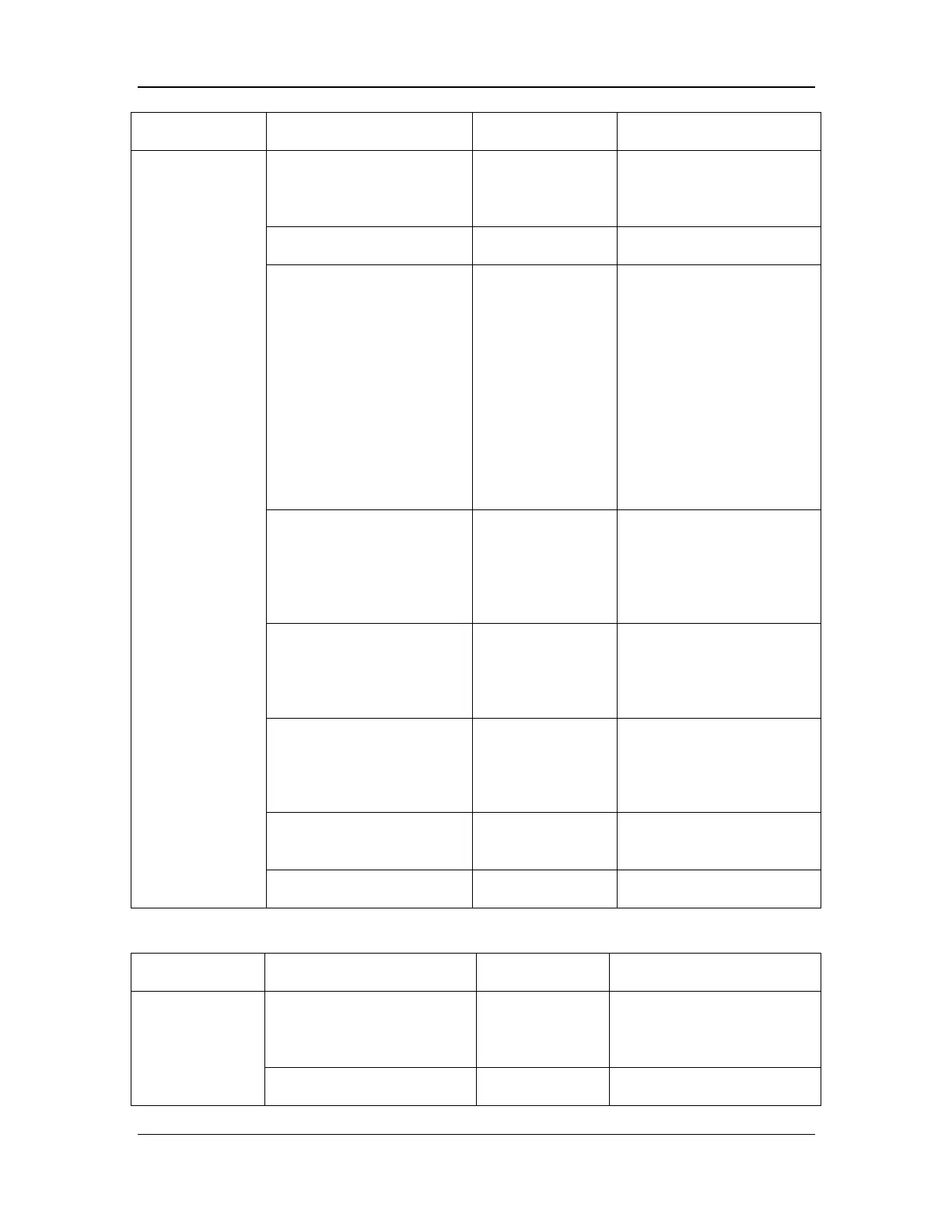

7-48

Cause Confirmation

Solution

for further analysis

by referring to

replace the sensor (refer to

11.5.2).

Check the zero point of the

sensor by referring to 5.15.

Refer to 5.15.

Zero the sensor by referring

to 6.3.7.

If there is a significant

difference (greater than ±10

mL/min or 5% of the

setting) between TVe and

TVi displayed on the UI,

perform the constant-flow

test by referring to 5.16, or

perform flow sensor

diagnosis by referring to

7.6.1.2.

between TVe/TVi

displayed on the

UI and the flow

setting of the

machine exceeds

5% or 0.5 L/min,

or

the flow difference

found in flow

sensor diagnosis in

7.6.1.2

exceeds

1. Calibrate the flow sensor

by referring to 6.3.1.

(2) If the problem persists,

replace the sensor (refer to

11.5.2).

(3) If the problem persists,

replace the sensor adapter

board (refer to 11.1.16).

measurement of the pressure

sensor is accurate by

referring to

5.17 (device

required) or 7.6.1.3

(no

Make a judgment

by referring to 5.17

or 7.6.1.3.

calibration by referring to

6.3.5.

