6 11

KEB COMBIVERT F4-C

6

Name: Basis

30.01.98

Functional Description PI-Controller

© KEB Antriebstechnik, 1997

All Rights reserved

Chapter Section Page

Date

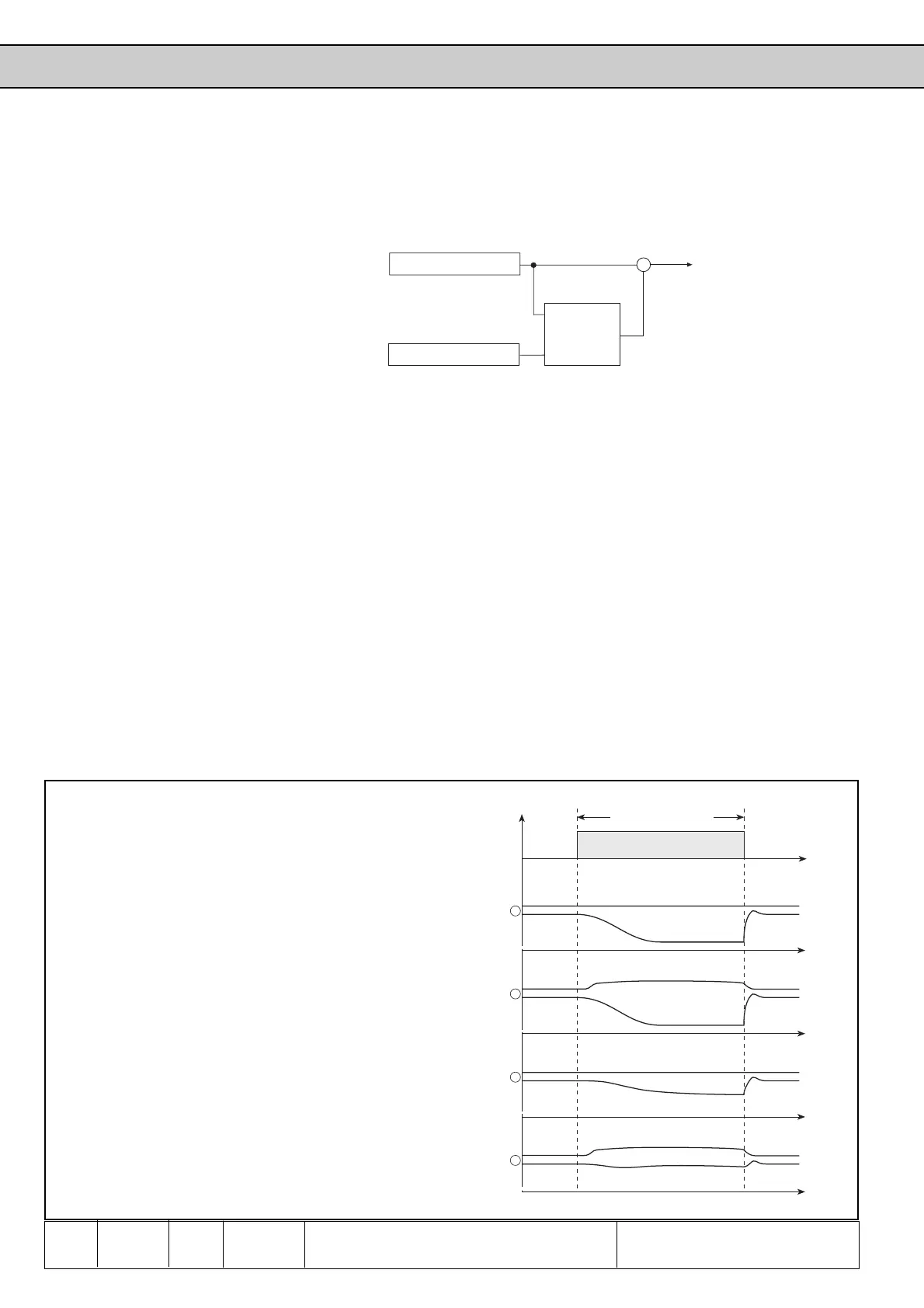

cn.0 Bit 1 and 2 = „3“

Set value

Actual value

PI-Controller

Speed detection

f

Presetting

+

+

f_out

This setting requires the optional available speed detection card (see Chap. 6.9) to

record the actual value. Speed controls with incremental encoder, tacho generator or

pulse encoder can be set up.

At high load torques autoboost causes an automatic I•R compensation by increasing

the output voltage; the magnetizing current remains constant. The slip compensation

compensates the speed changes caused by load changes.

The combination of both functions improves the performance over the entire speed

range. During regenerative operation, only with positive voltage change, a smoother

braking behaviour is adjusted with autoboost (cn.0 bit 7).

