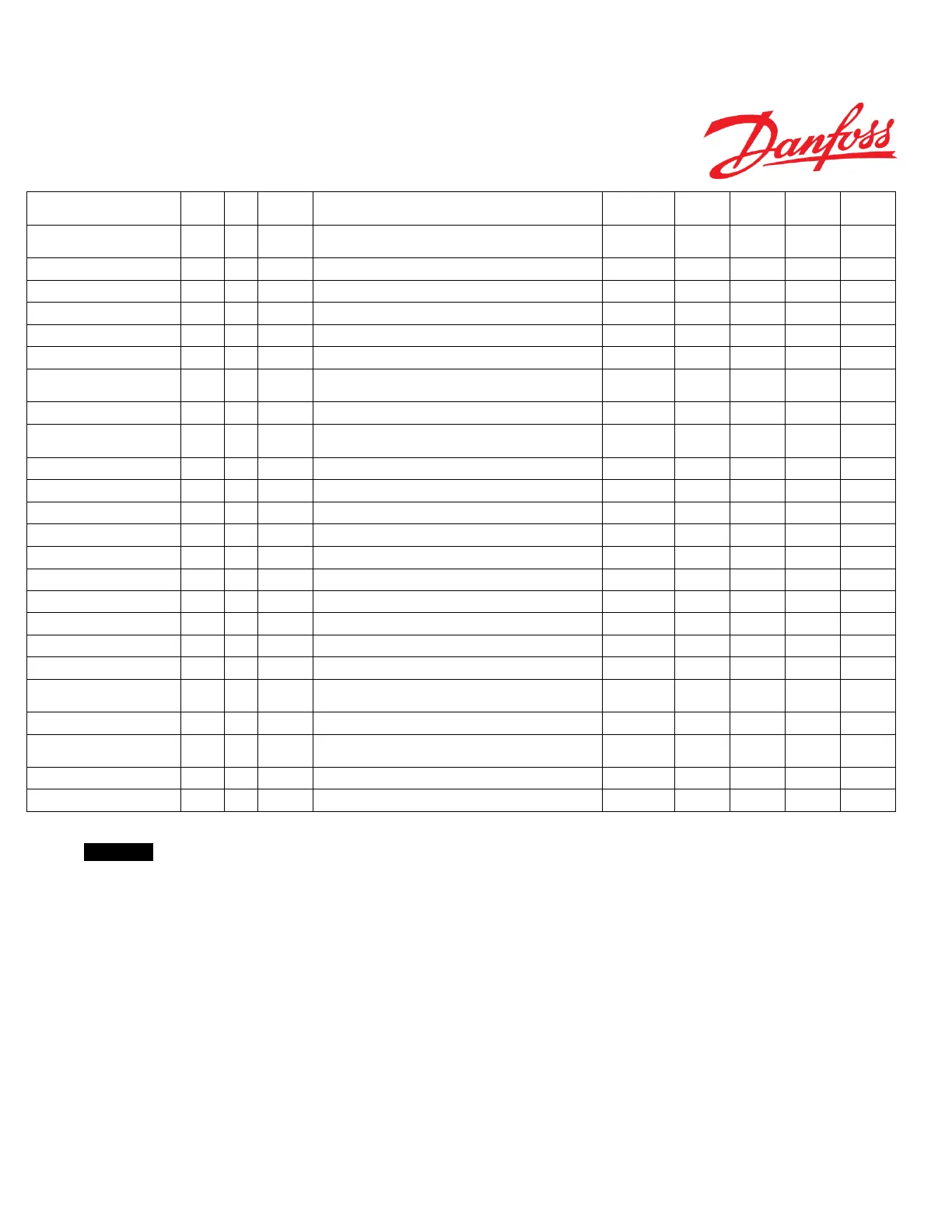

© Danfoss | August 2018 AQ00000211 | 161

STW 5 - No of turns @ Point B P3556 U16 -

Program5 - Number of steering wheel turns lock to lock at the vehicle

speed of "STW 5 - Vehicle speed @ Point B"

Resolution = 0.01; 1turn = 100

OEM 10 800 800 S

STW 5 - No of turns @ Point C P3558 U16 -

Program5 - Number of steering wheel turns lock to lock at the vehicle

speed of "STW 5 - Vehicle speed @ Point C"

