MAINTENANCE

7-16

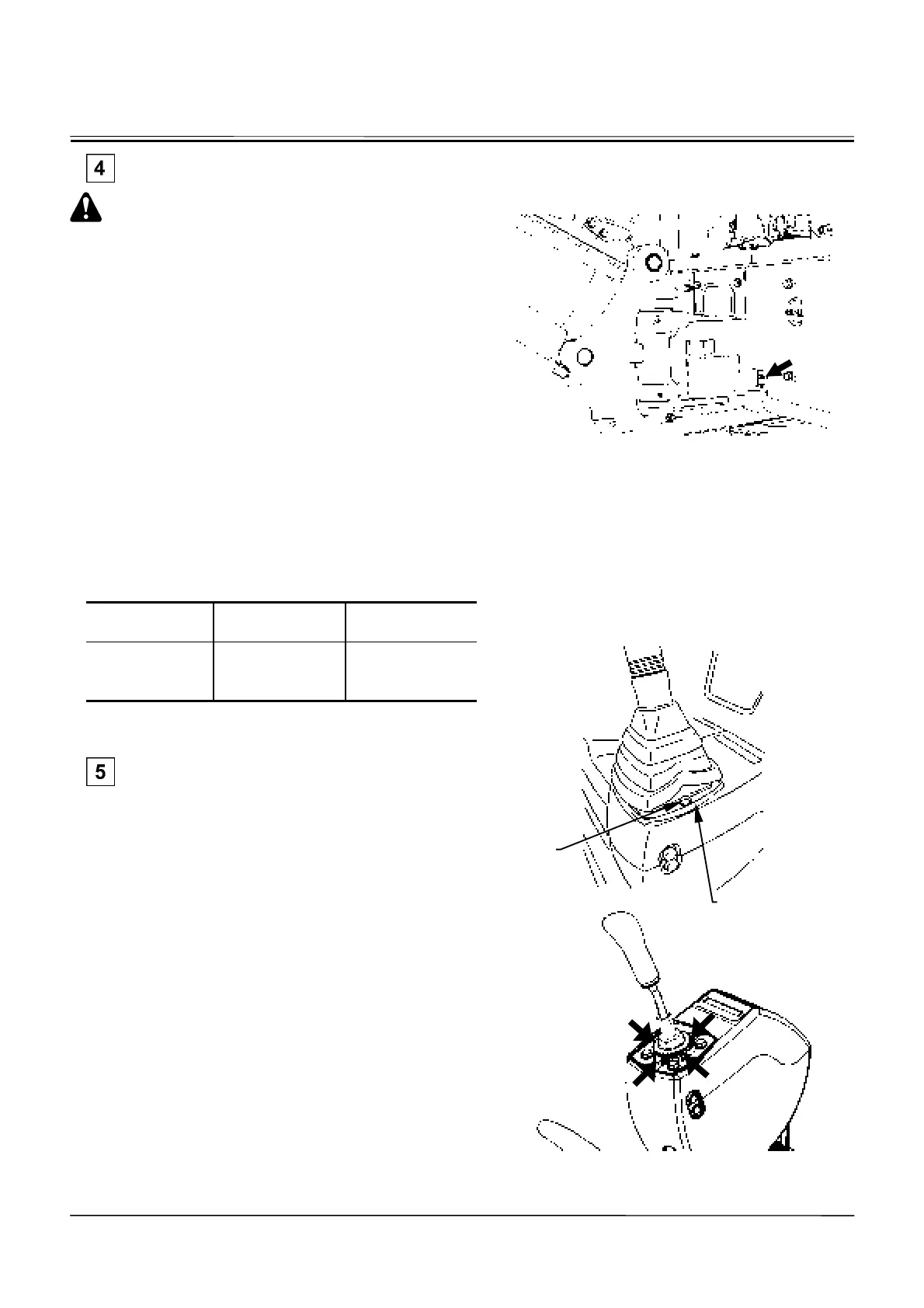

Swing Internal Gear --- every 500 hours

WARNING: Before lubricating the swing bearing,

lower the bucket and the blade to the ground,

stop the engine, and place the pilot control

shut-off lever to the LOCK position. Lubrication

and rotation of the upperstructure must be done

by one person only. Be sure to check that no

personnel are present around the machine before

starting to work.

1.

Remove the cover from the bottom center of the

undercarriage.

Check if grease inside is cloudy due to mixing of

water or dirt.

2. Apply grease via grease fittings by the quantity

shown in the table

3. In order to apply grease evenly to the swing gear,

raise the bucket approximately 200 mm (8 in)

above the ground. While swinging the upperstruc-

ture at approximately 90° intervals until one full turn

is made, add grease at each interval.

