HEADLIGHT VOLTAGE INSPECTION

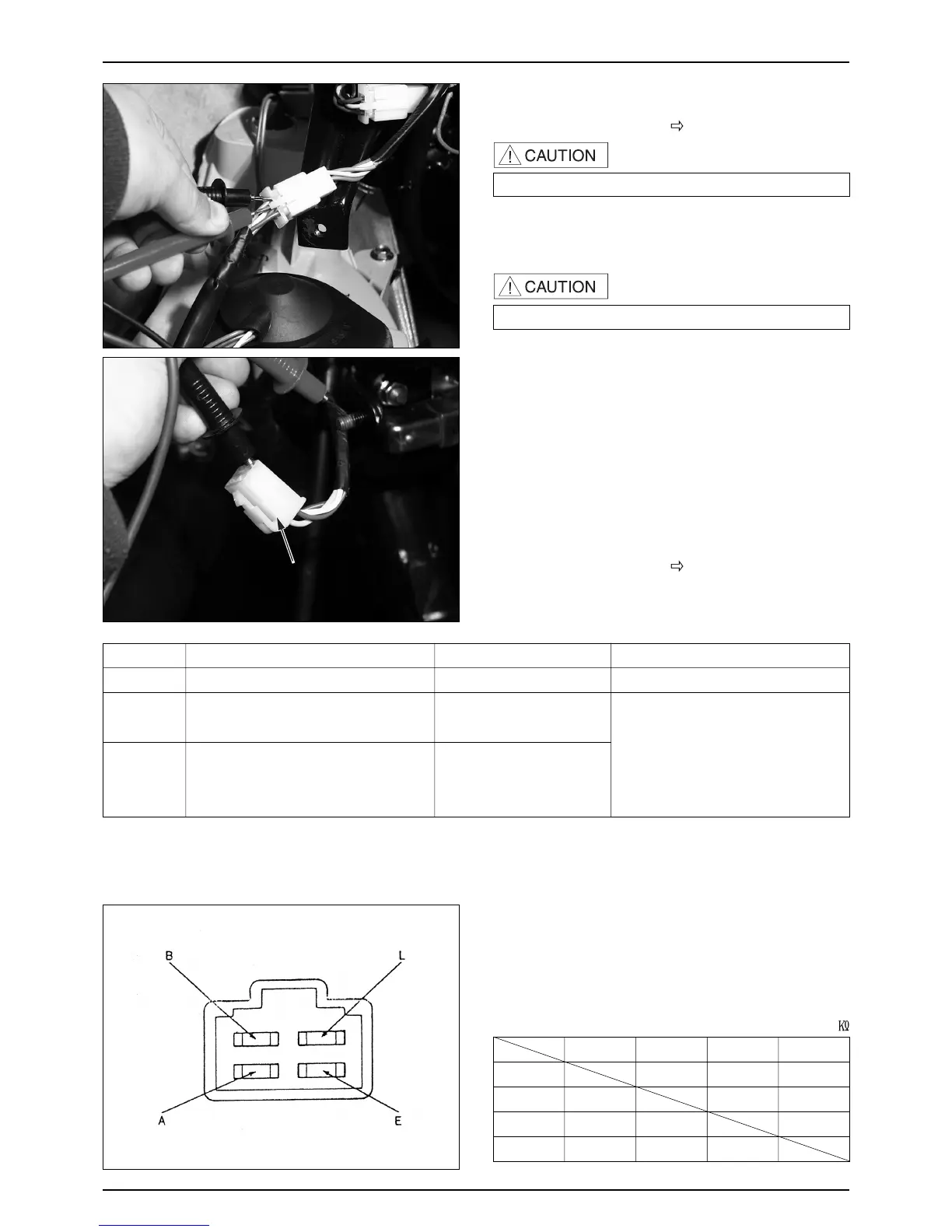

● Remove the front cover. ( 3-5)

·Check voltage with the headlight coupler connected.

● After starting the engine, place the dimmer switch to

HI and check the voltage between the blue (+) and

green (-) wires of the headlight coupler.

·Measurement is performed in AC area.

CONTROL VOLTAGE : 12.6~13.6V/5,000rpm

● If voltage is incorrect, check the regulator/rectifier.

REGULATOR/RECTIFIER INSPECTION

HARNESS CIRCUIT INSPECTION

● Remove the front cover. ( 3-5 )

● Remove the 4P coupler of the regulator/rectifier and

inspect the wiring circuit in the main harness side

terminal.

