MAINTENANCE

7-7

MAINTENANCE GUIDE

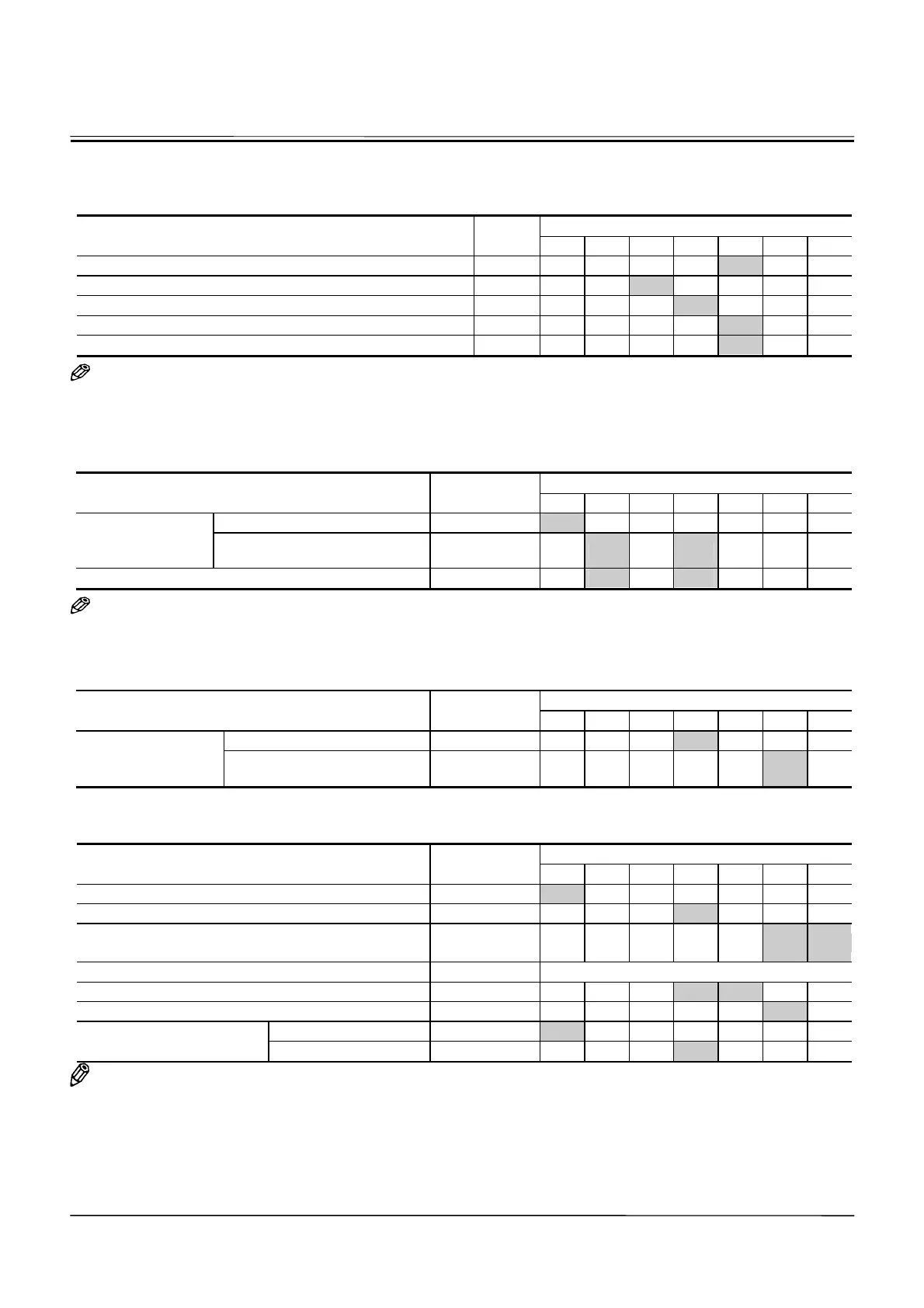

A. GREASING (See Page 7-11)

Interval (hours)

Parts Quantity

8 50 100 250 500 1000 2000

1. Front Joint Pins (Incl. around the swing post) 9 Ì ÌÌ

2. Bucket and Link Pins 5 Ì

3. Swing Bearing 1

4. Swing Internal Gear 1

5. Control Lever Universal Joint 2

NOTE:

Ì

Grease all submerged pins after operating in water.

Grease all pins daily during break-in operation for 50 hours.

ÌÌ

Grease all pins every 100 hours only during first time operation up to 500 hours.

B. ENGINE (See Page 7-17)

Intervals (Hours)

Parts Quantity

8 50 100 250 500 1000 2000

Oil Level Check – 1. Engine oil

Change

3.1 L

(3.2 US qt)

ÌÌ Ì

2. Replacement of engine oil filter 1 ÌÌ

NOTE:

Ì

The oil life is shortened more than normal under high temperature operating, shorten the mainte-

nance interval.

