MAINTENANCE

7-60

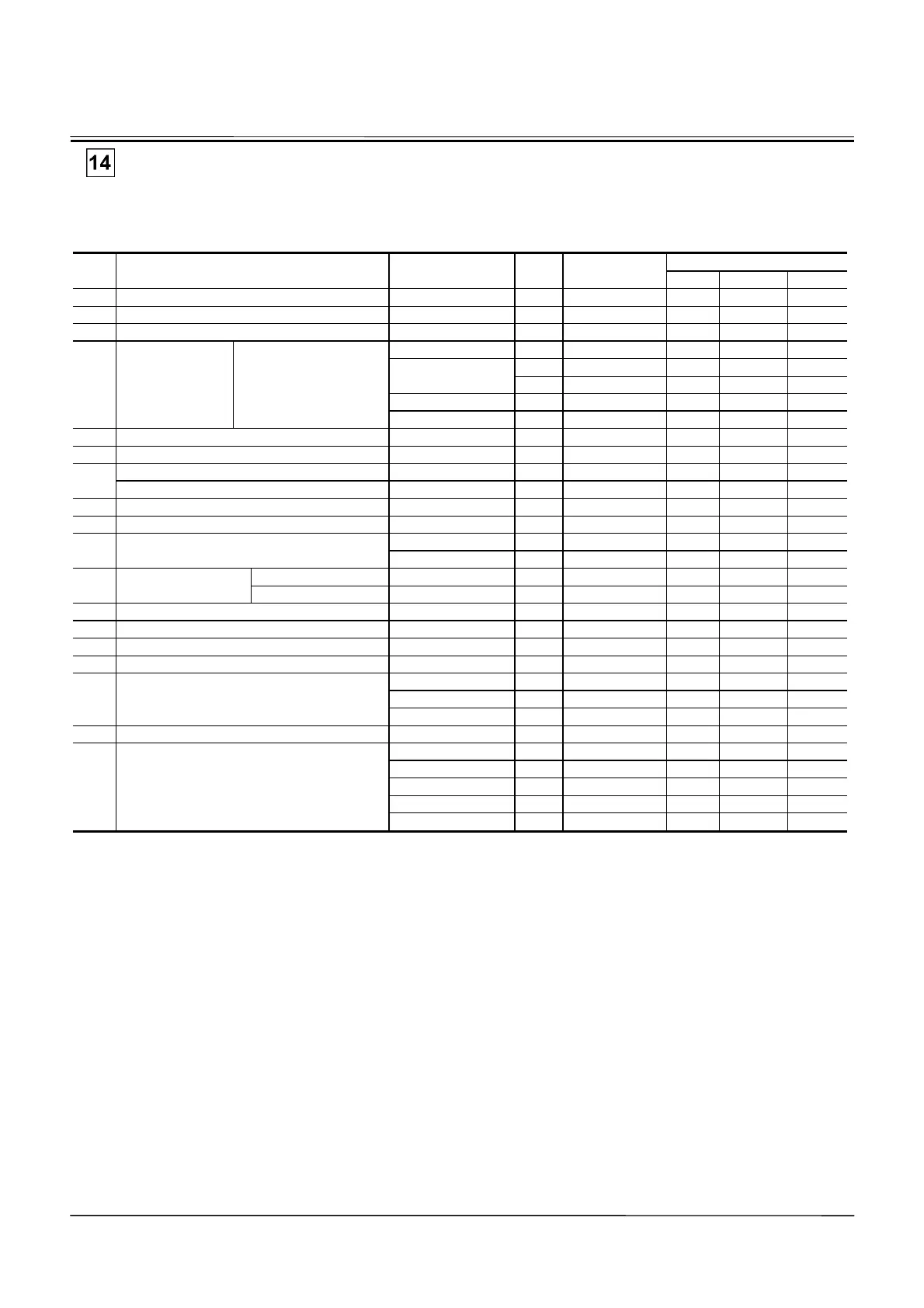

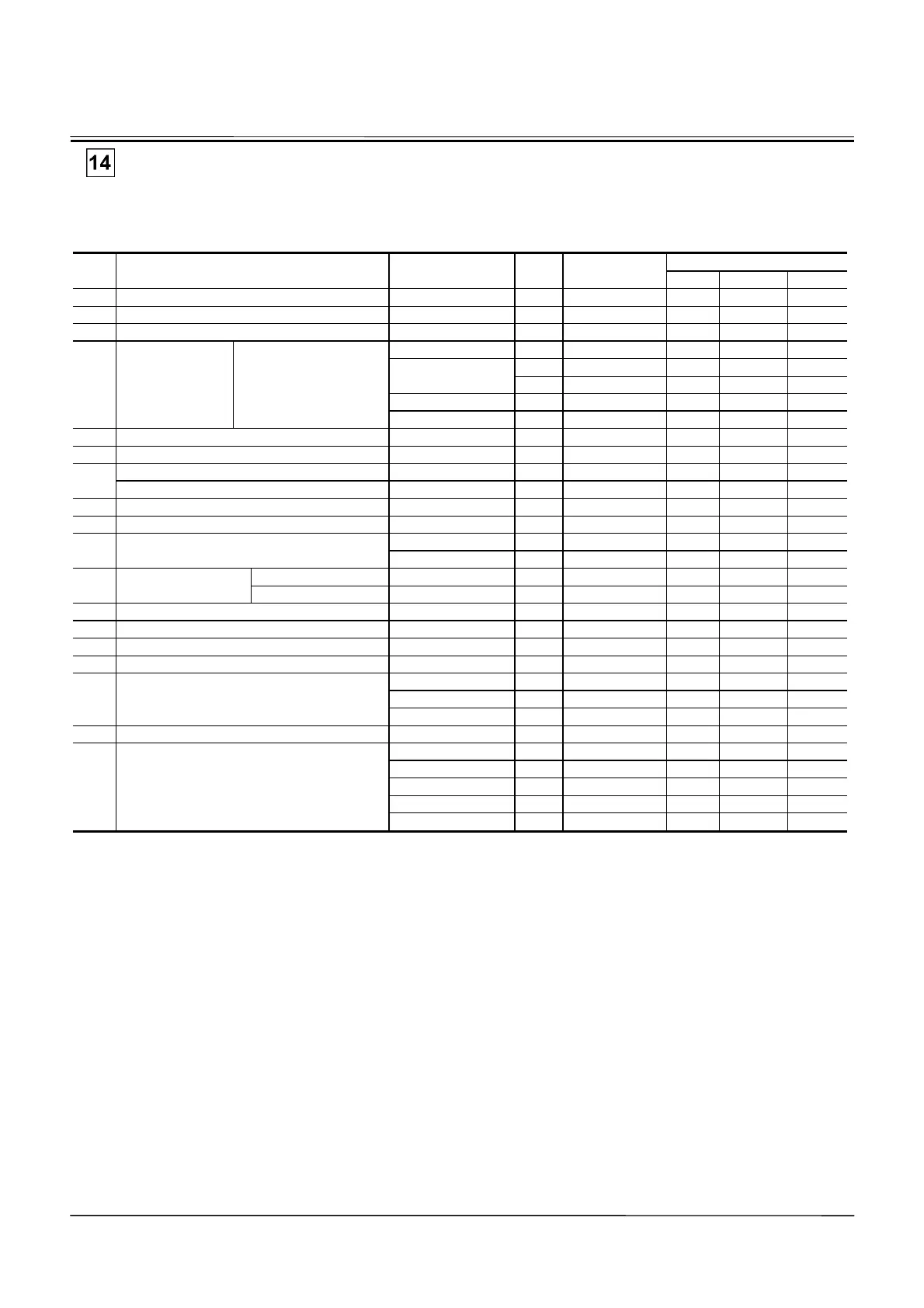

Check Tightening Torque of Bolts and Nuts

--- every 250 hours (first time after 50 hours)

Tighten or retighten all bolts and nuts to the torque values shown in the Table below. In addition, check bolts and

nuts for looseness and omission. if any are loose or missing, be sure to retighten or supply new parts. Check

tightness after the first 50 hours then every 250 hours.

Torque

No. Descriptions

Bolt Dia.

mm

Q’ty

Wrench Size

mm

N⋅m (kgf⋅m) (lbf⋅ft)

1. Engine cushion rubber mounting bolt 12 4 19 88 (9) (65)

2. Engine bracket mounting bolt (Front) 10 8 17 49 (5) (36)

3. Hydraulic oil tank mounting bolt 12 4 19 88 (9) (65)

7/16-20UNF 17 24.5 (2.5) (18)

19 29.5 (3) (22)

9/16-18UNF

22 39 (4) (29)

3/4-16UNF 27 93 (9.5) (69)

4.

Union joints

for hydraulic

hoses and

pipes

Metal face seal

fitting for hydraulic

hoses and piping

1-1/16-12UNF 36 175 (18) (129)

5. Pump mounting bolt 12 2 19 88 (9) (65)

6. Pump cover mounting bolt 10 8 17 49 (5) (36)

Control valve mounting bolt 10 4 17 49 (5) (36)

7.

Control valve base mounting bolt 10 4 17 49 (5) (36)

8. Swing device mounting bolt 12 4 19 88 (9) (65)