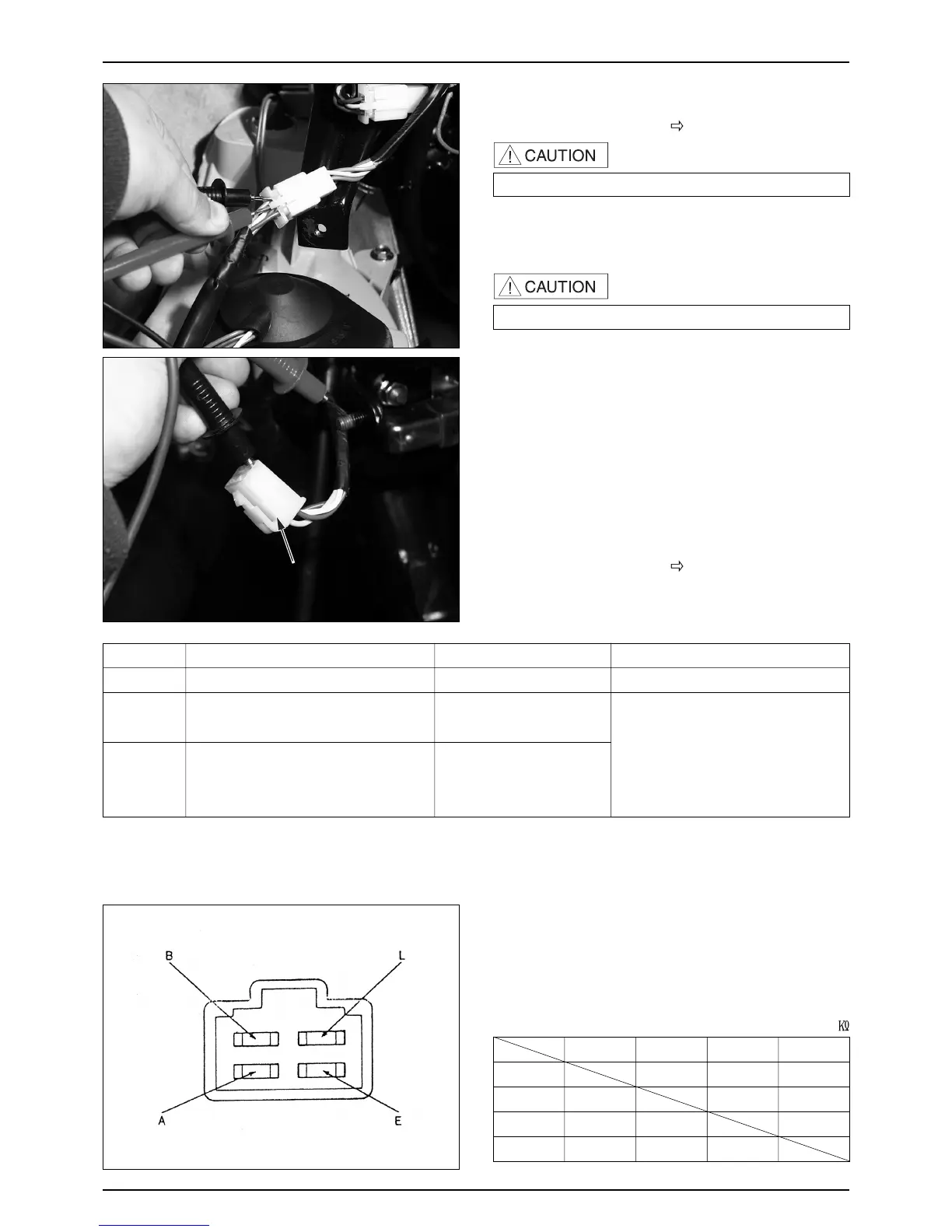

REGULATOR/RECTIFIER INSPECTION

● If the inspection of the harness side proves to be

satisfactory, check the regulator/rectifier coupler for

faulty connection, and measure the resistance between

the terminals of the regulator/rectifier.

13-6

CHARGING SYSTEM/A.C.GENERATOR

ITEM

BATTERY WIRE

CHARGING

COIL

LIGHTING

COIL

Voltage between red “⊕” and green “⊖”.

※ Resistance between white wire and

earth wires. Disconnect the starter.

※ Resistance between yellow wire and

earth wires. Disconnect dimmer

switch connection

Damaged, disconnected main fuse/harness.

AC generator (charging, lighting coil

coupler connection damage) resister(

6.7Ω

5W) headlight lighting circuit.

There must be battery voltage.

0.4~1.0Ω(20℃)

0.2~0.8Ω(20℃)

MEASUREMENT LOCATION LEVEL

AREAS OF INSPECTION IF INCORRECT

ALB E

A ∞ 3-50 ∞

L ∞∞5-100

B ∞∞ ∞

E ∞ 5-100 ∞

Inspect ※ part after at least 10 minutes later.

RESISTANCE VALUE

Tester ⊕

Tester ⊖

(

20℃

) Unit :

(BATEERY TERMINAL)

TERMINAL ARRANGEMENT

(LAMP TERMINAL)

(EARTH TERMINAL)(CHARGING TERMINAL)

Loading...

Loading...