8 SYSTEM APPLICATION EXAMPLES

8-134 Application Example 2

8.2.13 Safety response time

・ Safety data transmission time (maximum value): DTtrs

Calculate the maximum safety data transmission time [ms] (including error detections) from when the safety input

of the safety remote I/O module turns OFF until when the safety input SCNI of the robot controller turns OFF. The

following shows calculation examples.

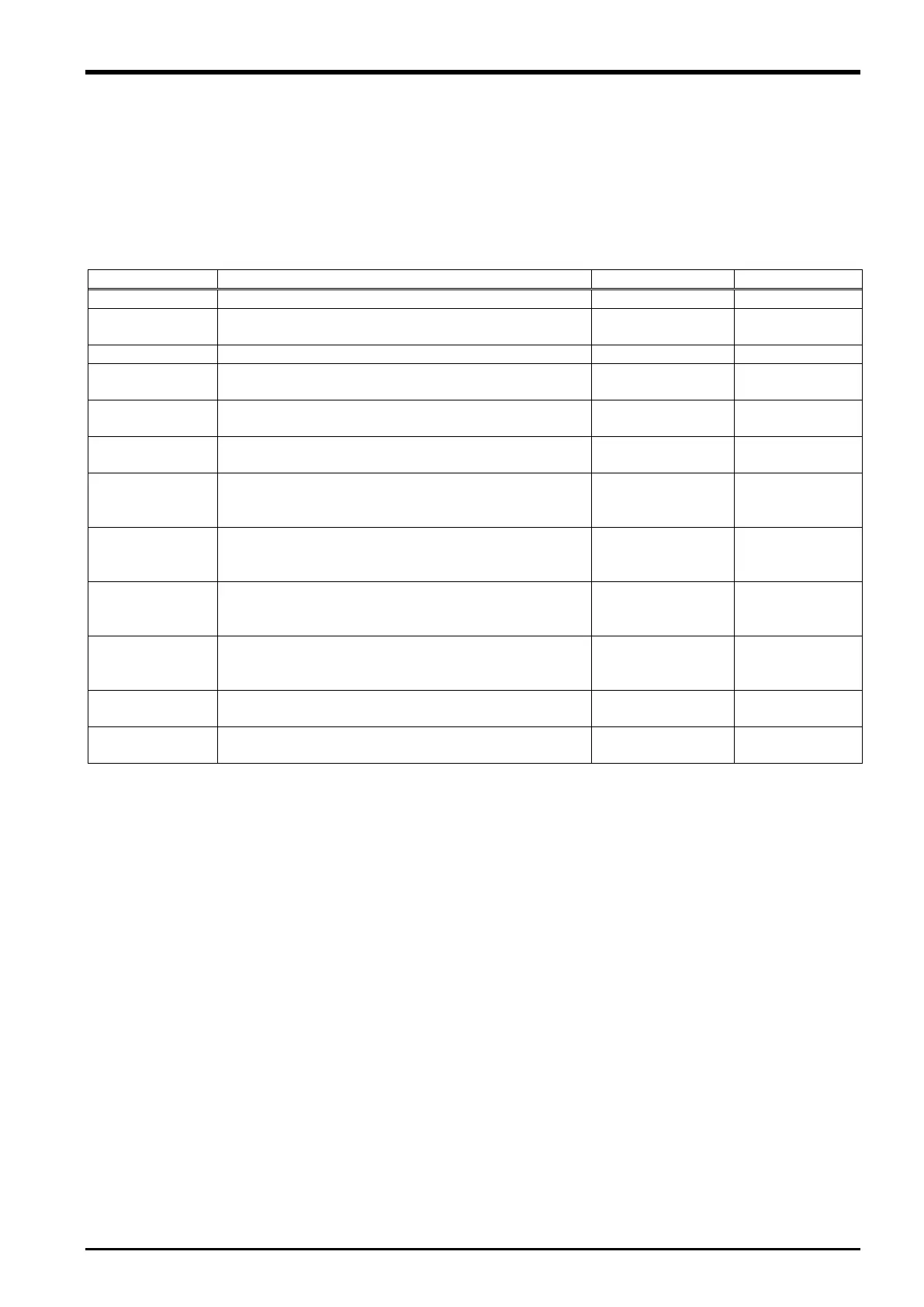

Table 8-17 Parameters

Safety cycle time of the safety CPU module

Refresh response processing time of the safety

remote I/O module

Safety cycle time of the robot controller

Safety refresh monitoring time

(Safety CPU module - Safety remote I/O module)

Safety refresh monitoring time

(Safety CPU module - Robot controller)

Input response time of the safety remote I/O

module

TMact1

Transmission interval monitoring time on the active

side

(Safety CPU module - Safety remote I/O module)

TMpas1

Transmission interval monitoring time on the

passive side

(Safety CPU module - Safety remote I/O module)

TMact2

Transmission interval monitoring time on the active

side

(Safety CPU module - Robot controller)

TMpas2

Transmission interval monitoring time on the

passive side

(Safety CPU module - Robot controller)

n1 n (Safety CPU module - Safety remote I/O module)

*1

n2 n (Safety CPU module - Robot controller)

*2

*1 (calculation of n1)

For safety connection between the safety CPU module and safety remote I/O module, b (a smallest multiple of

SCact which is greater than TMact /2) is 6.00, a (TMact - b) is 3.00, d (a smallest multiple of SCpas which is

greater than TMpas /2) is 4.00, and c (TMpas - d) is 4.00. "n1" is 2.00 since it is the lowest value of either 1) or

2) shown below.