(2) If the problem persists,

replace the sensor adapter

board (refer to 11.1.16).

Open the service door (refer

to 8.1.1) and check whether

the sensor adapter board and

3-way valve sampling line

The silicone tube

loosens or is

occluded.

Reconnect the silicone tube

and prevent it from

occlusion.

by referring to 8.29 and

check whether the sampling

line on the work surface is

The silicone tube

loosens or is

occluded.

Reconnect the silicone tube

and prevent it from

occlusion.

technical alarms are

technical alarm is

Refer to 7.3 to clear the

alarm.

The problem persists.

Replace the drive gas

assembly (refer to 11.1.17).

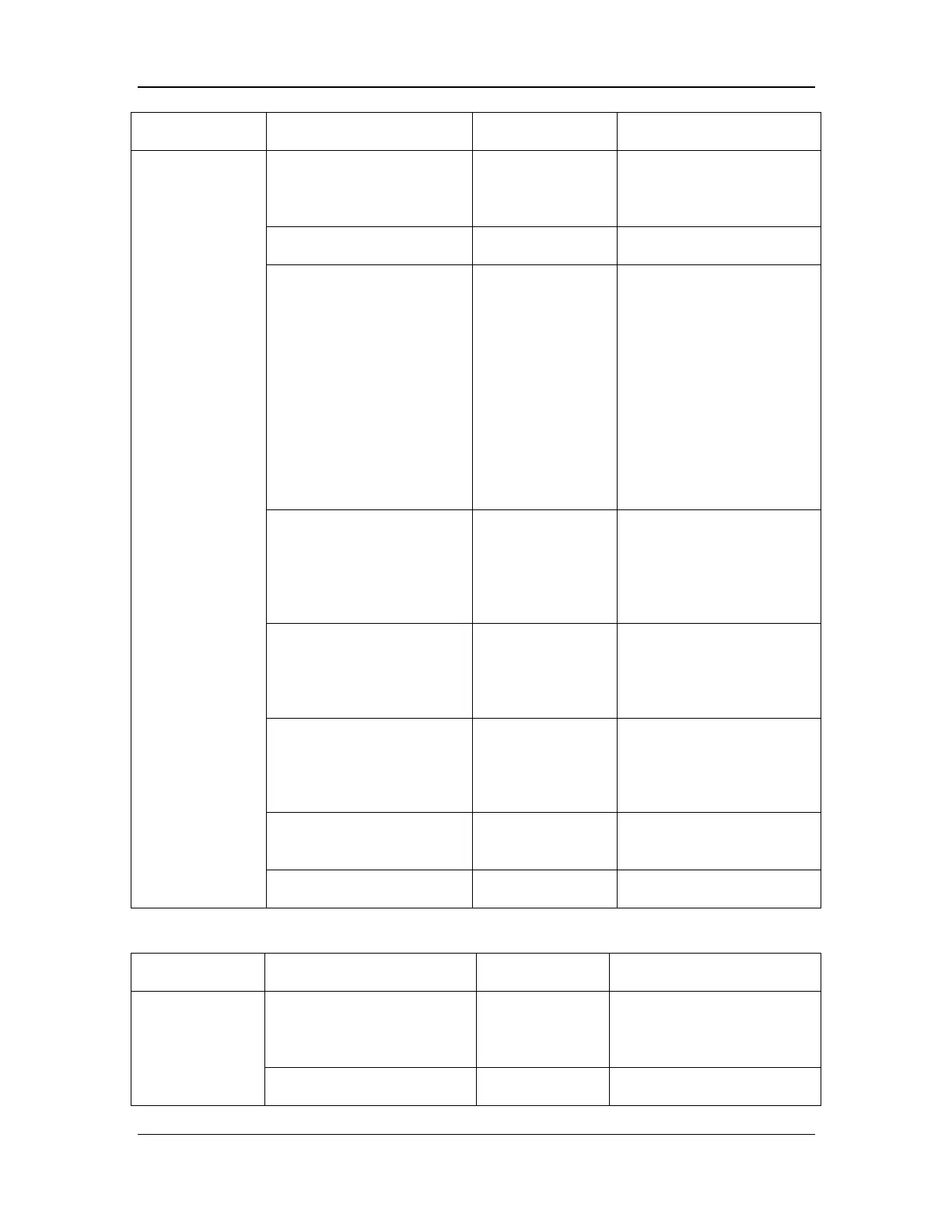

7.4.5 Inaccurate Airway Pressure Control

Cause Confirmation

Solution

Inaccurate

airway pressure

control in

pressure mode

Check whether the gas

supply is sufficient.

pressure is less

than 280 kPa (40

Connect or replace the gas

supply.

Check for leakage in the

breathing system.

The leakage is

greater than 200

Refer to 7.2.3.

Loading...

Loading...