Modulo

Function description52

Version: 1.5

11.3 Parameterisation

11.3.1 Activating the modulo function

Valid parameterization of the modulo function necessitates the setting of IDNs in the AX5000 as well as

corresponding parameterization of the NC or CNC. It is recommended to commission the modulo function

with the help of the TcDriveManager, since this also sets the NC or CNC parameterization correctly. The

procedure when using the TcDriveManager is described below.

The following IDNs are used for the parameterization of the modulo function:

S-0-0076 - "Position data scaling type"

The modulo function is activated with the bit "Processing format" in IDN S-0-0076 "Position data scaling

type".

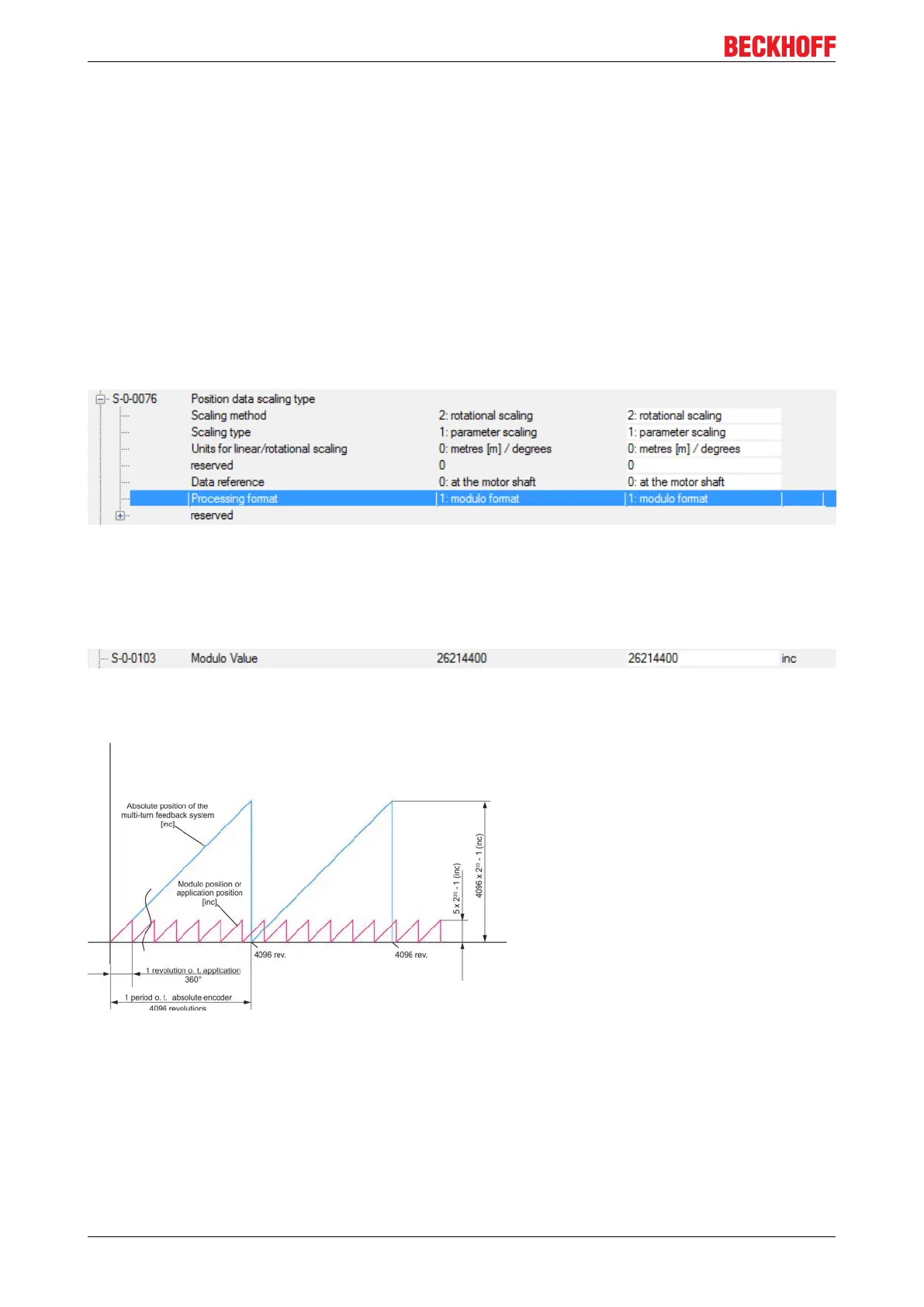

S-0-0103 - "Modulo Value"

The maximum calculated value for an application period is entered in IDN S-0-0103 “Modulo Value”. The unit

is "inc", and 2

x

inc (where x = [20 to 30], see S-0-0079) correspond to one motor revolution. For the

conversion please take into account the gear ratio of any gear unit installed after the motor. Accordingly, the

maximum modulo position is S-0-0103 - 1 inc. Please note that S-0-0103 must be > S-0-0079.

In this example a multi-turn absolute value feedback system with 4096 turns and a gear unit with a gear ratio

of 1:5 is used. 5 motor revolutions correspond to 1 application revolution. In this case the maximum modulo

position is 5 x 2

20

- 1 inc, for S-0-0103 = 5 x 2

20

.

Loading...

Loading...