INTRODUCTION RT9150E OPERATOR MANUAL

1-12

Published 2-23-2017, Control # 644-00

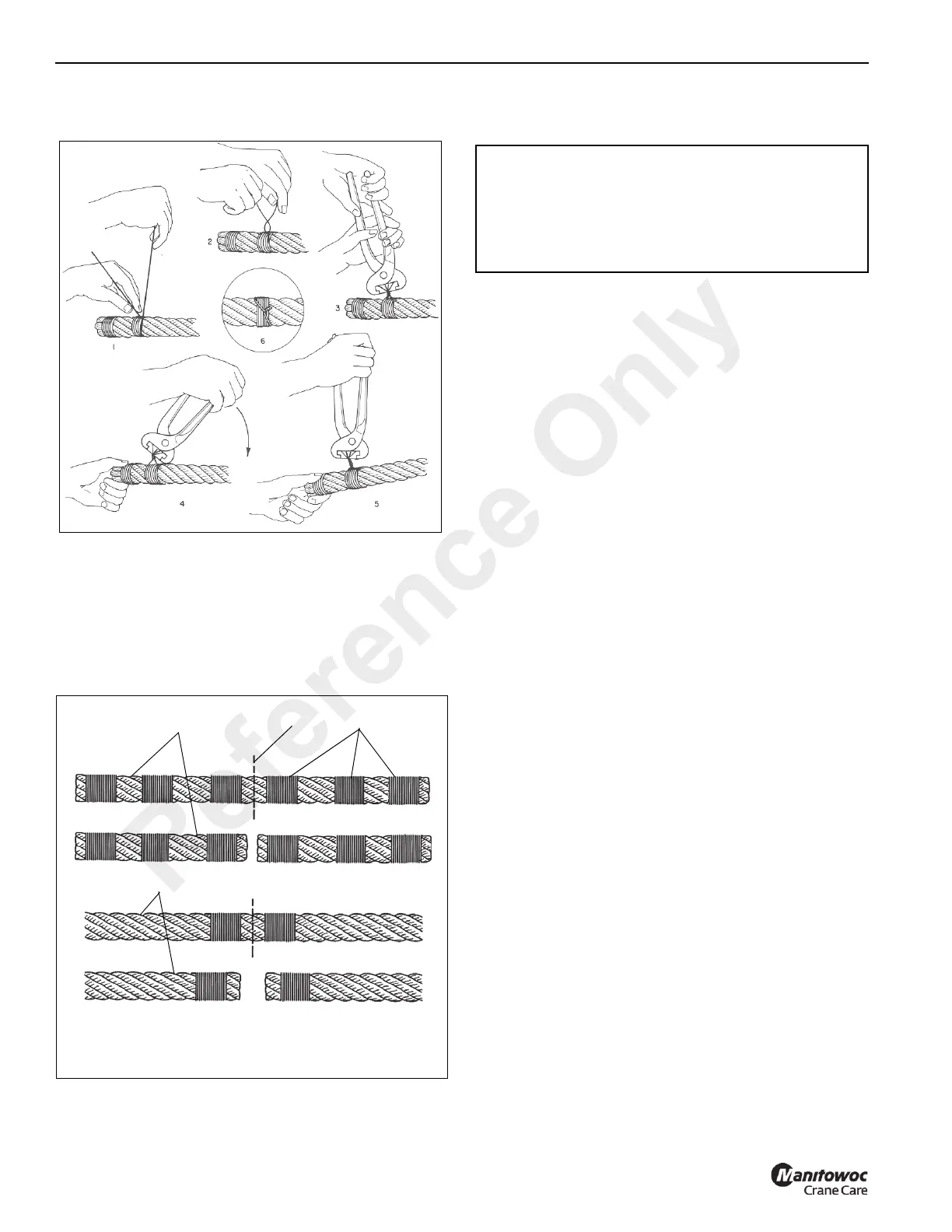

Method 2

Wind a length of soft annealed wire (Figure 1-6) around the

wire rope at least seven times. The two ends should be

twisted together in the center of the seizing. Tighten the

seizing by alternately prying and twisting. Cut off both ends

of the wire and pound the twist flat against the rope.