ÌÌ

For the first time only.

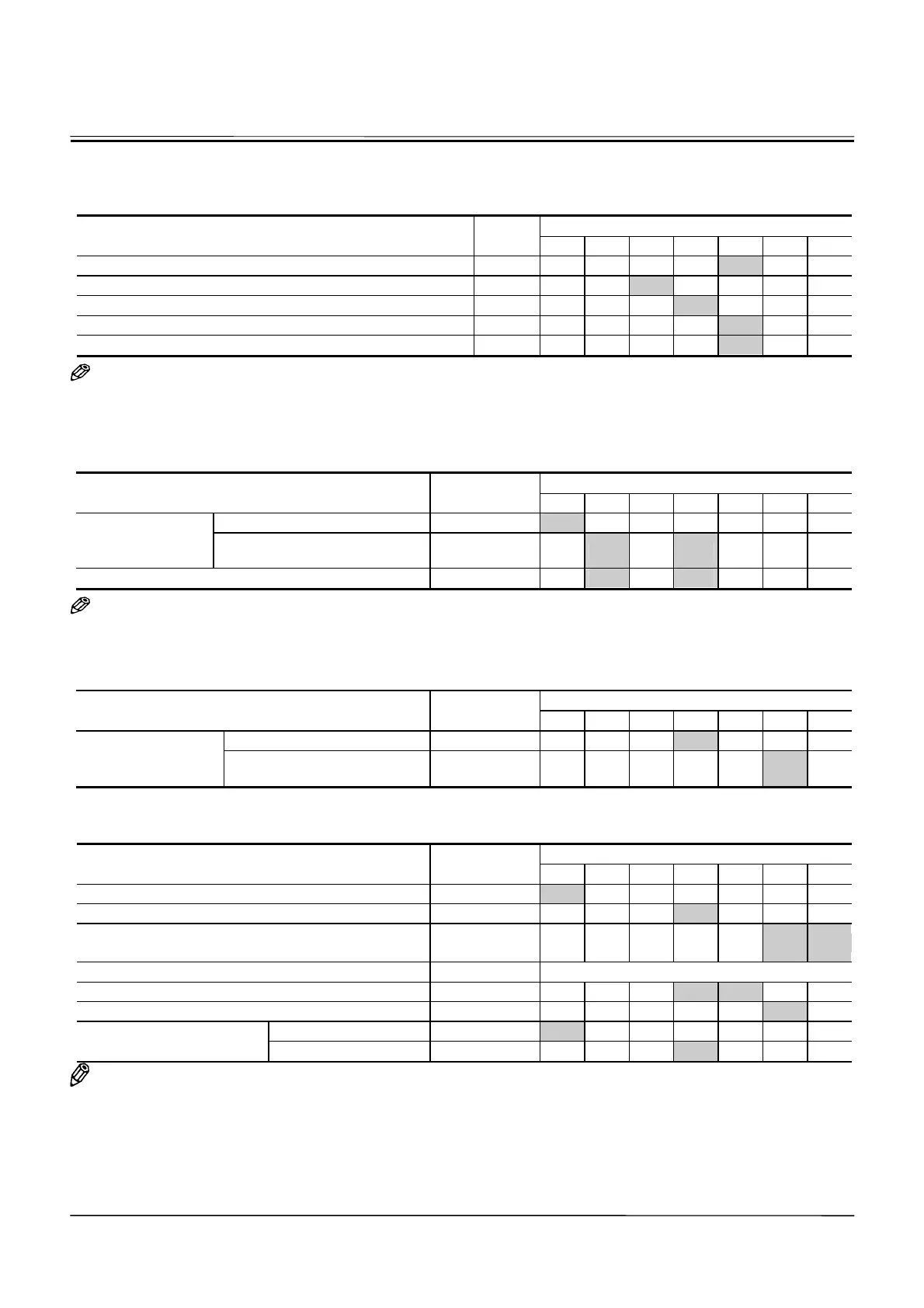

C. TRANSMISSION (See Page 7-19)

Interval (hours)

Parts Quantity

8 50 100 250 500 1000 2000

Oil Level Check –

1. Travel Reduction

Gear

Change

0.25 L×2

(0.26 US qt)×2

D. HYDRAULIC SYSTEM (See Page 7-21)

Interval (hours)

Parts Quantity

8 50 100 250 500 1000 2000

1. Check Hydraulic Oil Level 1

2. Drain Hydraulic Oil Tank Sump 1

3, Change Hydraulic Oil

30L

(7.9Us gal)

Ì Ì

4. Clean Suction Filter 1 When changing hydraulic oil

5. Replace Full Flow Filter Element 1 ÌÌ

6. Replace Pilot Filter Element 1

for leaks or looseness –

7. Check Hoses and Lines

for cracks, bend, etc.

–

NOTE:

Ì

Hydraulic oil changing intervals differ according to kind of hydraulic oils used.

See recommended oil chart.

ÌÌ

For the first time only.

Loading...

Loading...