FC 300 Design Guide

Introduction to FC 300

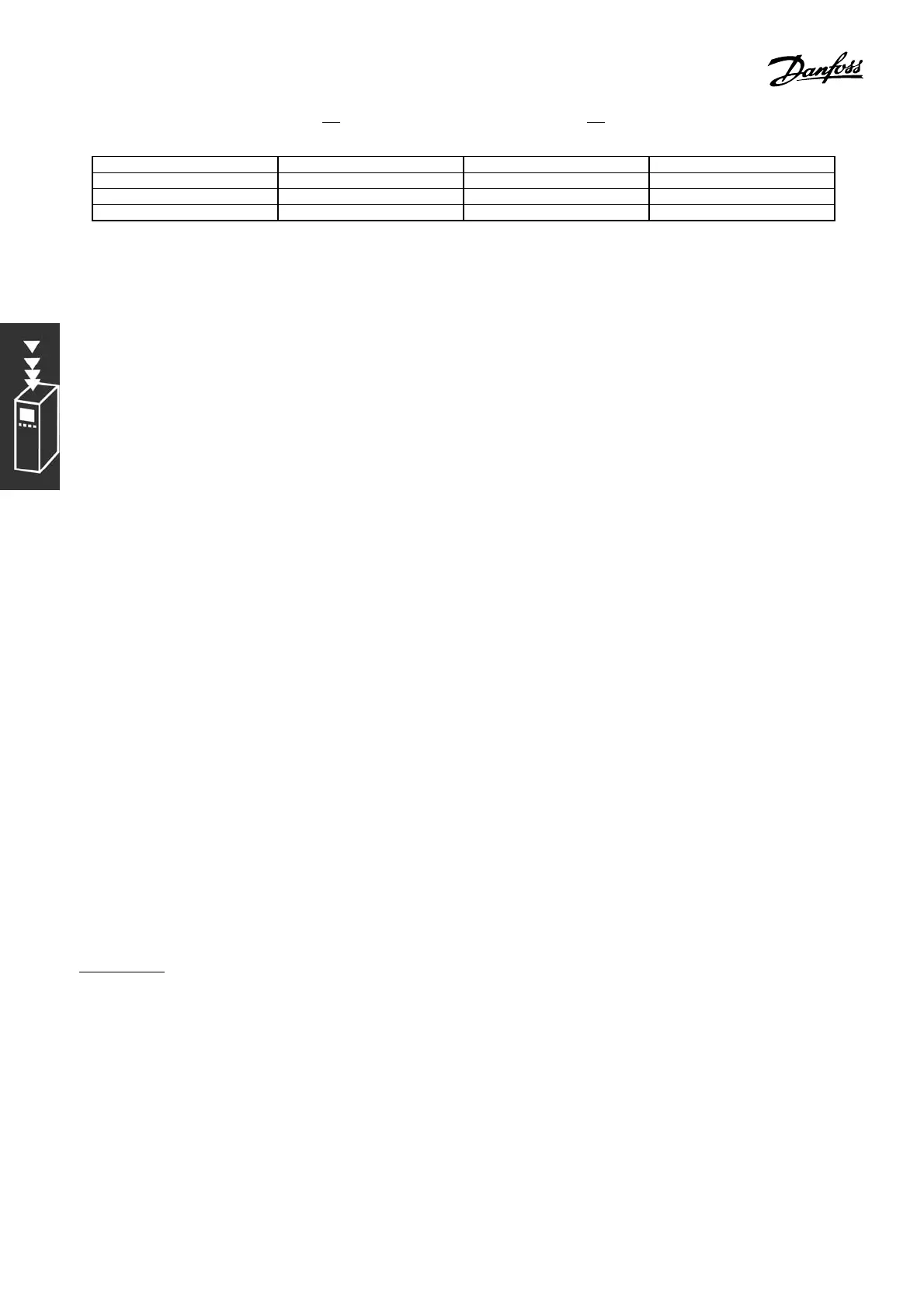

Type of Control Proportional Gain Integral Time Differentiation Time

PI-control 0.45 * K

u

0.833 * P

u

-

PID tight control 0.6 * K

u

0.5 * P

u

0.125 * P

u

PID some overshoot 0.33 * K

u

0.5 * P

u

0.33 * P

u

Table 1: Ziegler Nichols tuning for regulator, base

d on a stabili ty boundary.

Experience has shown that the control setting according to the Ziegler Nichols rule provides

a g ood closed-loop response for many systems. The process o perator can perform final

tuning of the control iteratively to yield satisfactory control.

Step-by-step:

Step 1: Select only Proportional Control, meaning that the Integral time is selected to the

maximum value, while the differentiation time is selected to zero.

Step 2: Increase the value of the proportional gain until the point of inst ability is rea ched

(sustained oscillations) and the critical value of gain, K

u

, is reached.

Step 3: Measure the period of oscillation to obtain the critica l time constant, P

u

.

Step 4: Use the table above to calculate the necessary PID control parameters.

" Internal Curren t Regulator

Theadjustablefrequencydrivefeaturesanintegral current limit regulator w hich is activated when the

motor current, and thus the torque, is higher than the torque limits set in par. 4-16 and 4-17.

When the adjustable frequency drive is at the current limit during motor operation or regenerative

operation, the adjustable frequency drive will try to g et bel ow the preset torque limits as

quickly as possible without losing control of the motor.

While the current regulator is active, the adjustable frequency drive c an only be stopped by me ans of

a digital terminal if set to Coast, inverse [2] or Coa st and Reset, inverse [3]. Other signals on terminals

18-33 will not be active until the adjustable frequency drive is no longer near the current limit.

" Programming of Torque Limit and Stop

In applications with an external electrome chanical brake, such as hoisting applications,

it is possible to stop the adjustable frequency d rive via a "standard" stop command and

simultaneously activate the external electromechanical brake.

The examp le given below illustrates the programming of adjustable fre quency drive connections.

The exte rnal brake can be connected to relay 1 or 2, see paragraph Control of M echanica l

Brake. Program terminal 27 to Coast, inverse [2] or Coast and Reset, inverse [3], and

program te rminal 29 to Torque limit & stop [27].

D

escription:

If a stop command is active via terminal 18 and the adjustable frequency drive i s not

at the torque limit, the motor ramps down to 0 Hz.

If the a djustable freq u ency drive is at the torque limit and a stop command is activated, terminal 42

Output (programmed to Torque limit and stop [27]) is activated. The signal to terminal 27 l changes

from "logic 1" to "logic 0", and the motor starts to coast, thereby ensuring that the hoist stops even

if the drive itself cannot handle the required torque (i.e. due to excessive overload).

42

MG.33.B3.22 - VLT is a registered Danfoss trademark

Loading...

Loading...