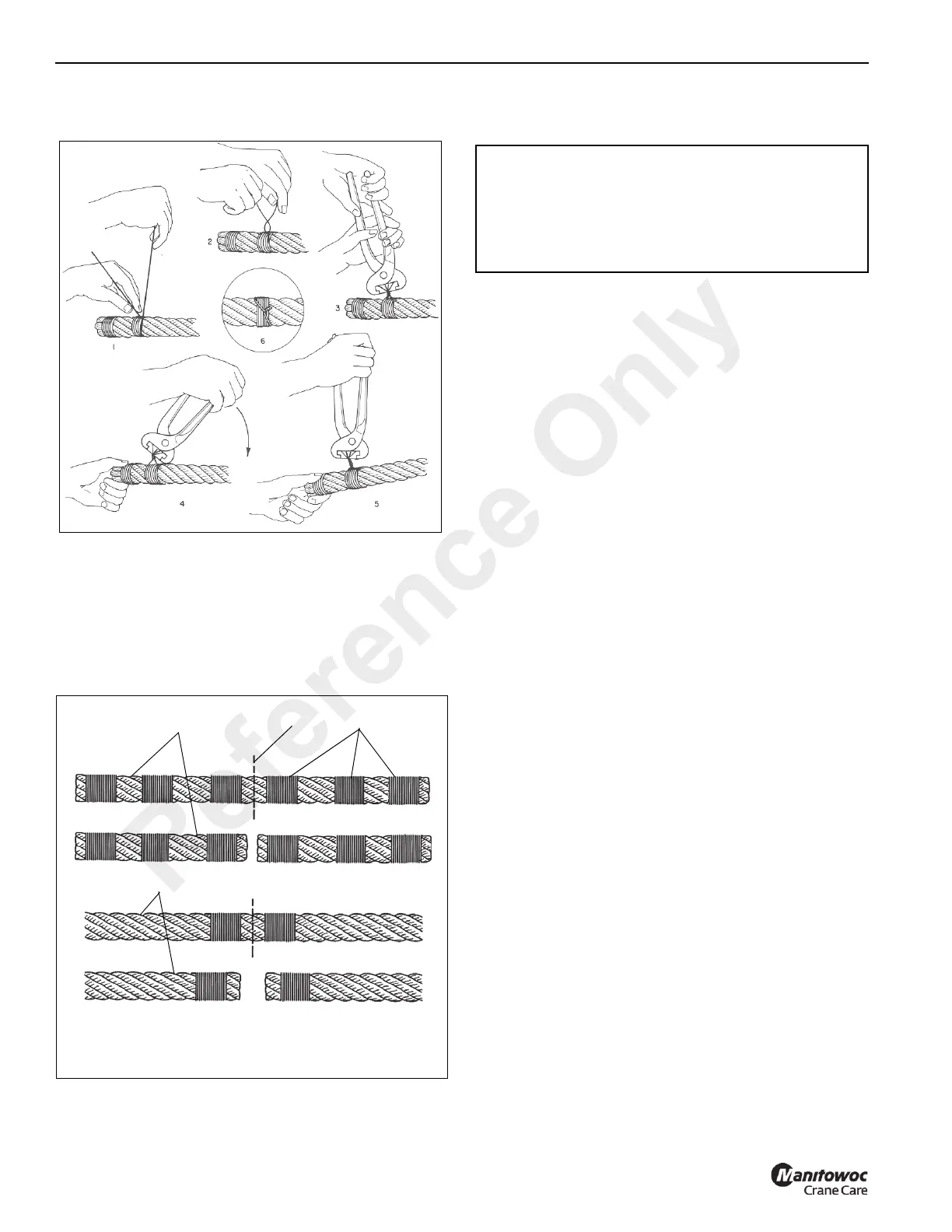

NOTE: Non-preformed wire rope (1) (Figure 1-7) should

have three seizings (3) located on each side of the

cut (4) as compared to preformed wire rope (2).

Installing 35x7 Class Wire Rope

1. Unload properly and relieve any twists. Pull the rope off

the shipping reel or unroll it from a shipping coil. (If done

improperly, you may kink the rope, which will result in

permanent damage to the rope.) Then, lay the rope on

the ground in direct line with the boom. This helps

release any twist in the rope.

2. Pull the rope over the point sheave and attach the end to

the hoist drum. Be sure not to remove the welded end.

3. Wind rope onto drum slowly and carefully. At this point, it

isn’t necessary to provide additional load other than the

weight of the rope being pulled across the ground.

4. Spool first layer tightly. It is essential on smooth-faced

drums that the first layer is spooled with wraps tight and

close together since the first layer forms the foundation

for succeeding layers. If need be, use a rubber, lead or

brass mallet (but never a steel hammer) to tap the rope

into place.

5. Spool multiple layers with sufficient tension. It’s very

important to apply a tensioning load to the ropes during

the rope breaking-in process. (If not, the lower layers

may be loose enough that the upper layers become

wedged into the lower layers under load, which can

seriously damage the rope.) The tensioning load should

range from 1 to 2% of the rope’s minimum breaking

force.

6. For ropes in multi-part systems: Reeve the traveling

block and boom tip sheaves so the rope spacing is

maximized and the traveling (hook) block hangs straight

and level to help assure block stability.

7. Breaking in new 35x7 class rope—After installation,

properly break in the rope, which allows the rope’s

component parts to adjust themselves to the operating

conditions:

With the boom fully raised and fully extended, attach a

light load at the hook and raise it a few inches off the

ground. Allow to stand for several minutes. Then cycle

the load between the full “up” and “down” positions

several times. Observe the drum winding and rope travel

for any potential problems.

After making the lifts with a light load, increase the load

and cycle it up and down a few times. This procedure will

CAUTION

Any cutting of this specific wire rope is not recommended.

If 35x7class wire rope must be cut for any reason, it is

necessary to follow the following instructions. Also, unlike

other types of wire rope, the ends on this wire rope must

be welded to retain the rotation resistant characteristics.

Reference Only

Loading...

Loading...