150 | © Danfoss | August 2018 AQ00000211

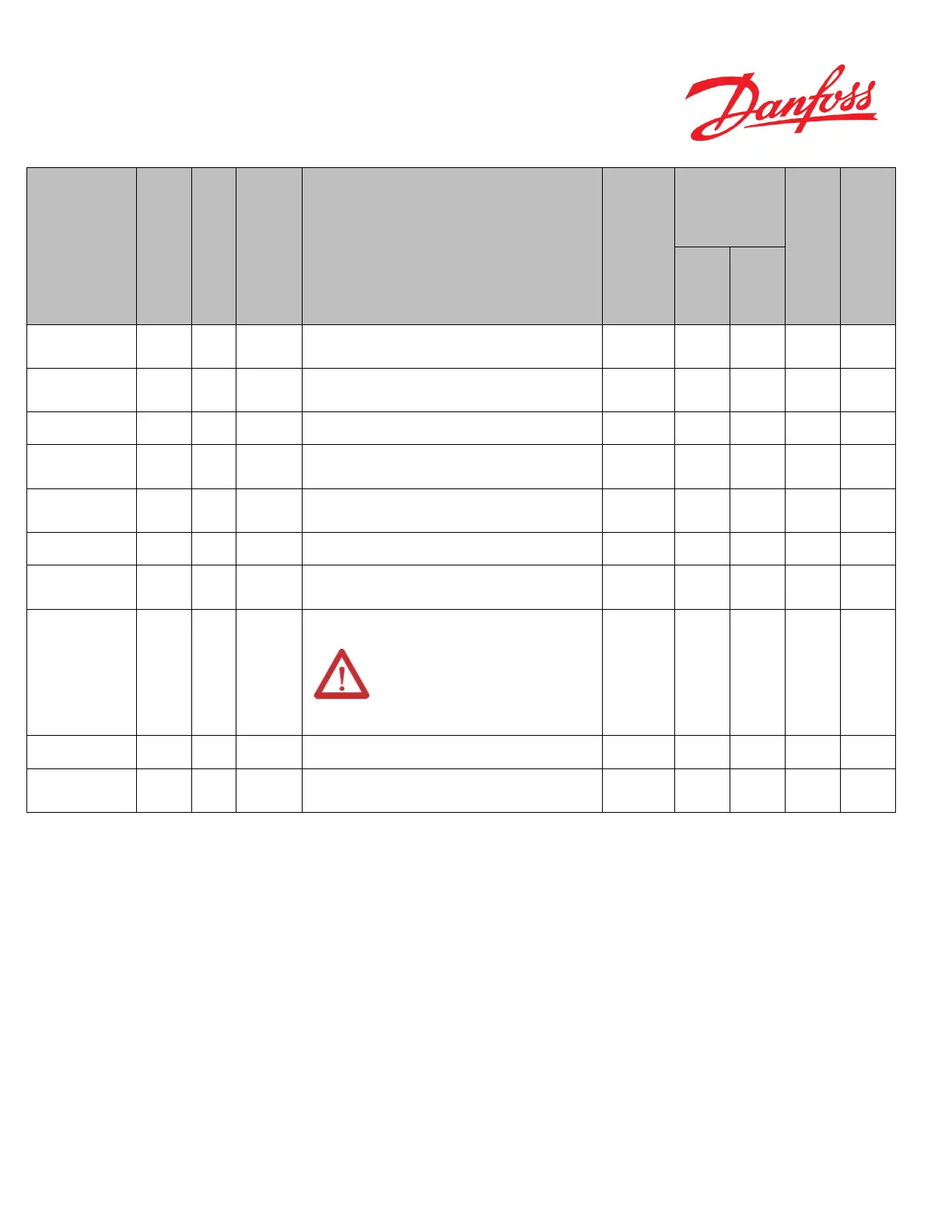

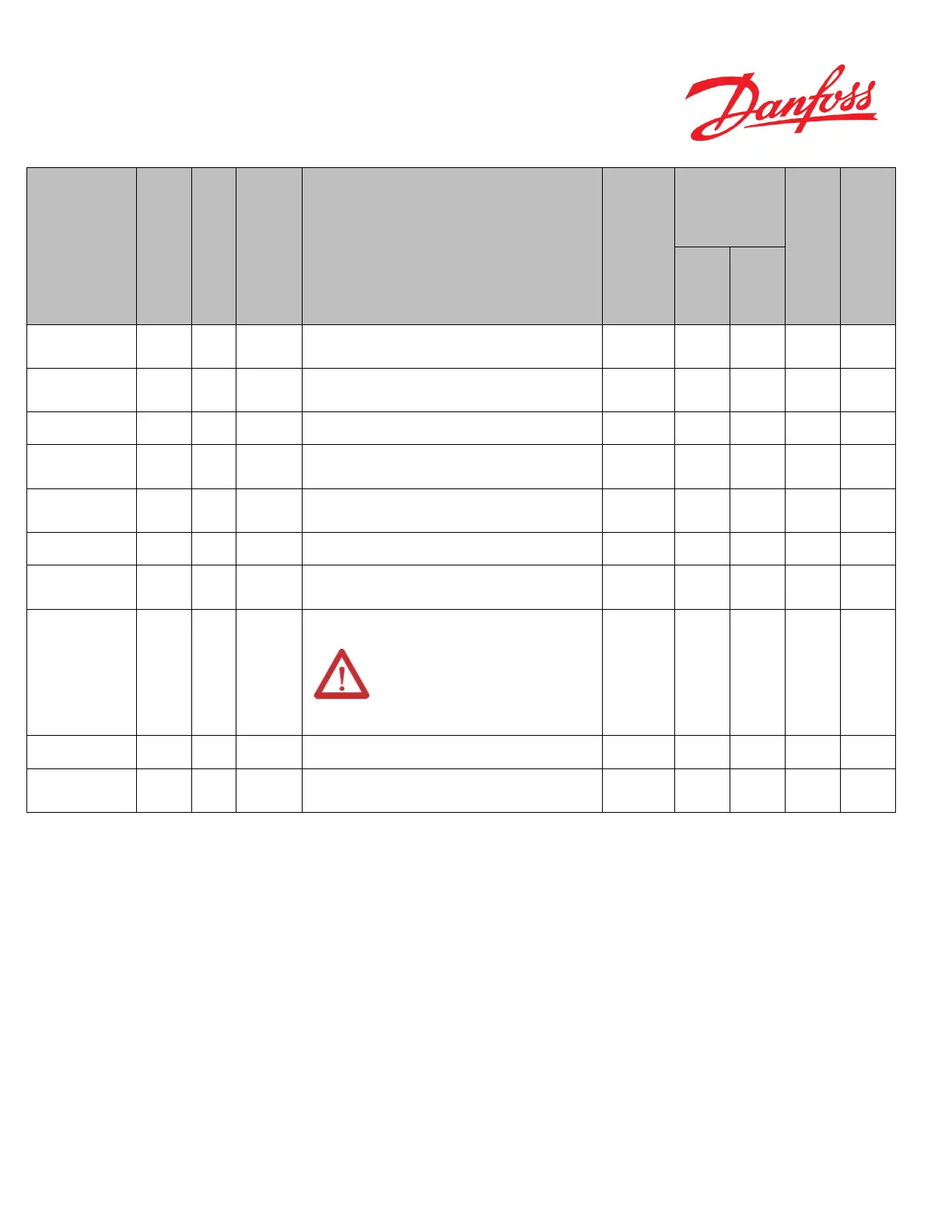

17.4.2 SEHS FDA

Name

Description of parameter

Range

Safety critical

parameters ‘S’

Algorithm - Steering

wheel activation

P3122 U8 dRpm

Steering wheel angle velocity threshold used in the Fault Detection

Algorithm to detect the steering wheel activation

OEM 0 150 5 S

Algorithm – min. wheel

angle movement

P3123 U8 IR

Minimum wheel angle difference necessary to observe in order to make the

Fault Detection Algorithm assume that the wheels are moving. The

difference is calculated between the current WA position and WA number

of loops back. Number is defined by P3124.

OEM 0 200 50 S

Algorithm – wheel angle

P3124 U8 x10mSec

Number of loops between samples that are being compared against P3123

for WA motion determination

OEM 1 20 1 S

Algorithm - Fault

confidence counter

P3125 U8 x10mSec

Rate at which the Fault Detection Algorithm confidence counter value

decreases if an error is no longer observed

OEM 1 10 1 S

Algorithm - Fault

confidence counter

P3126 U16 x10mSec Time period for which error shall be observed by FDA to report failure OEM 0 2000 50 S