Resolution = 0.01; 1turn = 100

OEM 10 800 800 S

STW 5 - Vehicle speed @ Point B P3560 U8 km/h

Program5 - Vehicle speed at which lock to lock steering wheel turns =

"STW 5 - No of turns @ Point B”

OEM 1 100 5 S

STW 5 - Vehicle speed @ Point C P3561 U8 km/h

Program5: Vehicle speed at which lock to lock steering wheel turns =

"STW 5 - No of turns @ Point C”

OEM 1 100 10 S

STW soft-stop wheel angle region

start

P3562 U16 IR

Defines the wheel angle region start, from the max possible wheel angle

towards 0, in which the soft stop has to be applied

OEM 0 1000 400

STW soft-stop max flow @ cylinder

end-stop

P3564 U16 IR Oil flow to deliver at the max possible wheel angle OEM 0 1000 0

STW soft-stop wheel angle region

end

P3566 U16 IR

Defines the wheel angle region end, from the max possible wheel angle

towards 0, in which the soft stop region shall end

OEM 0 1000 0

STW anti-drift - Max steering wheel

drift correction

P3568 U8 Deg

The difference between the observed and ideal STW steering angle at

which and above which the max. EFU correction ("STW Anti-drift -

Max flow correction") shall be applied.

OEM 1 160 20

STW anti-drift - Max flow

correction in percentage of full flow

P3569 U8 % Max flow correction which can be requested by the EFU algorithm OEM 0 100 15

Backlash region P3570 U8 dDeg

Backlash limit to use in the backlash filter in the steering wheel control

algorithm

Resolution: 1dDeg = 0.1Deg

OEM 0 200 5

STW anti-jerk function P3571 U8 -

Defines the type of the anti-jerk functionality to

use 0 for Anti Jerk type NONE and 1 for Anti Jerk type 1

OEM 0 1 0

STW relative set-point change, out

from spool neutral position

P3572 U8 %

Relative set-point change allowed to apply when ramping the spool

position set-point out, i.e. further out from the spool neutral position [%]

OEM 0 100 5

STW relative set-point change, in

towards spool neutral position

P3573 U8 %

Relative set-point change allowed to apply when ramping the spool

position set-point in, i.e. towards the spool neutral position [%]

OEM 0 100 5

STW absolute set-point change, out

from spool neutral position

P3574 U16 IR

Set-point change allowed to apply when ramping the spool position set-

point out, i.e. further out from the spool neutral position

OEM 1 1000 15

STW absolute set-point change, in

towards spool neutral position

P3576 U16 IR

Set-point change allowed to apply when ramping the spool position set-

point in, i.e. towards the spool neutral position

OEM 1 1000 10

STW anti-jerk cross-over start point P3578 U16 IR STW Anti-jerk Cross-over start OEM 0 1000 10

STW anti-jerk cross-over stop point P3580 U16 IR STW Anti-jerk Cross-over stop OEM 0 1000 10

STW anti-jerk low pass filter cut-off

frequency

P3582 U8 dHz

STW Anti-jerk low pass filter cut-off frequency

Resolution: 1 dHz = 0.1 Hz

OEM 5 200 100

STW in use - Velocity threshold P3583 U8 dRpm Steering wheel velocity threshold OEM 1 100 5 S

STW in use - Angle threshold P3584 U8 Deg

Steering wheel position change threshold, from last detected position at

0 RPM

OEM 0 45 10 S

Native wheel angle range for

steering wheel programs

P3585 U8 deg

Lock to lock wheel angle range

Used internally to maintain the steering sensitivity/aggressiveness when

physical max wheel angle endpoints are changed

OEM 0 255 255 S

IMD - EH-Steering disengage

confidence limit

P3586 U8 x10mSec

Timeout value to declare steering movements to be active if EH-Spool

stays within the limit specified by P3090.

OEM 0 255 30

IMD - EH-Spool in neutral

confidence limit

U8 x10mSec

If EH-Spool stays within the threshold specified by P3090 for the

timeout value specified by P3590, IMD overrules EH-Steering

algorithms and takes over spool control to evaluate spool position.

OEM 0 255 15

IMD - Dynamic SVC integral limit

U8 - Dynamic SVC integral limit to use while EH-Spool is close to neutral OEM 0 255 10

IMD - Dynamic SVC integral gain

U16 - Dynamic SVC integral gain to use while EH-Spool is close to neutral. OEM 0 65535 225

Table 74

Important

For the STW sector some rules apply to the parameter settings of the vehicle speed dependent functions. See list of rules

in section 10.