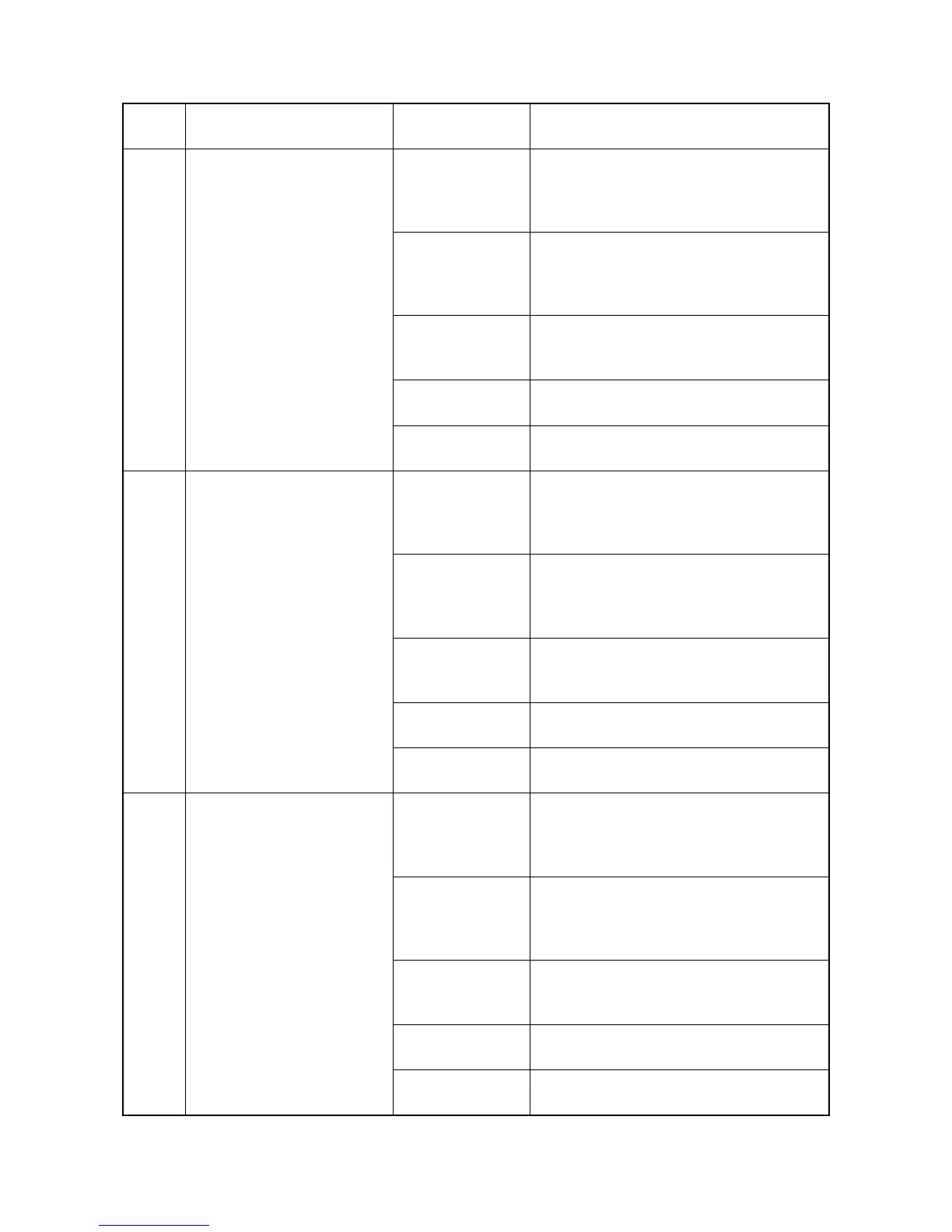

2MN/2N1

1-4-30

1030 PF lift motor 1 error

(paper feeder)

After cassette 3 is inserted,

PF lift sensor 1 does not turn

on within 12 s. This error is

detected 5 times successively.

During driving the motor, the

lift overcurrent protective

monitor signal is detected for

1 s or more 5 times succes-

sively. However, the first 1 s

after motor is turned on is

excluded from detection.

Defective bottom

plate elevation

mechanism in the

cassette.

Check to see if the bottom plate can move

smoothly and repair it if any problem is

found.

Defective connec-

tor cable or poor

contact in the con-

nector.

Reinsert the connector. Also check for conti-

nuity within the connector cable. If none,

replace the cable.

PF lift motor 1 and PF main PWB (YC7)

Defective drive

transmission sys-

tem of motor.

Check if the gears rotate smoothly. If not,

grease the bushes and gears. Check for

broken gears and replace if any.

Defective PF lift

motor 1.

Replace the PF lift motor 1.

Defective PF main

PWB.

Replace the PF main PWB (Refer to the ser-

vice manual for the paper feeder).

1040 PF lift motor 2 error

(paper feeder)

After cassette 4 is inserted,

PF lift sensor 2 does not turn

on within 12 s. This error is

detected 5 times successively.

During driving the motor, the

lift overcurrent protective

monitor signal is detected for

1 s or more 5 times succes-

sively. However, the first 1 s

after motor is turned on is

excluded from detection.

Defective bottom

plate elevation

mechanism in the

cassette.

Check to see if the bottom plate can move

smoothly and repair it if any problem is

found.

Defective connec-

tor cable or poor

contact in the con-

nector.

