Powermax125 Service Manual 808070 81

6 – Machine Torch Setup

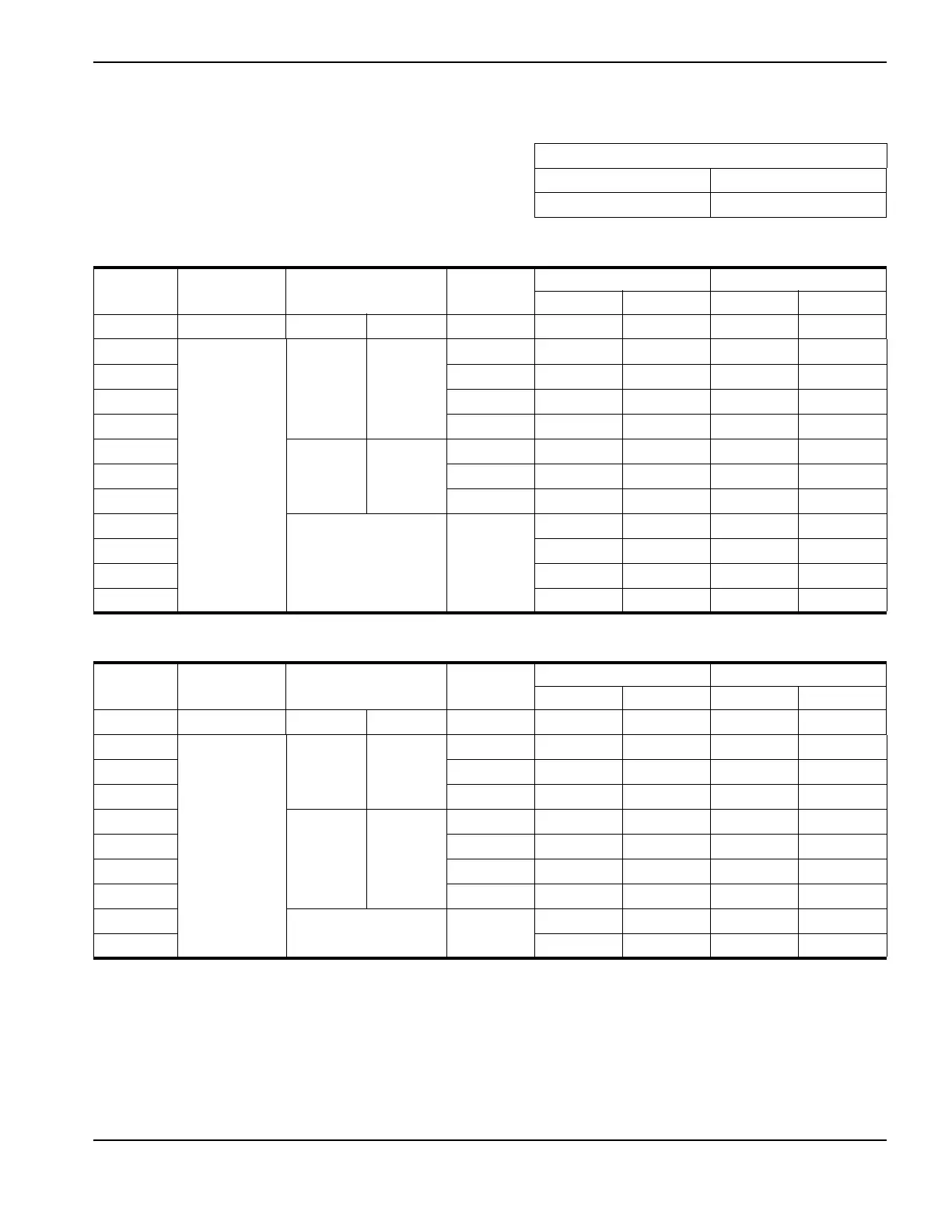

125 A shielded cutting – mild steel

Air flow rate – slpm/scfh

Hot 260 / 550

Cold 345 / 730

Metric

Material

Thickness

Torch-to-Work

Distance

Initial Pierce Height

Pierce

Delay Time

Best Quality Settings Production Settings

Cut Speed Voltage Cut Speed Voltage

mm mm mm % seconds mm/min volts mm/min volts

6

4.6

9.2 200

0.2 4980 158 5960 155

8 0.3 3800 158 4570 157

10 0.4 2750 158 3330 158

12 0.5 2050 157 2510 157

16

11.5 250

0.6 1260 162 1660 164

20 2.0 980 165 1140 164

25 3.5 610 169 780 167

30

Edge Start* 1.0

580 169 510 167

32 400 174 500 172

35 340 177 430 175

40 240 180 310 178

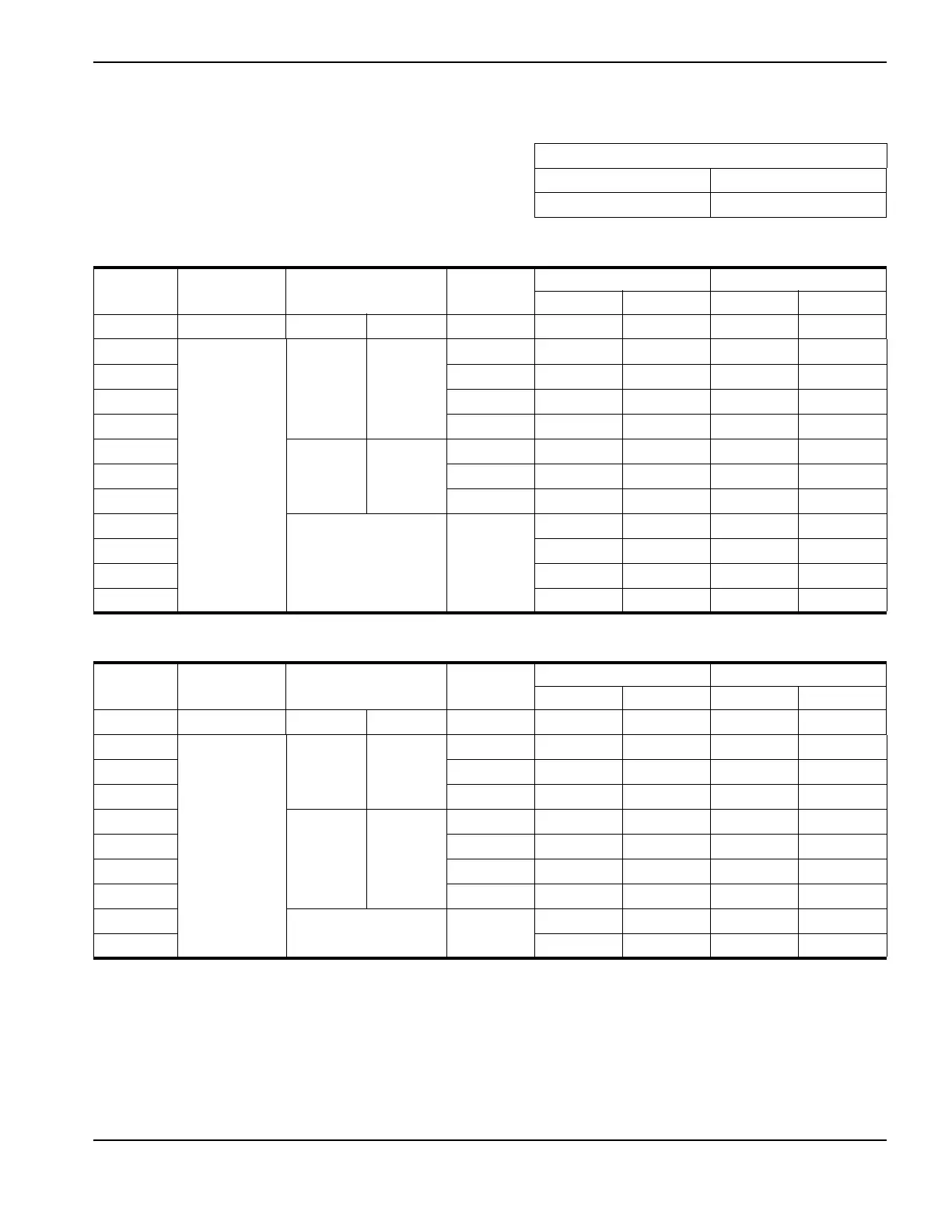

English

Material

Thickness

Torch-to-Work

Distance

Initial Pierce Height

Pierce

Delay Time

Best Quality Settings Production Settings

Cut Speed Voltage Cut Speed Voltage

inches inches inches % seconds ipm volts ipm volts

1/4

0.18

0.36 200

0.2 188 158 225 155

3/8 0.4 114 158 138 158

1/2 0.5 75 158 93 158

5/8

0.45 250

0.6 50 162 66 164

3/4 0.8 42 164 48 163

7/8 2.0 31 168 37 166

1 3.5 23 169 30 167

1-1/4

Edge Start* 1.0

16 174 20 172

1-1/2 11 179 14 177

* You can pierce thicknesses up to 32 mm (1-1/4 inch) if your CNC software and torch height control system enable you to

temporarily raise the torch in order to clear the puddle of dross that can form during the pierce. In Hypertherm’s Phoenix CNC

software, for example, this function is referred to as the “puddle jump height.” Using this piercing function may affect consumable

life.

Loading...

Loading...