Greasing

Quantity

Total Grease

Capacity

ZAXIS17U-2

0.2 L

(0.2 US qt)

0.6 L

(0.6 US qt)

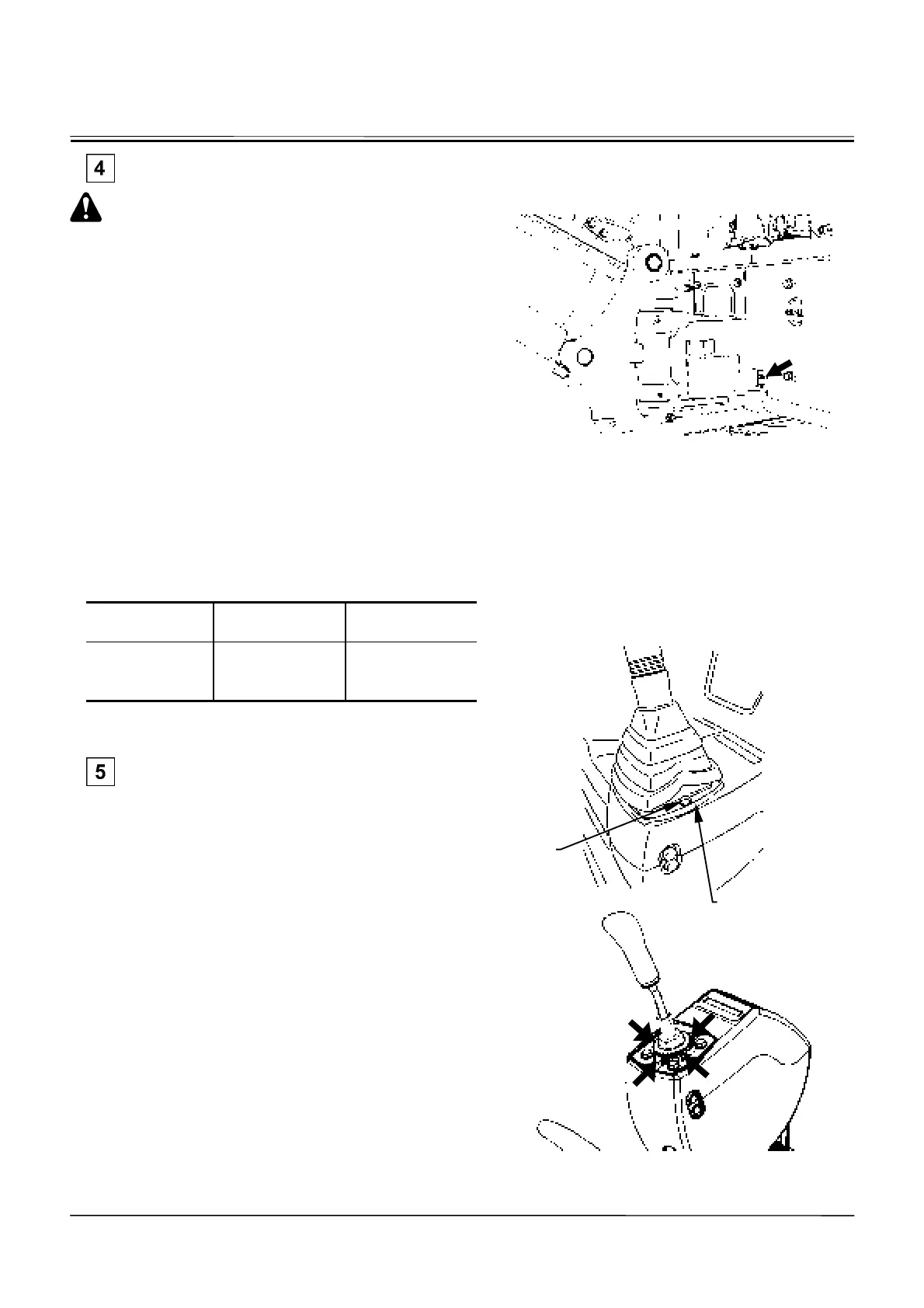

Control Lever Universal Joint

--- every 500 hours or yearly

Pull up the rubber boots under the right and left control

levers, remove two screws (1) to remove bracket (2).

After moving the rubber boots upward, add grease to the

four places of the pilot valve pushers as indicated by

arrows.

M1MS-07-008

M1M7-07-026

M1M7-07-016

1

2

Loading...

Loading...