ENGINE

L3560, L4060, L4760, L5060, L5460, L6060, WSM

1-S92

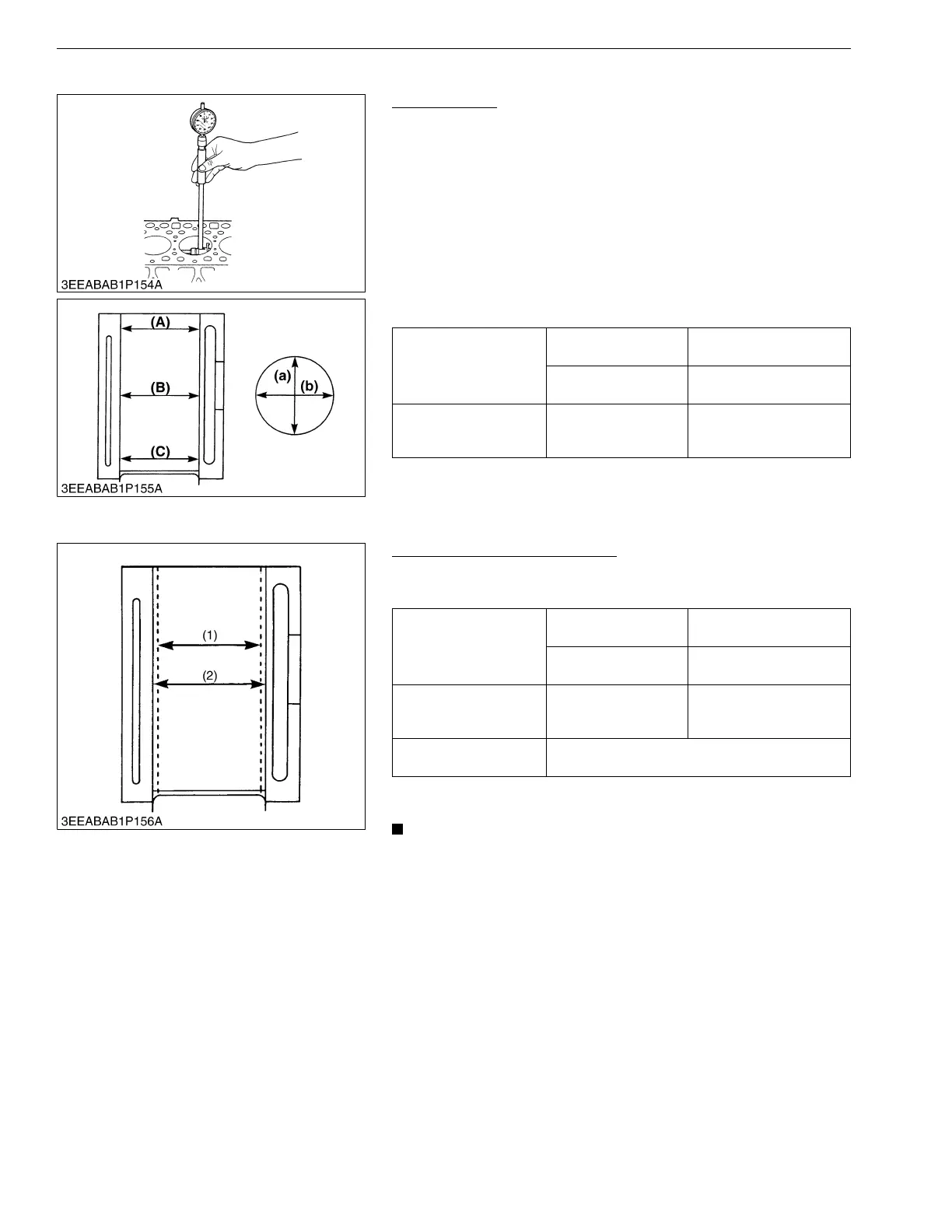

[5] CYLINDER

Cylinder Wear

1. Measure the I.D. of the cylinder at the 6 positions (see figure)

with a cylinder gauge.

2. Find the maximum and minimum inner diameters.

3. Find the difference between the maximum and the minimum

inner diameters.

4. If the maximum I.D. or the difference is more than the allowable

limit, bore and hone it to the oversize dimension. (Refer to

"Cylinder Correction (Oversize)".).

5. Examine the cylinder wall for scratches. If you find deep

scratches, bore the cylinder. (Refer to "Cylinder Correction

(Oversize)".)

