9-1

9. TRANSMISSION/CRANKSHAFT/CRANKCASE

SERVICE INFORMATION

GENERAL SAFETY

● This section describes how to remove the crank case and to maintain the transmission and the crankshaft.

● Always use special tools to change the drive shaft. Fix the bearing inner race, andn install the shaft.

● The following parts must be removed prior to removing the crank case. Follow the removal procedure specified in each

section.

-OIL PUMP (

SECTION 4 )

-CARBURETOR (

SECTION 5 )

-ENGINE (

SECTION 6 )

-CYLINDER HEAD/ CYLINDER/ PISTON (

SECTION 8 )

-AC GENERATOR (

SECTION 13 )

-DRIVE PULLEY (

SECTION 7 )

-CLUTCH/DRIVEN PULLEY (

SECTION 7 )

-REED VALVE (

SECTION 5 )

● The following parts must be removed prior to changing the L. crank case. Follow the removal procedure specified in

each section.

-TRANSMISSION (

SECTION 9 )

-REAR BRAKE (

SECTION 12 )

● To assemble the crank case and crankshaft, set the special tool to the inner race of the crankshaft bearing, and push and

assemble. Remove the bearing from the crankshaft during disassembling work, and insert a new bearing in the case.

Install the oil seal after the case is assembled.

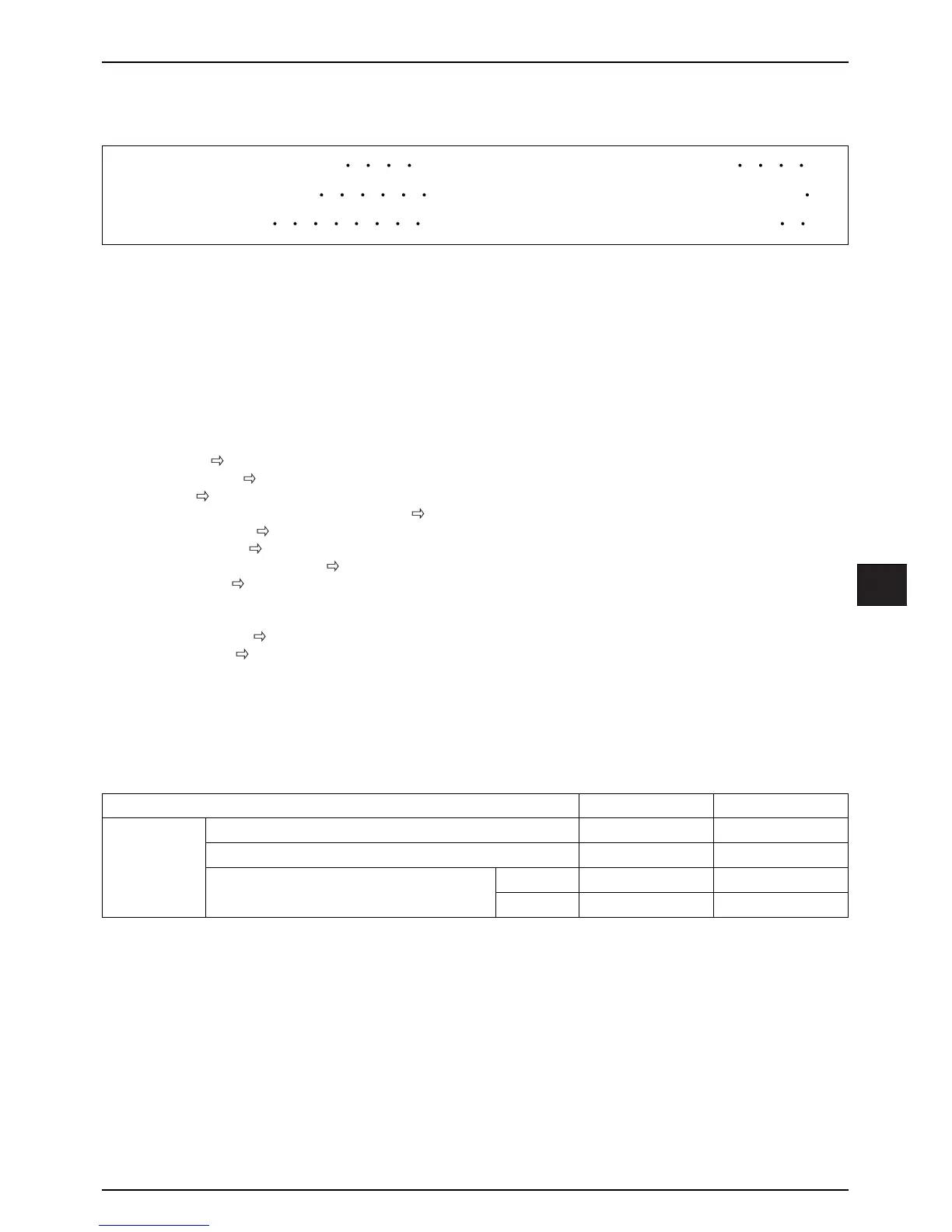

SPECIFICATIONS

TROUBLESHOOTING

Engine Noise

● Clearance in the connecting rod large end portion/small end portion bearing.

● Clearance in the crankshaft bearing.

9

SERVICE INFORMATION

9-1

TROUBLESHOOTING

9-1

TRANSMISSION

9-2

CRANKSHAFT REMOVAL

9-5

CRANKCASE BEARING REMOVAL

9-6

CRANKSHAFT INSTALLATION

9-7

0.15~0.55mm

0.010~0.02mm

0.03mm

0.05mm

0.60mm

0.04mm

0.15mm

0.10mm

ITEM

CRANK

SHAFT

Large end side clearance

Connecting rod large end right angle direction clearance

Crank shaft shaking

Right

Left

STANDARD VALUE SERVICE LIMIT

Loading...

Loading...