1. Enter motor data (Cahpter 6.6)

2. Activate autoboost and slip compensation (see cn.0)

3. Adjust parameter cn.1 and cn.2 to „0.00“

4. Measure the speed on idling machine. Put a load on the machine and repeat

the measurement. If nesessary, adjust parameters cn.1 and cn.2 to the desired

speed/torque performance characteristic.

5. Take the load off the machine. Check, whether voltage and frequency are

reduced again.

6.11.3 Autoboost and

Slip

Compensation

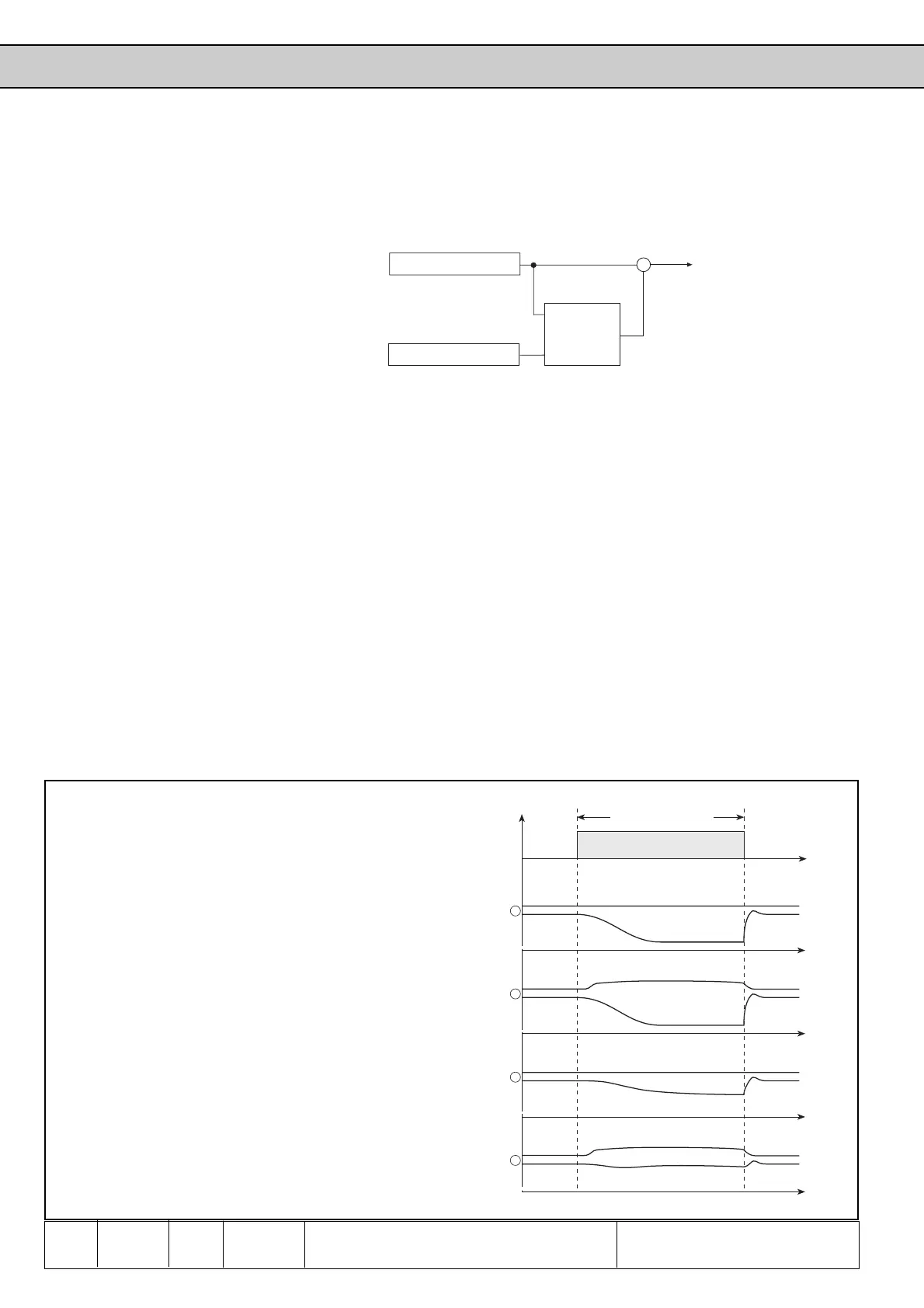

f

n

Mot

f

n

Mot

f

n

Mot

f

n

Mot

d

c

b

a

f / n

Mot

t

=

=

=

=

a) No frequency rise, speed decays => no controller

activated or adjusted too low.

b) Frequency is increased, speed decays => voltage

rise too little or not existing.

c) No frequency rise, speed decays => frequency rise

too little or not existing.

d) Speed is maintained after a short adjustment phase

=> optimal setting.

Picture 6.11.3 Autoboost and slip compensation

Load

Loading...

Loading...