1) RM - TMact - (TMpas /2) + a = 12.00 - 9.00 - (8.00 /2) + 3.00 = 2.00

2) RM - (TMact /2) - TMpas + c = 12.00 - (9.00 /2) - 8.00 + 4.00 = 3.50

*2 (calculation of n2)

For safety connection between the safety CPU module and robot controller, b (a smallest multiple of SCact

which is greater than TMact /2) is 9.00, a (TMact - b) is 7.30, d (a smallest multiple of SCpas which is greater

than TMpas /2) is 14.22, and c (TMpas - d) is 7.18. "n1" is 5.63 since it is the lowest value of either 1) or 2)

shown below.

1) RM - TMact - (TMpas /2) + a = 28.00 - 16.30 - (21.40 /2) + 7.30 = 8.30

2) RM - (TMact /2) - TMpas + c = 28.00 - (16.30 /2) - 21.40 + 7.18 = 5.63

Calculate the maximum safety data transmission time (DTtrs) as follows.

DTtrs = (SCcpu × 3) + (SRref × 2) + (SCrc × 2.5) + RM1 + RM2 + SRin + (n1 × 2) + (n2 × 2)

= (3.00 × 3) + (2.00 × 2) + (7.11 × 2.5) + 12.00 + 28.00 + 1.40 + (2.00 × 2) + (5.63 × 2)

= 87.5

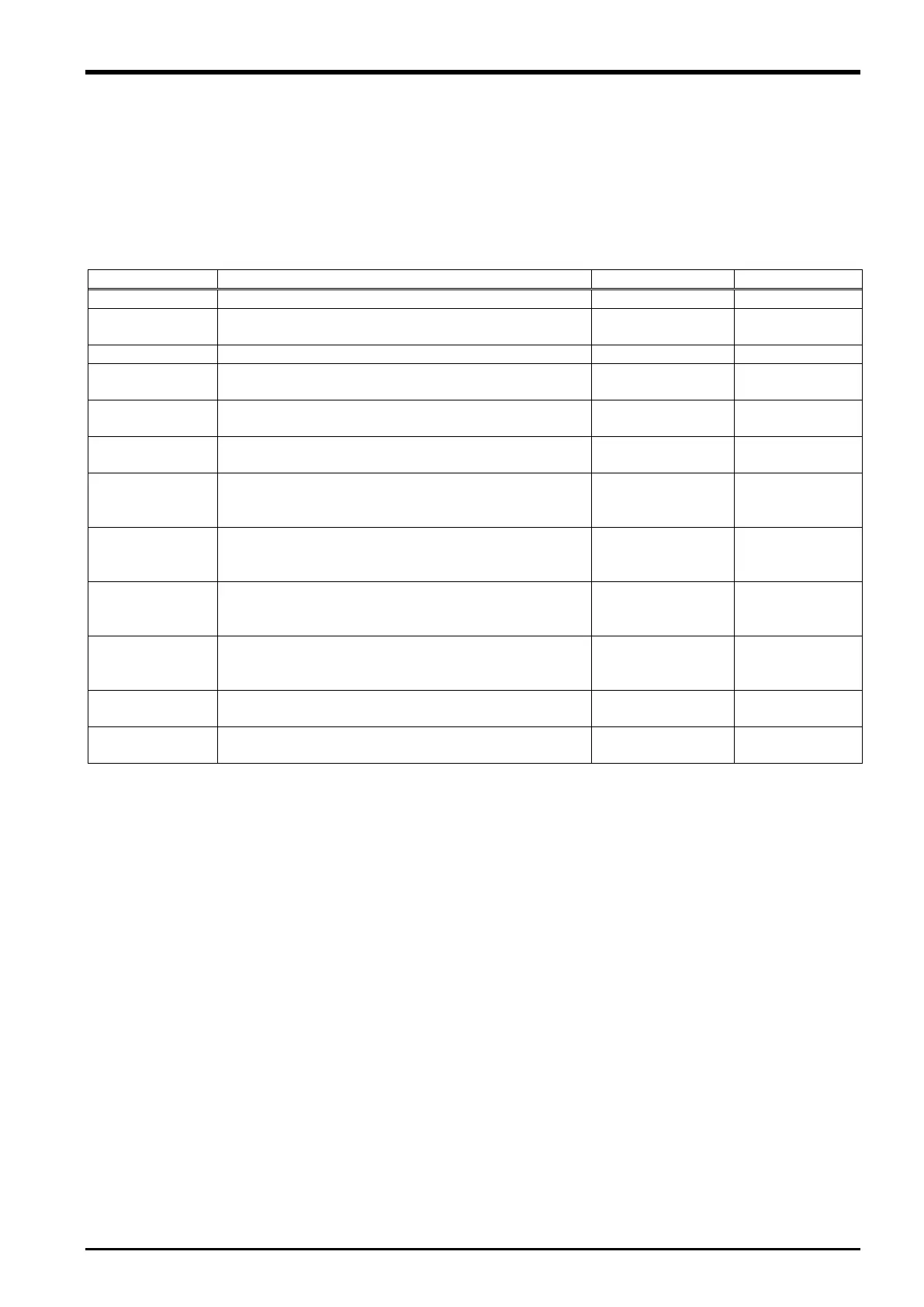

・ Safety response time (maximum value): SFRT

Calculate the safety response time (maximum value) [ms] from when the safety input devices (emergency stop

switch 1, emergency stop switch 2, safety sensor 1A, and safety sensor 2A) turn OFF until when the robot stops.

Loading...

Loading...