9Y1210824ENS0104US0

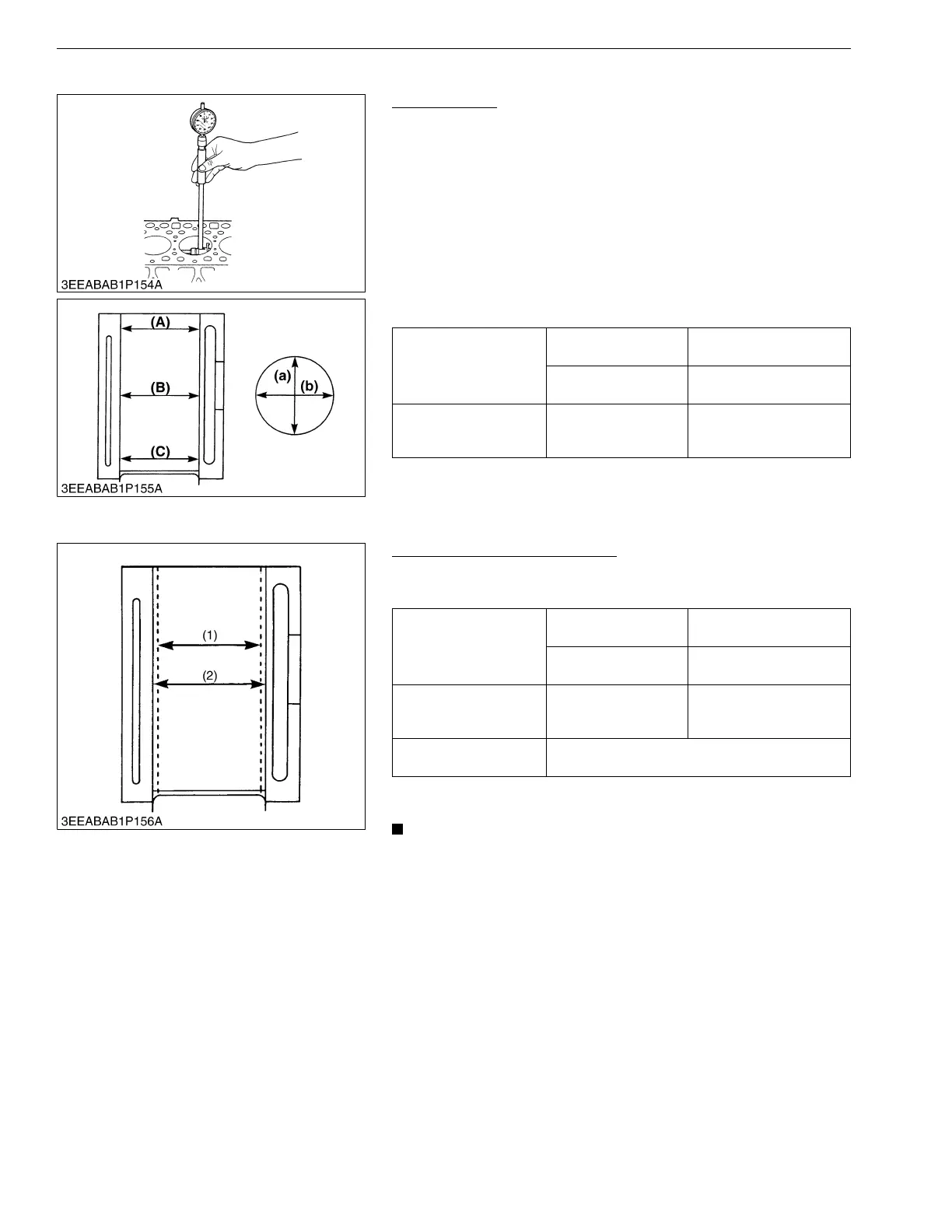

Cylinder Correction (Oversize)

1. If the cylinder wear is more than the allowable limit, bore and

hone it to the specified dimension.

2. Replace the piston and piston rings with oversize ones.

Oversize : 0.25 mm (0.0098 in.)

• If the maximum I.D. or the difference for the oversize

cylinder is more than the allowable limit, replace the

cylinder block with a new one.

9Y1210824ENS0105US0

Cylinder I.D.

Factory specification

87.000 to 87.022 mm

3.4252 to 3.4260 in.

Allowable limit

87.170 mm

3.4319 in.

Difference between

maximum I.D. and

minimum I.D.

Allowable limit

0.15 mm

0.0059 in.

(A) Top

(B) Middle

(C) Bottom (Skirt)

(a) Right-angled to Piston Pin

(b) Piston Pin Direction

Oversize cylinder I.D.

Factory specification

87.250 to 87.272 mm

3.4351 to 3.4359 in.

Allowable limit

87.420 mm

3.4417 in.

Difference between

maximum I.D. and

minimum I.D.

Allowable limit

0.15 mm

0.0059 in.

Finishing

Hone to 2.2 to 3.0 µmRz

(0.000087 to 0.000118 in.Rz)

(1) Cylinder I.D. (Before Correction) (2) Cylinder I.D. (Oversize)

Loading...

Loading...