Asynchronous motors - Special functions

Function description 13

Version: 1.5

3.2.1 Functionality from firmware v2.03

Mode of functioning of the breakdown protection controller

The breakdown protection controller attempts to avoid the impermissible range (actual current value

I

max

in %). This is defined in advance in parameter P-0-0115 (ASM: stall protection loop, torque limit value). If

a machining procedure exceeds the I

max

value, the servo drive reduces the set speed (reduction to ≤ 0 is

possible). The mode of functioning is illustrated in detail in the following practical examples 1 and 2. The

procedure concerned is always a machining procedure on a milling machine. A tool penetrates solid material

on reaching the speed setpoint:

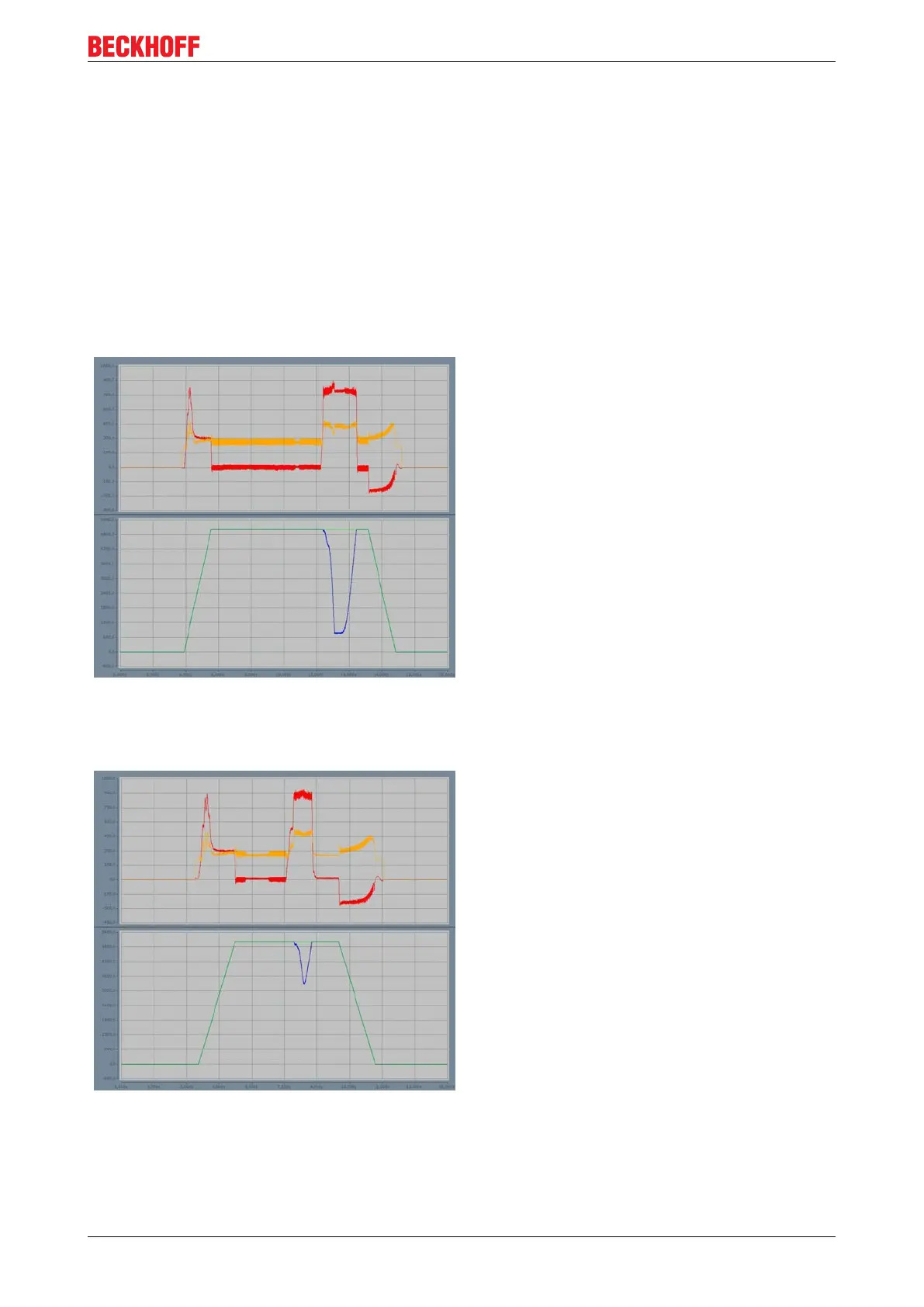

Practical example 1

Machining procedure with an actual current value I

max

of 90%

The value of the breakdown protection controller is

set to 90% in example 1. As the tool penetrates the

solid material, you can see by the blue characteristic

curve that the speed drops dramatically at this point.

