FC 300 Design Guide

How to Program

Function:

This parameter is only active in adjustable freq u ency

drives with an integral dynamic brake.

The monitoring limit is a p roduct of the maximum

duty cycle (120 sec.) and the maximum

power of the brake resistor at that duty cycle.

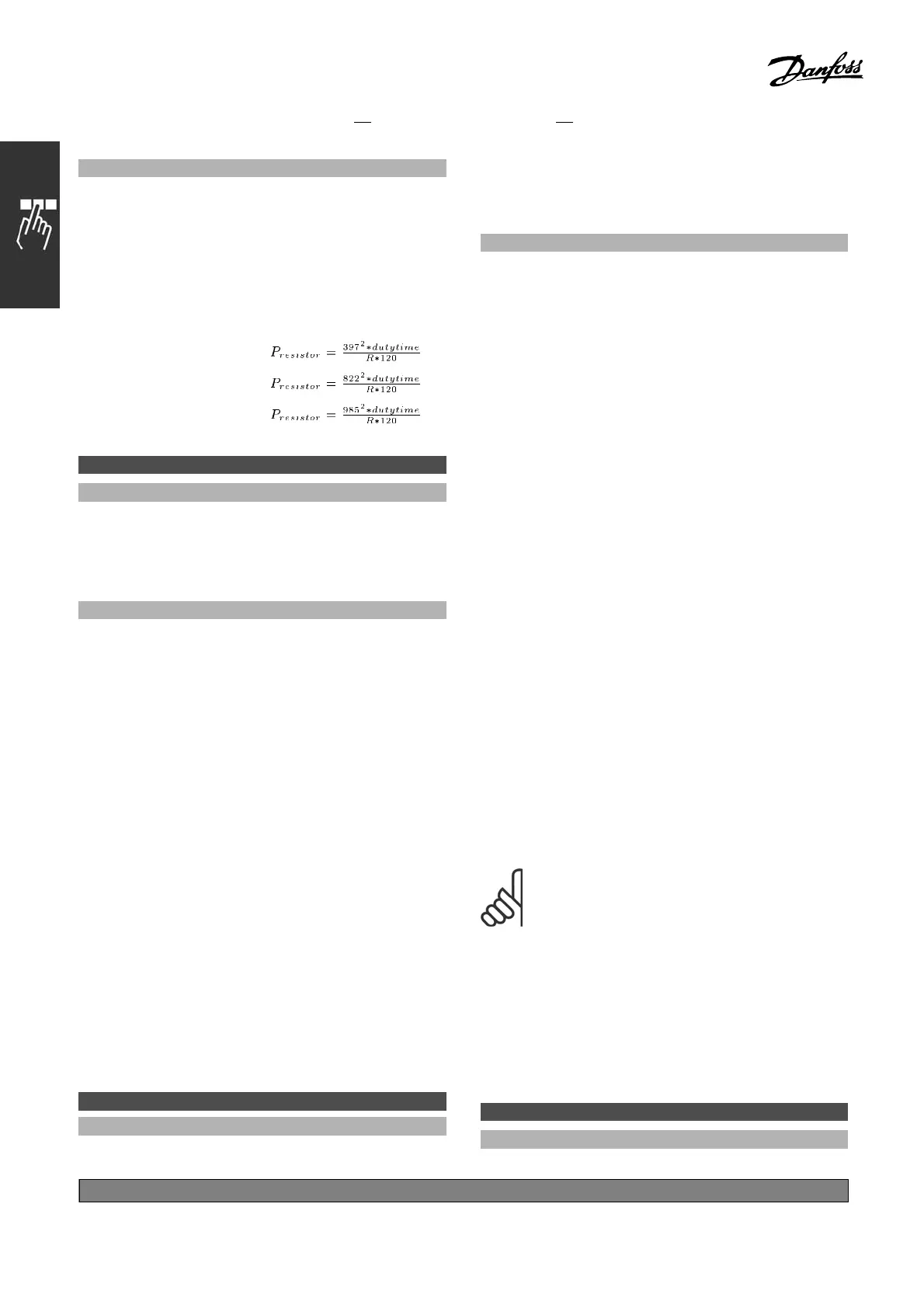

See the formula below.

For 200 - 240 V units:

For 380 - 500 V units

For 575 - 600 V units

2-13 Brake Power Monitoring

Option:

*

Off [0]

Warning [1]

Trip [2]

Warning a nd Trip [3]

Function:

This parameter i

s only active in adjustable freq uency

drives with an integral dynamic brake.

Allows monitoring of the power to the brake

resistor. The power is calculated on the basis of

the resist

or ohm value (par. 2-11), the DC link

voltage, and the resistor duty time. If the power

transmitted over 120 s exceeds 100% of the

monito

ring limit (par. 2-12) and Warning [1] is

selected, a warning appears on the display.

The warning disappears if the power goes below

80%.

If the calculated power exceeds 100% of

the monitoring limit and Trip [2] is selected in par.

2-13 Power Monitoring, the adjusta ble frequency

dr

ive trips and displays an alarm.

If power monitoring is set to Off [0] or Warning

[1], the brake function rema ins active, even if the

m

onitoring limit is exceeded. This may lead to

thermal overload of the resistor. It is also possible

to have a warning via a relay/digital outputs.

The mea suring accuracy of the power monitoring

depends on the accuracy of the resistance of

the resistor (better than ± 20% ).

2-15 Brake Check

Option:

*

Off [0]

Warning [1]

Trip [2]

Trip and Stop [3]

Function:

This parameter is only active in adjustable frequency

drives w ith an integral dynamic brake.

Enables the integration of a test and m onitor

function, which displays a warning or an alarm. On

power-up, the functions is tested for disconnection

of the brake resistor. The test is carried out during

braking. Testing for disconnection of the IGBT,

however, is carried out when there is no braking.

A warning or trip disconnects the brake function.

The testing sequence is as follows:

1. The DC link ripple amplitude is measured

for 300 ms without braking.

2. The DC link r ipple am plitude is measured for

300 ms with the brake turned on.

3. If the DC link ripple amplitude while braking

is lower tha n the DC link ripple amplitude

before braking + 1 %. Brake check failed,

return a warning or ala rm.

4. If the DC link ripple amplitude while braking

is higher than the DC link ripple amplitude

before braking + 1 %. B rake check OK

Select Off [0]. This function still m onitors whether

the brake resistor and the brake IGBT short circuit

during operation. If so, a warning appears. Sel

ect

Warning [1] to monitor the brake resistor and brake

IGBT for to short circuiting. During power-up,

disconnection of the brake resistor is chec

ked.

NOTE

Remove a warning arisen in connection

with Off [0] or Warning [1] by cycling

the mains supply. The fault must be

corrected first. Wit h Off [0] or Warning [1 ], the

adjustable frequency drive keeps running even

if a fault is located. In the ca

se of Trip [2], the

adjustable frequency drive cuts out while displaying

an alarm (trip locked). This happens if the brake

resistor is short circuite

d, is disconnected, or if

the brake IGBT is short circuited.

2-17 Over-voltage Control

Option:

*

Disabled [0]

*

default setting ()display text []value for use in communication via serial communication port

152

MG.33.B

3.22 - VLT is a registered Danfoss trademark

Loading...

Loading...