Reinsert the connector. Also check for conti-

nuity within the connector cable. If none,

replace the cable.

PF lift motor 2 and PF main PWB (YC7)

Defective drive

transmission sys-

tem of motor.

Check if the gears rotate smoothly. If not,

grease the bushes and gears. Check for

broken gears and replace if any.

Defective PF lift

motor 2.

Replace the PF lift motor 2.

Defective PF main

PWB.

Replace the PF main PWB (Refer to the ser-

vice manual for the paper feeder).

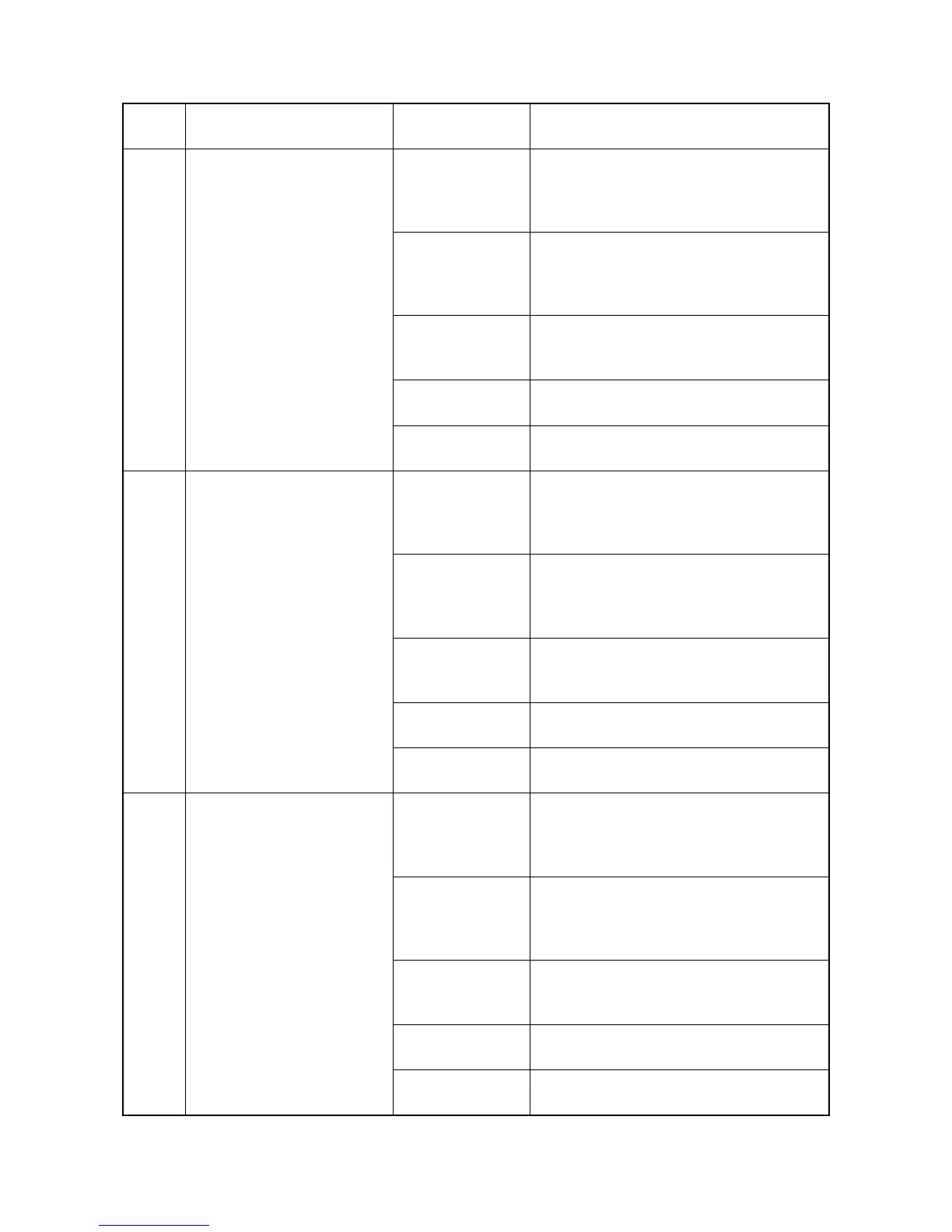

1050 SM lift motor error

(side multi tray)

[45 ppm/55 ppm model]

After cassette 5 is inserted,

SM lift sensor does not turn

on within 12 s. This error is

detected 5 times successively.

(Time to detect is 2 seconds

at the second time and later.)

During driving the motor, the

lift overcurrent protective

monitor signal is detected for

1 s or more 5 times succes-

sively. However, the first 1 s

after motor is turned on is

excluded from detection.

Defective bottom

plate elevation

mechanism in the

cassette.

Check to see if the bottom plate can move

smoothly and repair it if any problem is

found.

Defective connec-

tor cable or poor

contact in the con-

nector.

Reinsert the connector. Also check for conti-

nuity within the connector cable. If none,

replace the cable.

SM lift motor and SM main PWB (YC5)

Defective drive

transmission sys-

tem of motor.

Check if the gears rotate smoothly. If not,

gre

ase the bushes and gears. Check for

broken gears and replace if any.

Defective SM lift

motor.

Replace the SM lift motor.

Defective SM main

PWB.

Replace the SM main PWB (Refer to the

service manual for the paper feeder).

Code Contents Causes

Check procedures/

corrective measures

Loading...

Loading...