hz…1 kHz.

In Tachometer mode, you define how the signal is measured, either on the falling

(non-inverted) or rising (inverted) edge. For NPN-style sensors (sensor sinks),

use falling edge. For PNP-style sensors (sensor sources), use rising edge.

Depending on your application, you need to install an appropriately sized pull-up

resistor for falling-edge signal measurements or a pull-down resistor for

rising-edge signal measurements.

When using two sensors in a dual-channel configuration, position the sensors

to make sure that the low pulses occur at different times. If you have

configured the module for dual low detection and both sensors are low

simultaneously, a fault is declared.

Low pulses are offset.

Sensor 1

Sensor 2

Low pulses occur simultaneously, causing a fault.

Sensor 1

Sensor 2

Loading...

Loading...