© Danfoss | August 2018 AQ00000211 | 67

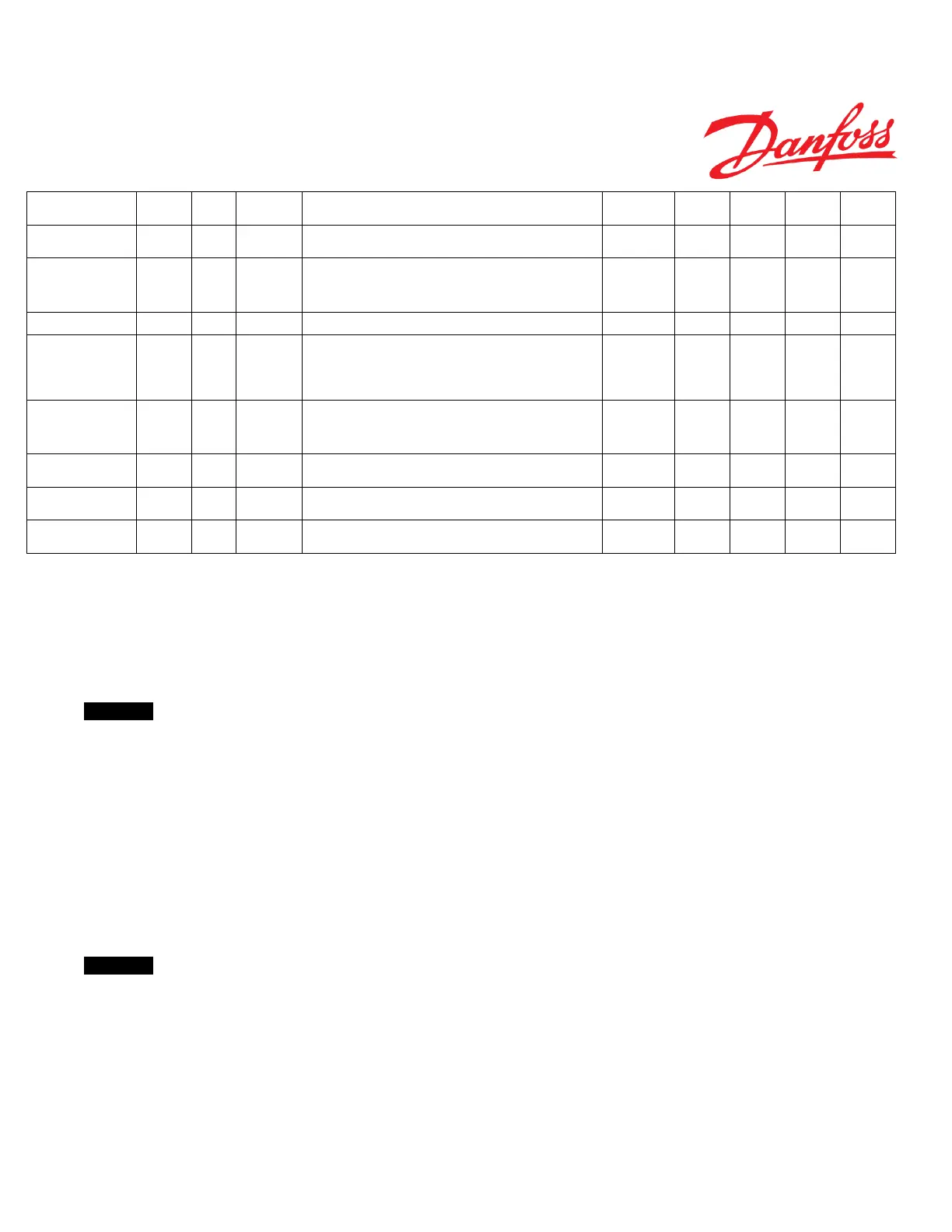

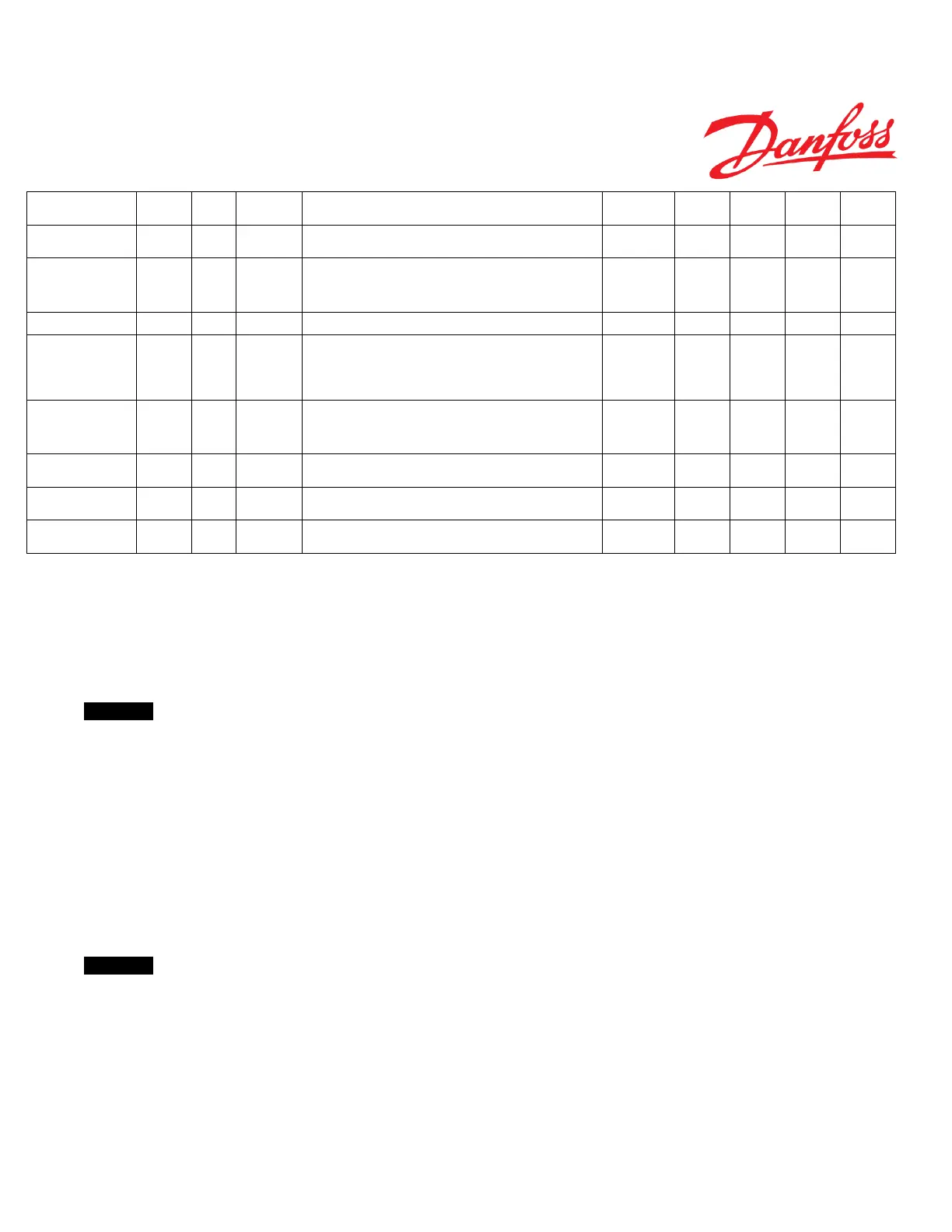

time for acceptable CL

P3806 U16 x100msec

P3806 and P3808 indicate the target sweep time for the spool calibration

function, to find an acceptable closed loop dead-band edge. That maximum

given time is defined by P3806

OEM, Dealer 10 600 110

time for acceptable CL

P3808 U16 x100msec

P3806 and P3808 indicate the target sweep time for the spool calibration

function, to find an acceptable closed loop dead-band edge. The minimum

given time is defined by P3808

OEM, Dealer 10 600 60

Spool calibration -

Vector sample size

P3810 U8 -

In most cases, to find an acceptable closed loop dead-band edge within a

given time frame requires more attempts (to ensure consistency in the

captured/found values).

P3810 defines the vector size for how many attempts (for left- and right-

side dead-band edge, respectively) should be considered

OEM, Dealer 1 10 7

Spool calibration - Min

valid samples

P3811 U8 -

P3811 defines how many of the attempts (defined by P3810) that need to

be equal to get a successful spool calibration.

OEM, Dealer 1 10 5

Spool calibration - +/-

turn range sweep add-on

P3812 U16 dDeg

This indicates the additional +/- turn range, which will be added to the

value in P3804. The additional turn range movement is required to obtain a

stable spool position and stable wheel movement of the vehicle. The

wheels will move in between this +/- turn range, but time will only be

measured in between the +/- turn range specified by P3804.

Resolution: 1 dDeg 1 = 0,1°.

OEM, Dealer 5 400 25

Spool calibration -

Spool set-point

increase/decrease step

P3814 U8 %

When the auto-calibration function has determined that the last attempt was

too slow or to fast (hence, within the time frame specified by P3806 and

P3808), it will:

• Too slow: add the value specified by P3814 to last set-point value.

• Too fast: subtract the value specified by P3814 to last set-point value

