CVT Drive and brake system

59

• When the brakes are released, it should be pos-

sible to wiggle the brake rotor within the yoke.

• If the rotor is tight in the caliper, check the yoke

adjustment.

• If the rotor is tight in the yoke, check the opera-

tion of the yoke to confirm that it is not stuck.

• When the brake pedal is released, the brake arm

on the yoke should fall completely back against

the axle housing.

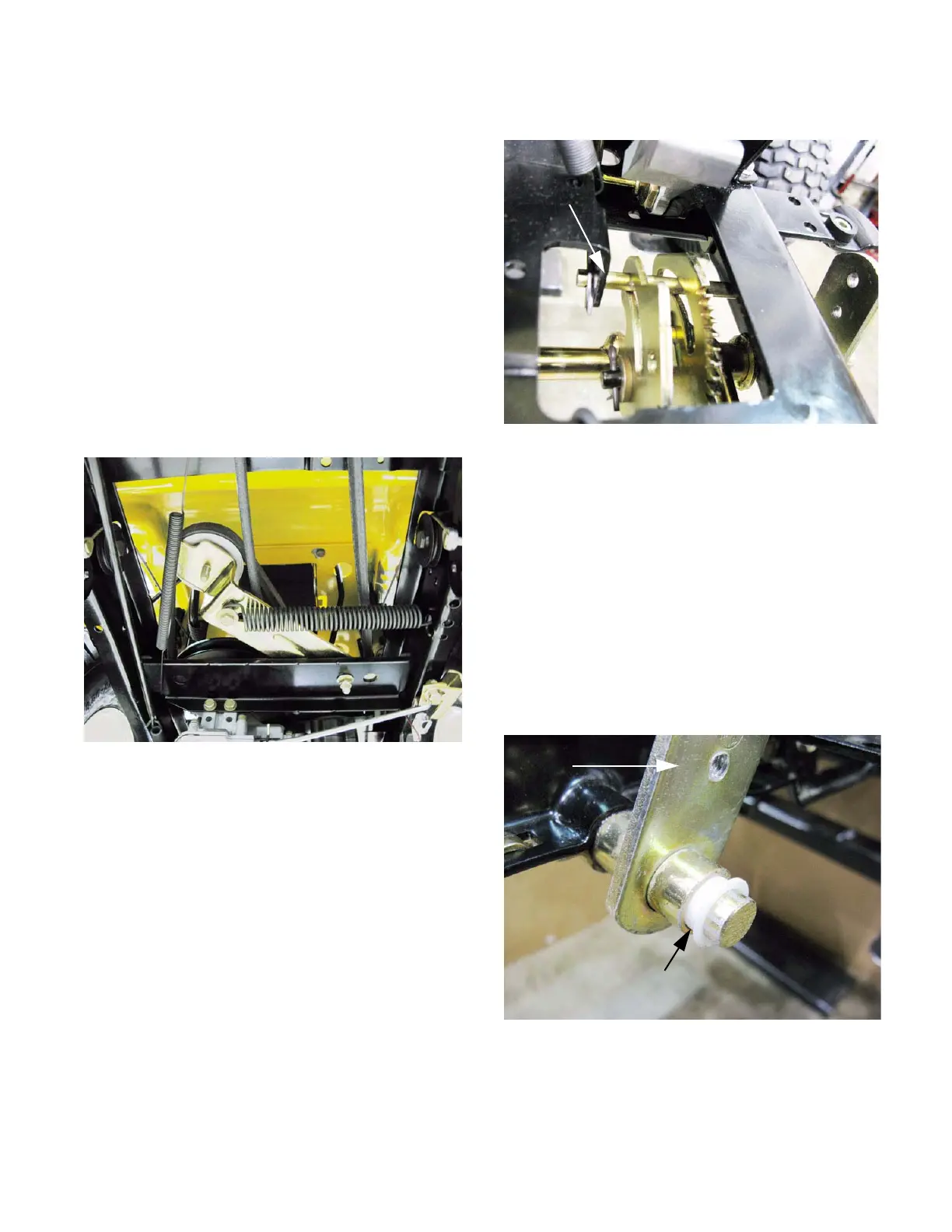

4. Check the drive belts. See Figure 6.4.

• In normal use, drive belts typically last for years

without problems.

• If the belt fails prematurely, identify and correct

the cause of the belt failure before returning the

tractor to service.

4a. Look-up the part number for the belts, and

confirm that the correct OEM belts are on

the tractor.

4b. Check the belt routing.

4c. Check the brake/clutch linkage and belt

tensioning pulleys.

4d. Check for foreign objects jammed against

the belt.

4e. Check for missing or out-of-place belt

guides. See the belt replacement section

of this chapter.

