EPSON LX-300+II/300+II RTP/1170II Revision D

Maintenance Maintenance 93

6.1 Maintenance

Appropriate maintenance is necessary to keep the printer in the best condition and prevent

troubles.

6.1.1 Cleaning

Use a neutral detergent or diluted alcohol to clean the exterior surfaces. Vacuum dust or

small pieces of paper inside the printer.

6.1.2 Lubrication

The lubrication points of LX-300+II/LX-1170II are as shown in the following table. Refer

to the table for the type and the amount of oil to be used for each point. Oil and grease have

a great affect on the performance of the product, especially on the durability and the

performance at the lower temperature. EPSON determines what kind of and how much of

oil to be applied based on the various information and analysis.

NOTE: Lubrication must be applied during the re-assembly process.

For lubrication points, refer to the following figures.

Never use thinner, trichloroethylene, or ketone solvent, as it

may deform or deteriorate the plastic parts or rubber parts.

Use the specified amount of the specified oil.

When using compressed air products, such as air duster, for

cleaning during repair and maintenance, the use of such

products containing flammable gas is prohibited.

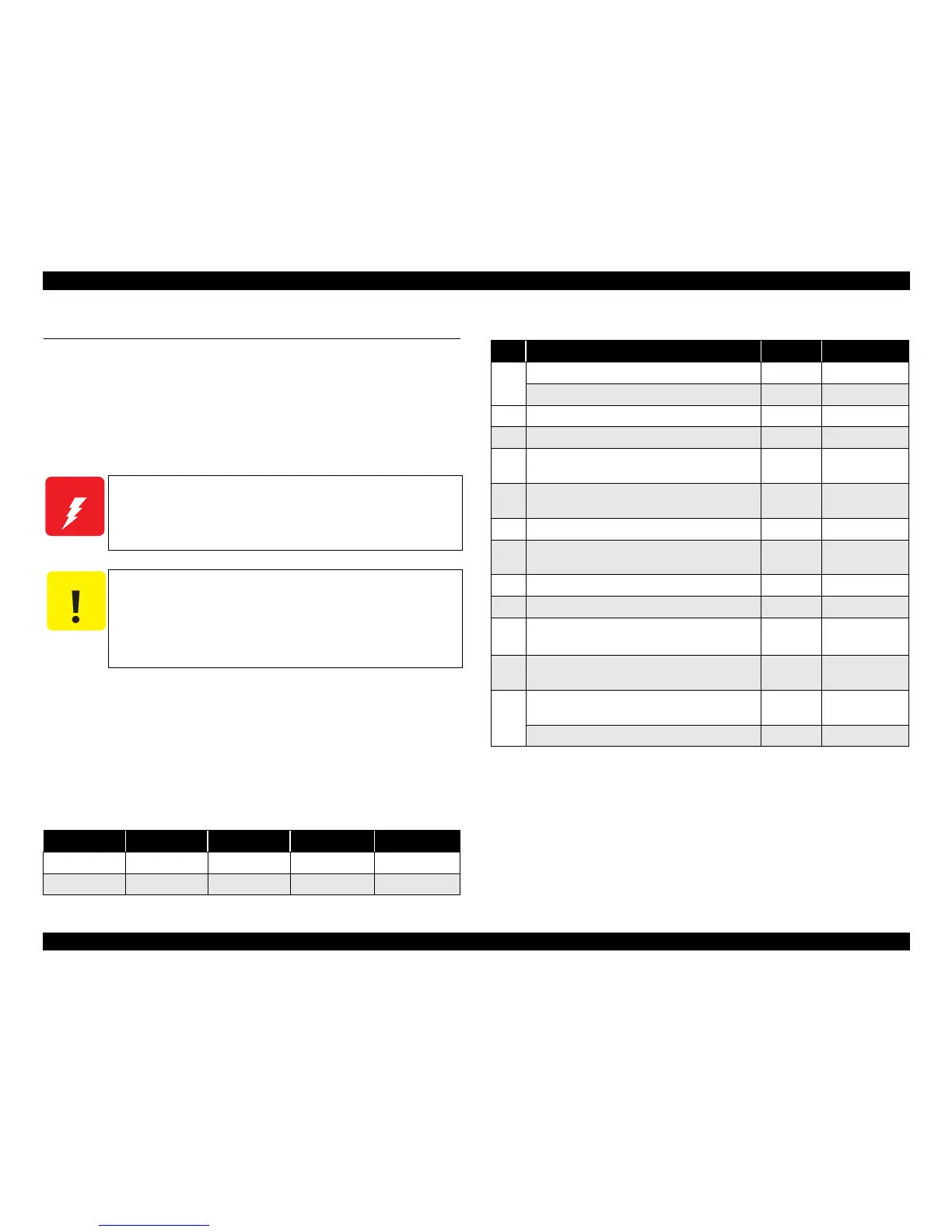

Table 6-1. Lubricants

Type Name Quantity Availability Part No.

Grease G-26 40g EPSON B702600001

Oil O-2 40cc EPSON B710200001

Table 6-2. Lubrication Points

Fig. Lubrication Points Lubricant Quantity

6-1

3 shafts and 1 boss of the left frame G-26 1/2 grain of rice

Shaft of RD ratchet G-26 1 grain of rice

6-2 Teeth of Gears at the left frame G-26 1/2 grain of rice

6-3 3 places on the 3 shafts of the right frame G-26 1 grain of rice

6-4

2 places on inside of cam at slope surface of the

release lever

G-26 1 grain of rice

6-5

Shaft of the PF roller drive and the rear driven PF

roller.

G-26 1/2 grain of rice

6-6 Paper guide from the back side at 4 places G-26 1 grain of rice

6-7

Hole of the right tractor assy frame faces to the

tractor assy guide shaft and the left TR frame.

G-26 1/2 grain of rice

6-8 Oil pad O-2 0.28-0.32cc

6-9 Touching parts of the 2 sides of the base frame. G-26 40 mm x 2 places

6-10

2 touching positions with the CR motor assembly

from the inside of the base frame.

G-26

1/2 grain of rice

x 2

6-11

Installing shaft of the combination gear, 17.5, 27 of

the right frame.

G-26 1/2 grain of rice

6-12

Touching position of the grounding platen spring

with platen shaft.

G-26 1 grain of rice

Spur gear 34 G-26 10 mm

Loading...

Loading...