MAINTENANCE

7-6

PERIODIC REPLACEMENT OF PARTS

To ensure safe and long trouble free operation, be sure to

conduct periodic inspections of the machine. In addition,

the parts as listed below are directly related to safety op-

eration so that they are recommended to be periodically

replaced. These part material properties will change due to

aging, or repeated operation may cause deterioration, wear,

and/or fatigue of these parts, possibly resulting in serious

safety/fire hazards. It is very difficult to gauge the remaining

service lifetime of these parts simply by visual inspection

alone. For this reason, replace these parts at the intervals

shown in the table below. If any of these parts are found to

be defective by inspection, immediately replace it regard-

less of the recommended intervals.

Consult your nearest Hitachi dealer for correct replace-

ment.

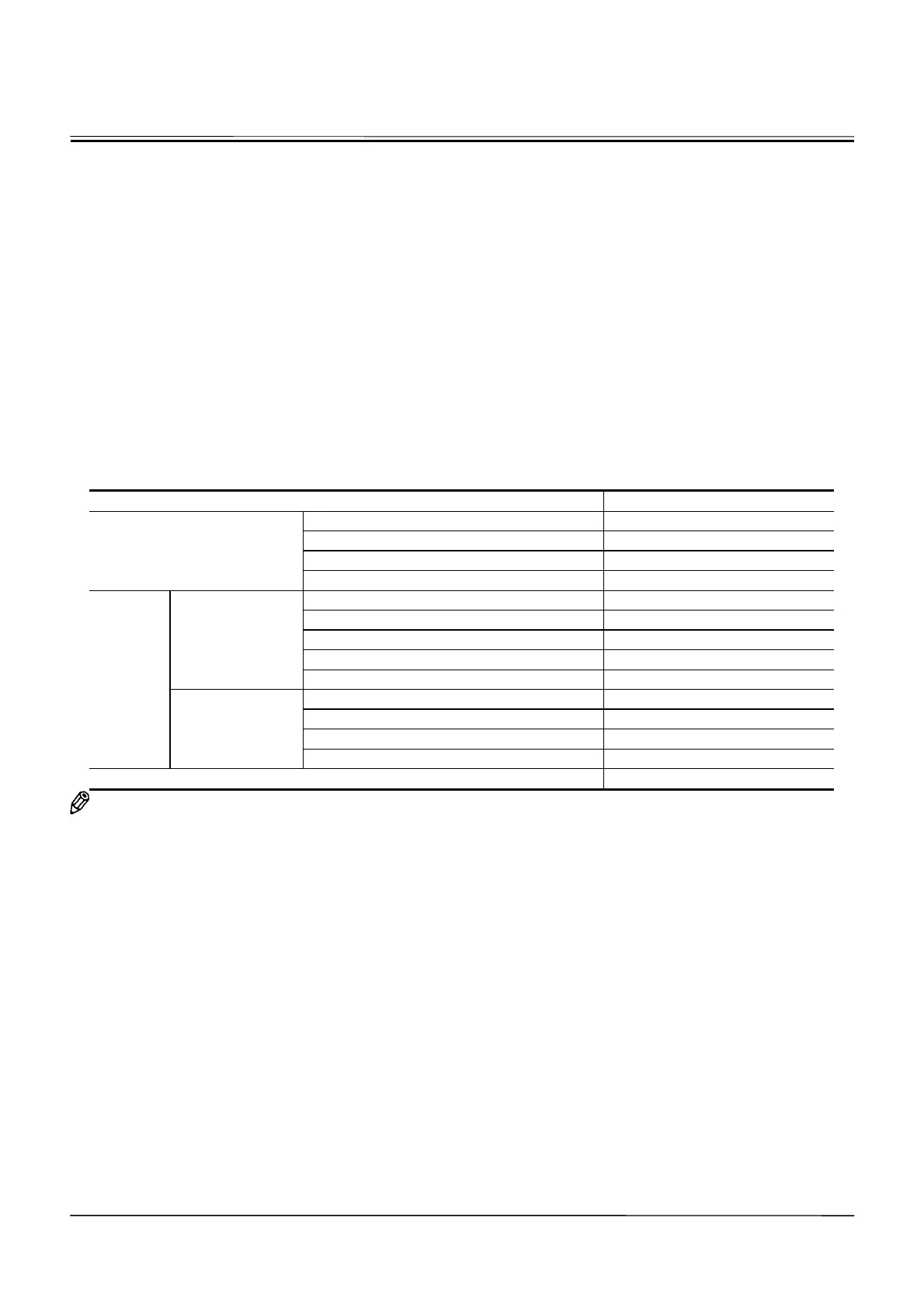

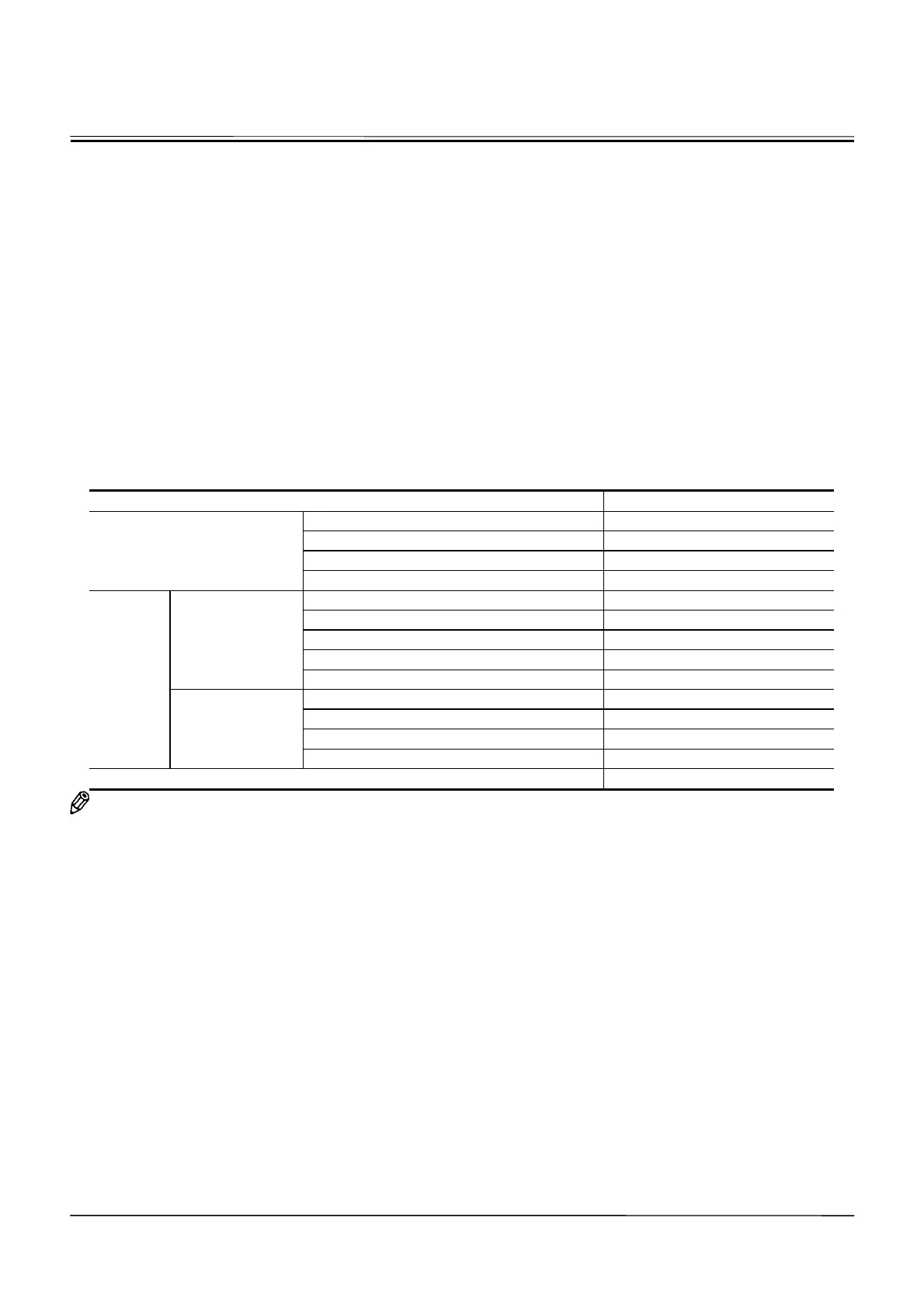

Periodic Replacement Parts Replacement Interval

Fuel hose (Fuel tank to filter) Every 2 years or 4000 hours

Fuel hose (Fuel tank to injection pump) Every 2 years or 4000 hours

Engine rubber vibration insulator Every 5 years or 3000 hours

Engine

Pump coupling Every 5 years or 3000 hours

Pump suction hose Every 2 years or 4000 hours

Pump delivery hose Every 2 years or 4000 hours

Swing hose Every 2 years or 4000 hours

Auxiliary hose Every 2 years or 4000 hours

Base Machine

Oil cooler hose (C/V to oil cooler) Every 2 years or 4000 hours

Boom cylinder line hose Every 2 years or 4000 hours

Arm cylinder line hose Every 2 years or 4000 hours

Bucket cylinder line hose Every 2 years or 4000 hours

Hydraulic

System

Front Attachment

Pilot hose Every 2 years or 4000 hours

Seat Belt Every 3 years

NOTE: When replacing a hose, be sure to replace seals, such as O-rings and gaskets, along with the hose.

Loading...

Loading...