4f. Check the engine crankshaft and transaxle

input pulleys; Confirm that the sheaves are

not spread-out, causing a loose belt fit.

Figure 6.4

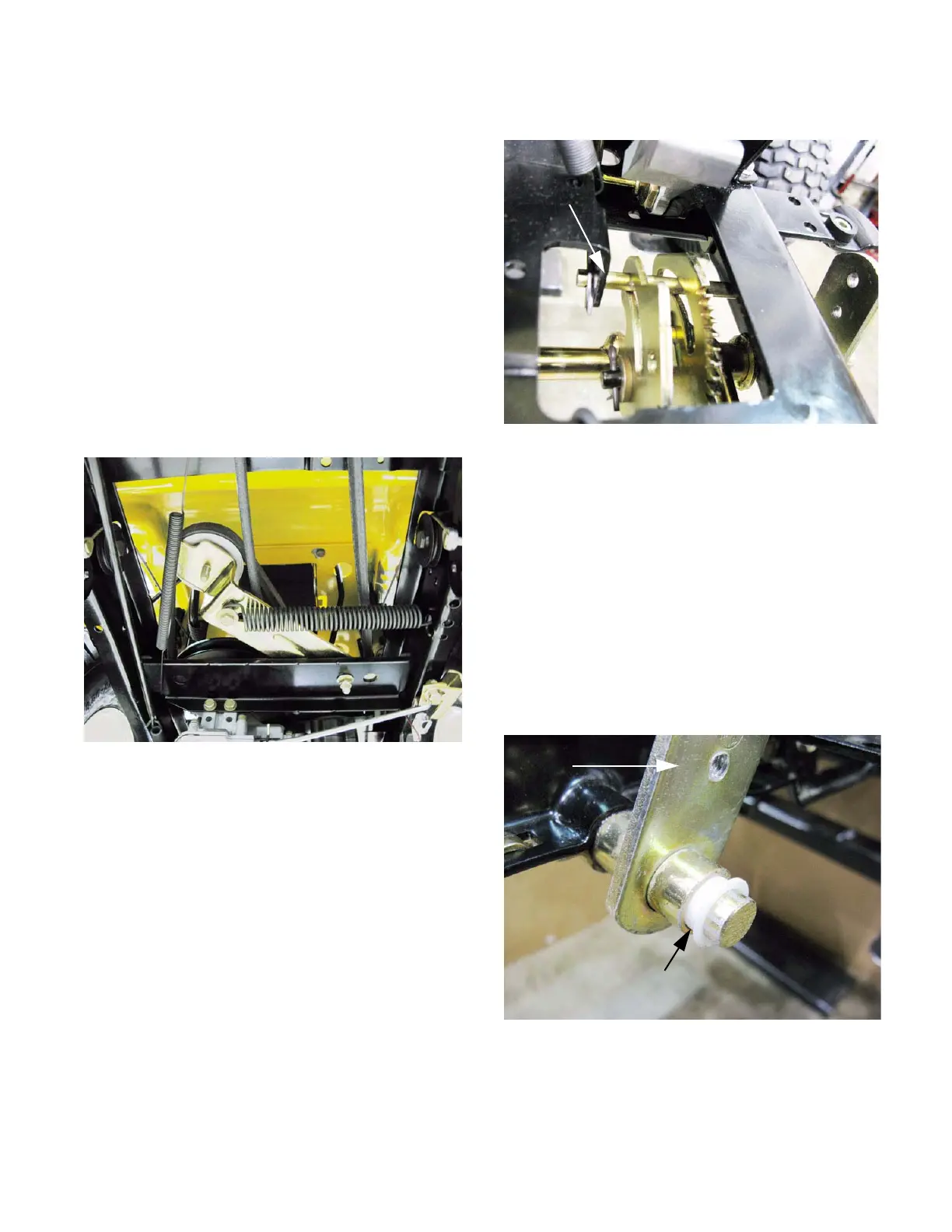

5. Check the drive control linkage. See Figure 6.5.

5a. The travel limit pin fits into the curved slot

in the drive pedal latch plate. The pedal

bracket should have enough travel for the

pin to hit both ends of the curved slot when

the pedal is moved through the full range

of its travel.

5b. Some relatively simple things that may go

wrong with the pedal linkage:

• The drive pedal itself being loose on the bracket.

• Worn plastic bushings between the drive pedal

bracket and the brake cross-shaft.

See Figure 6.6.

5c. Check the adjustment of the front ten-

sioner pulley control rod.

Figure 6.5

Travel limit pin

Figure 6.6

Plastic bushing

Pedal mounting

bracket

Loading...

Loading...