OEM, Dealer 1 25 10

WAS signal to be

P3881 U16 mVolts

Maximum allowed signal to be captured for neutral position during CAN

WAS auto-calibration

OEM, Dealer 0 5000 4500

between the captured

P3883 U16 mVolts

Determines the minimum voltage needed in between the captured CAN

WAS voltage (minimum, neutral and maximum), to ensure a sufficient

high wheel angle resolution during CAN WAS auto-calibration.

OEM, Dealer 0 2500 0

WAS signal to be

P3885 U16 mVolts

Minimum allowed signal to be captured for neutral position during CAN

WAS auto-calibration

OEM, Dealer 0 5000 500

Table 30

9.4.1.1 Auto-calibration parameter plausibility check

P3791, P3795:

Maximum and minimum allowed analogue sensor signal to be captured for analogue sensor (WAS or Joystick) neutral

position. This is applicable for primary and redundant analogue sensor.

• P3795 < “captured neutral analogue sensor signal value” < P3791.

Important

The analogue sensor auto-calibration routine will return an error message if the straight heading falls outside the range.

Use these parameters to control the straight heading range.

P3793:

Determines the minimum voltage needed in between the captured analogue sensor values (minimum, neutral and

maximum), to ensure a sufficiently high analogue sensor resolution. The algorithm will determine if left or right has the

highest value. This is applicable for primary and redundant analogue sensor.

• “Captured rightmost analogue sensor values” - “Captured neutral analogue sensor values” ≥ P3793 and

“Captured neutral analogue sensor values” - “Captured leftmost analogue sensor values” ≥ P3793.

or

• “Captured leftmost analogue sensor values” - “Captured neutral analogue sensor values” ≥ P3793 and

“Captured neutral analogue sensor values” - “Captured rightmost analogue sensor values” ≥ P3793)

Important

The WAS or Joystick auto-calibration routine will return an error message if detected analogue sensor calibration values

result in a too small working range.

P3797, P3799:

Loading...

Loading...