© Danfoss | August 2018 AQ00000211 | 181

17.6.5.3 Post conditions

After a successful manual spool calibration, the calibration counter and bit inverted copy for spool calibration should be

updated as described below:

• Populate a temporary data sector for “Production/Calibration Flag”. Update the Spool dead-band calibration

counters. Increment P3771 from 0 to 1 and increment bit-wise inverted P3772 from 255 to 254 for the displayed

below,

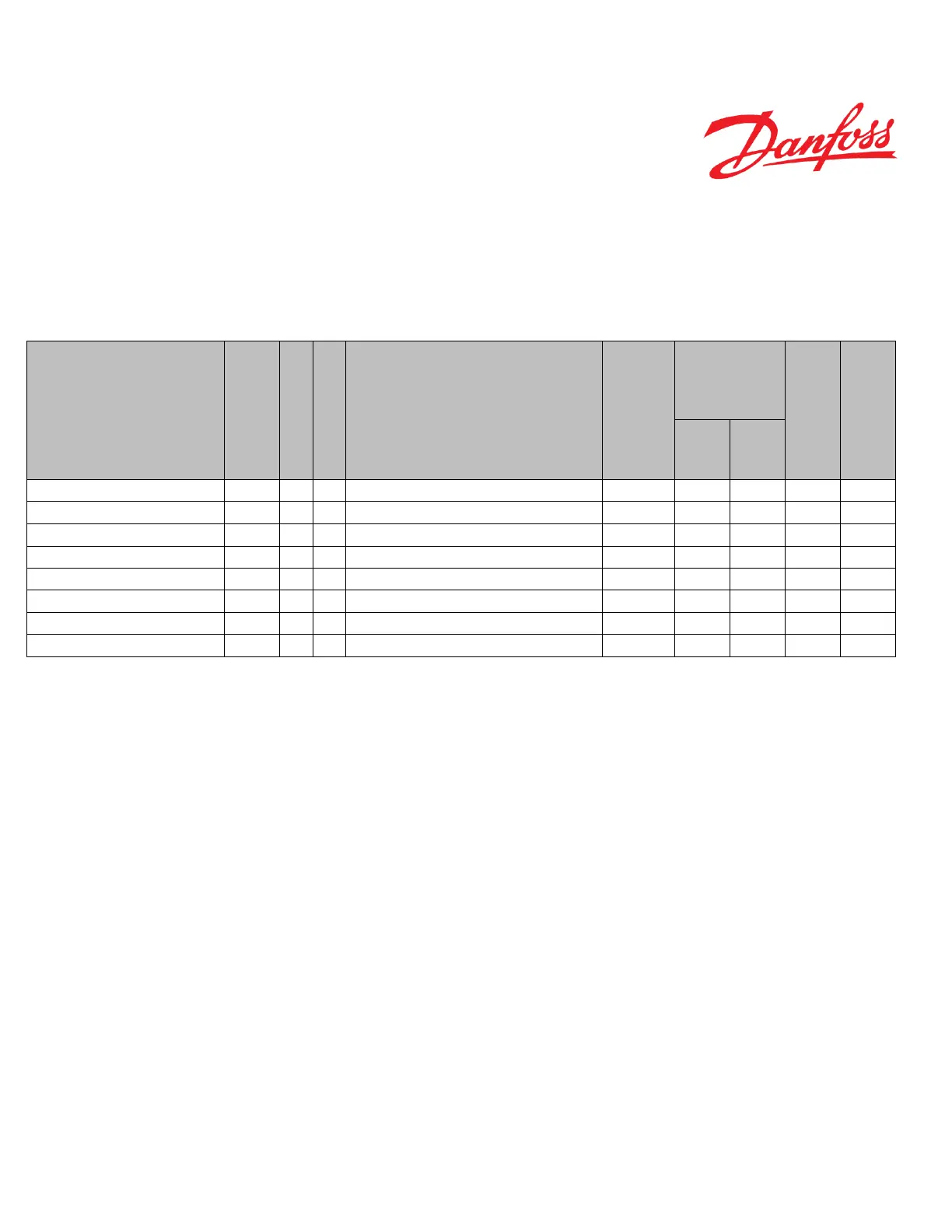

Production/Calibration Flag

Name

Description of parameter

Range

Safety critical

parameters ‘S’

Calibration counter - Spool calibration

P3771 U8 - Calibration counter - Spool calibration OEM 0 255 0

Bit inverted value for "Calibration counter -

Spool calibration"

P3772 U8 - Bit inverted value for "Calibration counter - Spool calibration" OEM 0 255 255

Calibration counter - Analogue WAS

calibration

P3773 U8 - Calibration counter - Analogue WAS OEM 0 255 0

Bit inverted value for "Calibration counter -

Analogue WAS calibration"

P3774 U8 - Bit inverted value for "Calibration counter - Analogue WAS" OEM 0 255 255

Calibration counter - CAN WAS calibration

P3775 U8 - Calibration counter - CAN WAS OEM 0 255 0

Bit inverted value for "Calibration counter -

CAN WAS calibration"

P3776 U8 - Bit inverted value for "Calibration counter - CAN WAS" OEM 0 255 255

Calibration counter - Analogue joystick P3777 U8 - Analogue sensor based Joystick calibration counter OEM 0 255 0

Bit inverted value for "Calibration counter -

Analogue joystick"

P3778 U8 -

Bit inverted value for Analogue sensor based Joystick

calibration counter

OEM 0 255 255

Table 91

• Calculate the sector CRC as CRC-16-CCITT (P3771…P3778) and store (word) at the CRC/Checksum address

(P3789). For example of how to calculate sector CRC, please see paragraph 17.5.2

• Write data sector “Production/Calibration Flag” to the MAIN-controller

Loading...

Loading...