Result:

The limitation of the current to 90% by the breakdown

protection controller is therefore insufficient to

maintain the set speed.

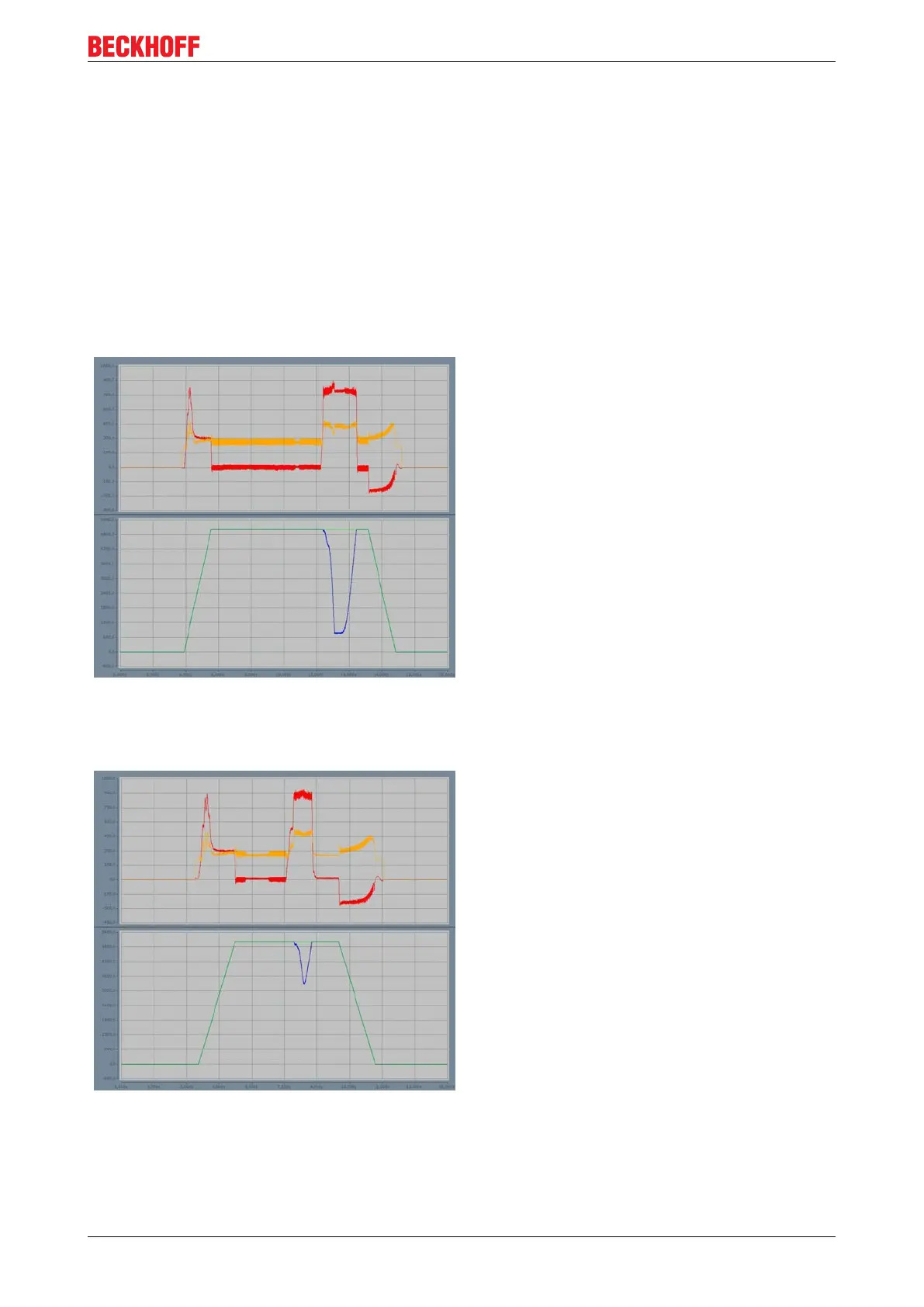

Practical example 2

Machining procedure with an actual current value I

max

of 100%

The value of the breakdown protection controller is

set to 100% in example 2. As the tool penetrates the

solid material, you can see by the blue characteristic

curve that more current is available at this point and

that the speed does not drop as dramatically as in

example 1.

Result:

The consequence of the limitation of the current to

100% by the breakdown protection controller is that

the set speed can be maintained better.

Key:

- Green characteristic curve: Set speed

- Blue characteristic curve: Actual speed

- Red characteristic curve: Active current (maps the torque)

- Yellow characteristic curve: Reactive current (maps the magnetization)

Loading...

Loading...