9. Battery mounting nut 6 4 10 5 (0.5) (3.5)

10 3 17 49 (5) (36)

10. Canopy mounting bolt

12 4 19 88 (9) (65)

Upperstructure 10 16 17 49 (5) (36)

11.

Swing bearing

mounting bolt

Undercarriage 10 18 17 49 (5) (36)

12. Travel device mounting bolt 10 16 8 (Socket) 64 (6.5) (47)

13. Sprocket mounting bolt 10 18 8 (Socket) 64 (6.5) (47)

14. Steel crawler guide mounting bolt 10 8 17 49 (5) (36)

15. Lower roller mounting bolt 14 12 22 177 (18) (130)

6 10 5 (0.5) (3.5)

8 13 9.8 (1) (7)

16. Cover mounting bolt

10 17 49 (5) (36)

17. Counterweight mounting bolt 20 3 30 400 (41) (297)

8 13 20 (2) (14)

10 17 49 (5) (36)

12 19 88 (9) (65)

14 22 137 (14) (101)

18. Front pin lock plate bolts

16 24 205 (21) (152)

IMPORTANT:

• Before installing, clean the bolt and nut threads to remove soil, rust, and/or dust.

• When installing new bolts and/or nuts, apply lubricant (e.g. white zinc B solved into spindle oil) to

the screw threads.

• Tighten bolts and nuts to the specifications. If tightened with excessively high or inadequate torque,

missing or breakage of bolts and/or nut may result.

• In case the counterweight mounting bolts became loose, consult your nearest Hitachi dealer for

retightening.

Loading...

Loading...