OPERATING CONTROLS AND PROCEDURES MLC650 VPC-MAX™ OPERATOR MANUAL

3-4

Published 04-06-18, Control # 231-14

specified and make sure the proper counterweight

position column of the capacity chart is selected before

raising or lowering the boom.

• If required per the rigging drawing in use (boom and

luffing jib), make sure the intermediate suspension is

properly installed. Otherwise, damage to the boom and

jib sections can occur.

For some boom and luffing jib configurations, it is normal

for the intermediate suspension to appear slack during

boom and luffing jib raising and operation. If your

intermediate suspension appears slack —

- make sure it is installed in the proper location,

- make sure the proper pendant buttons are pinned to

the sockets,

and continue operation.

• The counterweight assembly will remain in its last

position when the engine is turned off during operation.

• Operate only with the crane on a firm surface that is

uniformly supporting:

- With load, grade must not exceed 1% in any

direction — 1 ft in 100 ft (0,3 m in 30 m).

- Without load, see Maximum Allowable Travel

Specifications Chart.

- During crane operation, the elevation outside of the

crawlers may be up to 152 mm (6 in) above the

grade of the crawlers to 610 mm (24 in) below the

grade of the crawlers. Also, the grade outside of the

crawlers shall not exceed 5% in any direction.

These conditions apply to any area the auxiliary

frame assembly will pass over.

• Prior to using the crane each day, inspect the VPC and

VPC-MAX roller paths on the rotating bed and beam for

obvious obstructions and/or signs of damage. Remove

the obstructions. Contact the Manitowoc Crane Care

Lattice Team for inspection and repair criteria.

• Do not operate the crane, to include raising the boom

from ground level, if the wind exceeds the limits given in

Capacity Charts. Monitor the wind speed in the working

screen of the crane’s RCL/RCI Display or contact your

local weather station. See Wind Conditions in the

Capacity Chart Manual.

• Be aware of increased tail swing with the VPC-MAX

counterweight assembly. The counterweight assembly

can strike objects or personnel in the area of the travel

and swing paths.

• Warn all personnel to stand well clear of the crane. The

VPC-MAX counterweight assembly extends and retracts

automatically without warning — it can strike personnel.

Anytime the VPC-MAX counterweight assembly moves,

an audible alarm will sound and the amber lights on the

counterweight tray and beam will flash to warn

personnel to stay clear.

• Provide a signal person for all crane operations.

Have signal person watch for clearance behind and

under the counterweight assembly while swinging and

traveling. Do not allow the counterweight to strike

obstructions or contact the foundation.

Depending on lifted load, clearance under the auxiliary

frame assembly will vary from 254 mm (10 in) to 1,5 m

(5 ft).

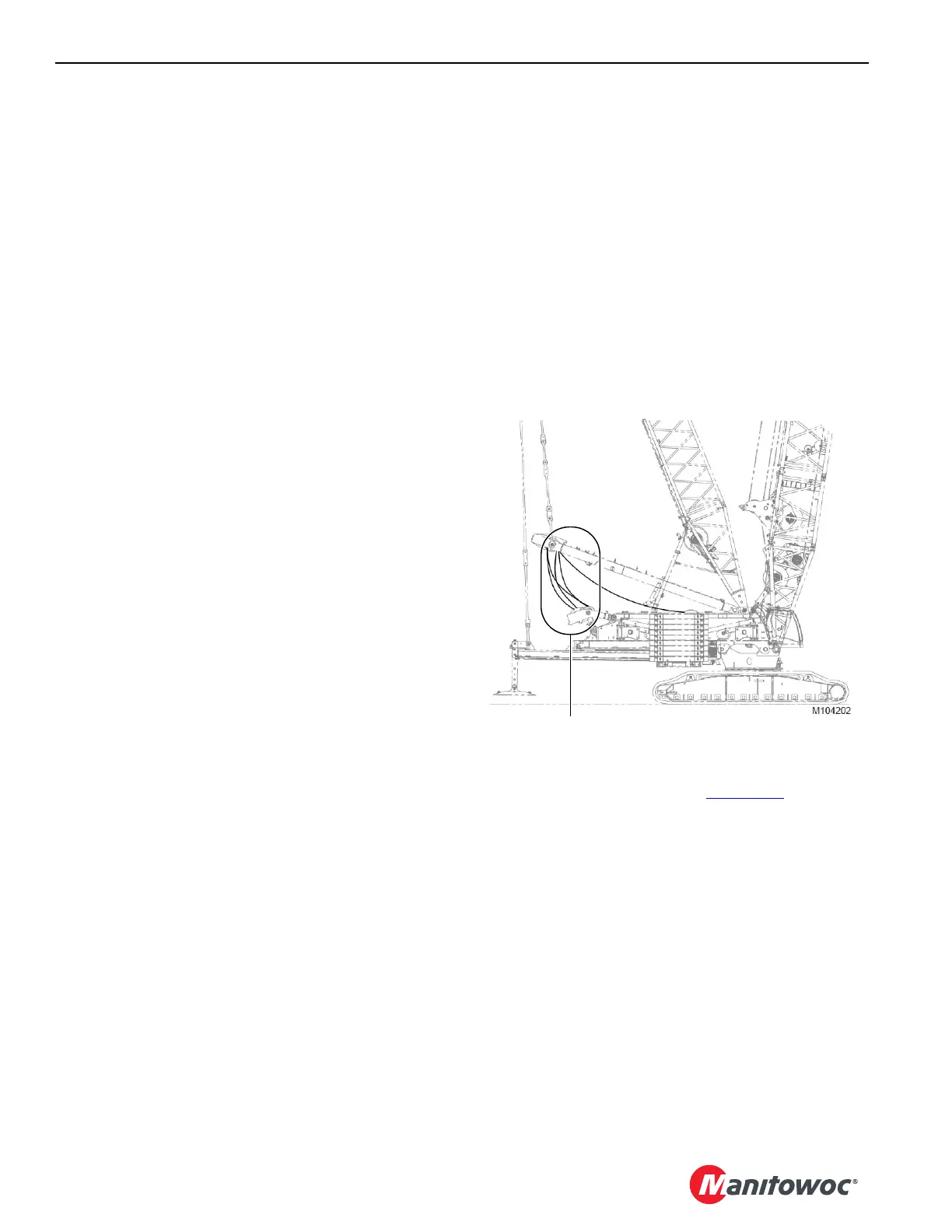

• During operation, it is normal for the live mast wire rope

reeving to become slack (Figure 3-1

) when the

counterweight tray is at the minimum working position.

This most commonly occurs when operating at high

boom angles with light loads.

When this condition occurs, the VPC-MAX beam will be

supported by the beam hooks resting on the rotating bed

pins.

• When the crane is left unattended, park it as instructed in

Section 3 of Crane Operator Manual. If the boom cannot

be lowered to the ground, position it at the mid-point of

the boom angle range given in the Capacity Chart.

FIGURE 3-1

Slack Here is Normal

Loading...

Loading...