66 | © Danfoss | August 2018 AQ00000211

9.4.1 Initial setup

WAS:

The function works by capturing the leftmost, rightmost and straight ahead position of the wheels. The function will learn

the relationship between the AD/CAN values of the WAS for the whole steering band (from leftmost position to rightmost

position) and scale this into an internal resolution in steps of 0.1% for the steering (leftmost to straight ahead and straight

ahead to rightmost).

Joystick:

The function works by capturing the leftmost, rightmost and neutral position of the Analogue Joystick. The function will

learn the relationship between the analogue sensor values of the joystick for the whole joystick position range (from

leftmost position to rightmost position) and scale this into an internal resolution in steps of 0.1% for the joystick position

(leftmost to straight ahead and straight ahead to rightmost).

Spool:

This function allows the determination of the spool dead-band based on inputs and demands from the operator. The spool

dead-band is determined (within given inputs) by measuring the duration of moving the spool continuously from left to

right.

The function is intended to be an alternative solution for spool calibration for mass production environments where a large

number of vehicles is produced and a quick automated spool calibration is needed. The function can provide a precise

dead-band calibration of the spool in a relatively short time (depending on the parameter setup) without having an operator

directly involved.

Before starting any auto-calibration, the parameters in the sector “Auto-calibration Config” shall be studied, as these are

important to get the desired setup on the vehicle.

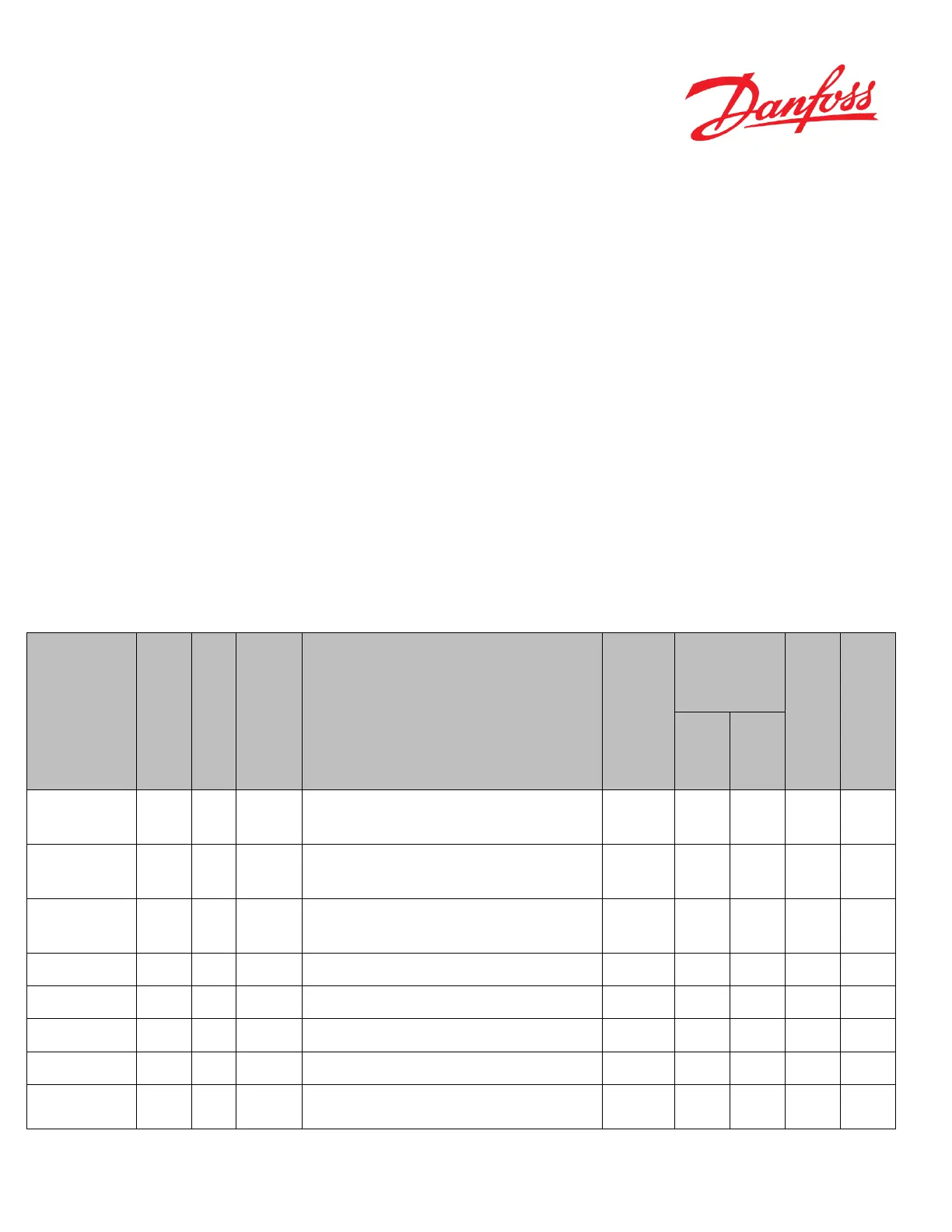

Auto-calibration Config

Name

Description of parameter

Range

Safety critical

parameters ‘S’

calibration - Max

allowable analogue

sensor signal to be

P3791 U16 mVolts

Maximum allowed signal to be captured for neutral position during

Analogue sensor auto-calibration

OEM, Dealer 0 5000 4500

calibration - Min voltage

needed in between the

captured analogue

P3793 U16 mVolts

Determines the minimum voltage needed in between the captured

Analogue sensor voltage (minimum, neutral and maximum), to ensure a

sufficient high analogue signal resolution during Analogue sensor auto-

calibration.

OEM, Dealer 0 2500 0

calibration - Min

allowable analogue

sensor signal to be

P3795 U16 mVolts

Minimum allowed signal to be captured for neutral position during

analogue sensor auto-calibration.

OEM, Dealer 0 5000 500

closed loop dead-band

P3797 U16 x10u Meter

Maximum closed loop dead-band value (for both left- and right-side),

hence the found dead-band values needs to be in between P3799 and

OEM, Dealer 0 300 300

closed loop dead-band

P3799 U16 x10u Meter

Minimum closed loop dead-band value (for both left- and right-side), hence

the found dead-band values needs to be in between P3799 and P3797.

OEM, Dealer 0 300 0

Spool calibration -

Activation timeout

P3801 U8 -

The time window the user has to start the spool auto-calibration (i.e. to

press the “Start Calibration” button) after the steering wheel has been

activated and the motion has stopped again

OEM, Dealer 1 60 20

Spool calibration -

Initial spool position

P3802 U16 x10u Meter

The initial spool position value, the spool auto-calibration function will

start at. The higher set-point, the faster the wheels movement will be.

Recommend: 115 for OSPE/EHi; 200 for EHPS

OEM, Dealer 50 300 125

Spool calibration - +/-

turn range sweep

P3804 U16 dDeg

This is the +/- turn range sweep where the auto-calibration function will

measure the time for when moving the spool from left to right and right to

left.

Resolution: 1 dDeg 1 = 0,1°.

OEM, Dealer 5 400 25

Loading...

Loading...