G 7

0708.USA

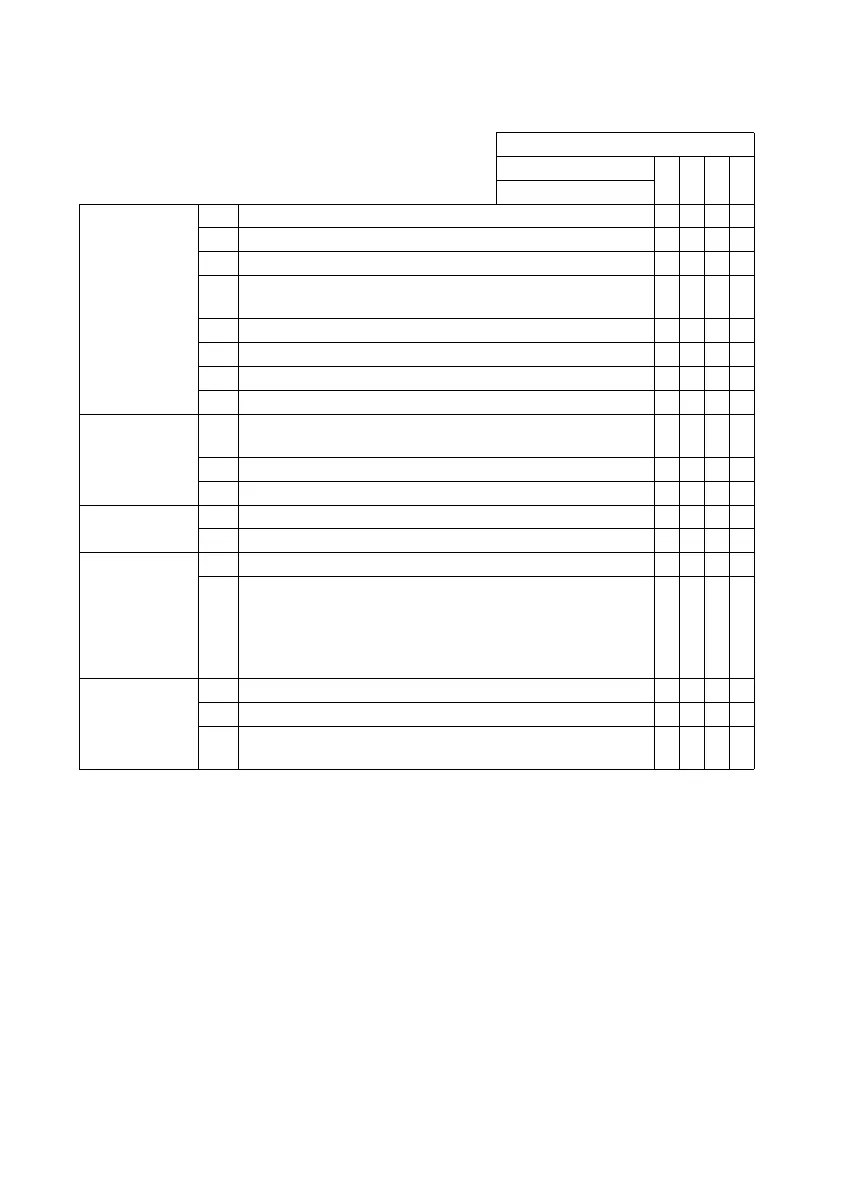

4 EKS 314 maintenance checklist

Maintenance intervals

Standard = t WABC

Chassis/

Structure:

1.1 Check all load bearing components for damage t

1.2 Check screw connections t

1.3 Test the operator’s platform and check for damage t

1.4 Check that identification points, data plates and warning

labels are legible and replace if necessary

t

1.5 Check tilt safety devices are present and secure t

1.7 Make sure decals are present, legible and valid t

1.8 Check battery panel and sides are secure t

1.9 Test battery panel attachment and check for damage t

Drive: 2.1 Lubricate the bearing between the drive motor and

transmission

t

2.2 Check transmission for noise and leakage t

2.3 Change transmission oil t

Wheels: 3.1 Check wheels for wear and damage t

3.2 Check and lubricate bearing and attachment t

Steering: 4.1 Test operation and setting of wheel position display t

4.2 Check the distance between the guide rollers and the

rail guidance over the entire length of the rails. The play

between the two guide rollers and the rails (measured

over the axle) should be 0-5 mm/0-0.2 inches. The roll-

ers should not jam.

t

Brake sys-

tem:

5.1 Test operation and settings t

5.2 Check the brake lining wear t

5.3 Check brake mechanism, adjust and lubricate if

necessary

t

G 7

0708.USA

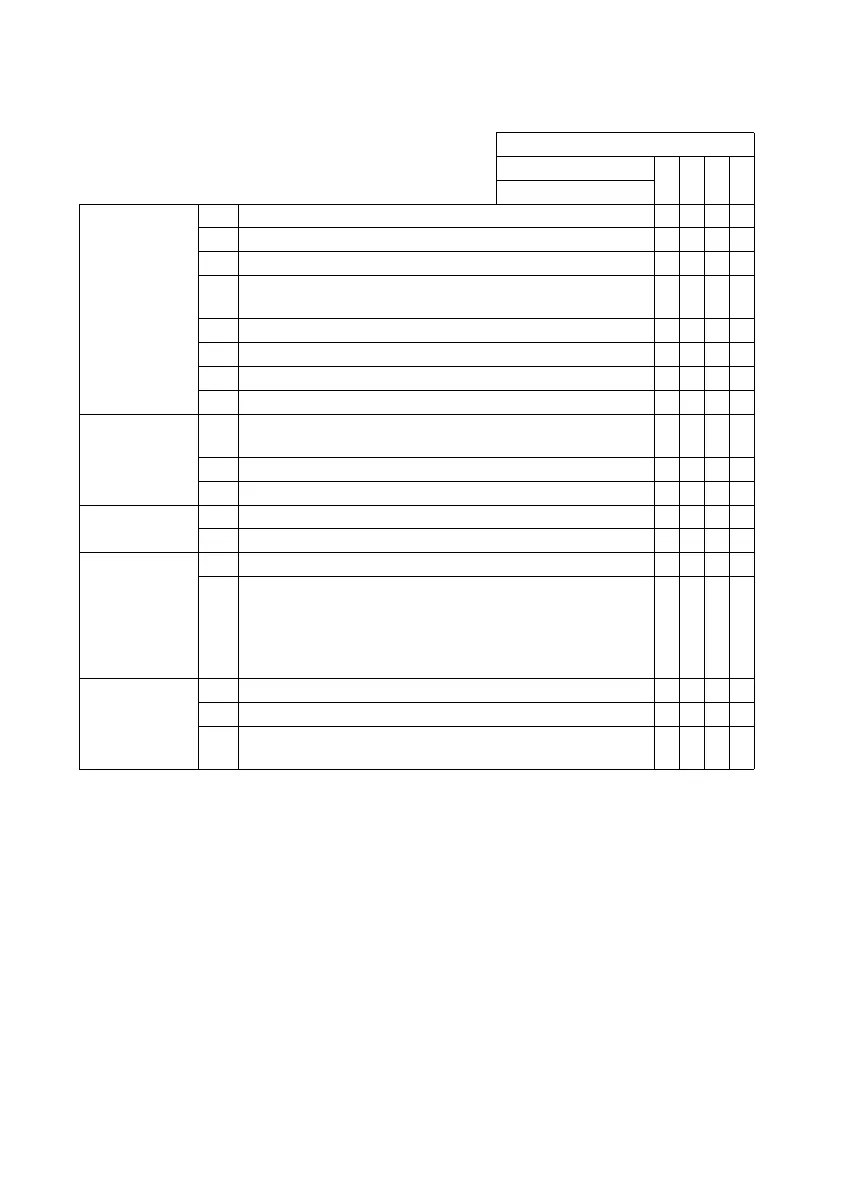

4 EKS 314 maintenance checklist

Maintenance intervals

Standard = t WABC

Chassis/

Structure:

1.1 Check all load bearing components for damage t

1.2 Check screw connections t

1.3 Test the operator’s platform and check for damage t

1.4 Check that identification points, data plates and warning

labels are legible and replace if necessary

t

1.5 Check tilt safety devices are present and secure t

1.7 Make sure decals are present, legible and valid t

1.8 Check battery panel and sides are secure t

1.9 Test battery panel attachment and check for damage t

Drive: 2.1 Lubricate the bearing between the drive motor and

transmission

t

2.2 Check transmission for noise and leakage t

2.3 Change transmission oil t

Wheels: 3.1 Check wheels for wear and damage t

3.2 Check and lubricate bearing and attachment t

Steering: 4.1 Test operation and setting of wheel position display t

4.2 Check the distance between the guide rollers and the

rail guidance over the entire length of the rails. The play

between the two guide rollers and the rails (measured

over the axle) should be 0-5 mm/0-0.2 inches. The roll-

ers should not jam.

t

Brake sys-

tem:

5.1 Test operation and settings t

5.2 Check the brake lining wear t

5.3 Check brake mechanism, adjust and lubricate if

necessary

t

Loading...

Loading...