Algorithm - Spool in left

P3128 S16 x10u Meter Distance from closed loop dead-band to check if spool in left side OEM -200 200 0 S

Algorithm - Spool in

right position range

P3130 S16 x10u Meter Distance from closed loop dead-band to check if spool in right side OEM -200 200 0 S

Fault Detection

Algorithm - Safe state

upon a failure detection

P3132 U8 -

FDA safe state trigger Enable/Disable after failure detection.

Valid Values: 0 (DISABLE); 255 (ENABLE)

Warning

DISABLE should only be used when diagnosis of the wheel angle

sensor and SASA failure modes are ensured by anther monitoring

function or when getting initial data for FDA tuning

OEM 0 255 0 S

Algorithm - Backlash

P3133 U8 dDeg

Backlash limit to use in the backlash filter in the FDA control algorithm

exclusively

Resolution: 1dDeg = 0.1Deg

OEM 0 200 5 S

Algorithm - Vehicle

speed threshold for

P3134 U8 km/h

Will disable the FDA and spool monitoring if speed of the vehicle goes

below this value. Should only be changed if EHPS/OSPE/EHi system is

underpowered, hence the system does not have enough pressure to move

the wheels (normally when vehicle is not moving)

OEM 0 10 0 S

Table 65

Loading...

Loading...