3 CONNECTIONS AND COMMUNICATION DESTINATION SETTINGS

Creating a Safety Program 3-15

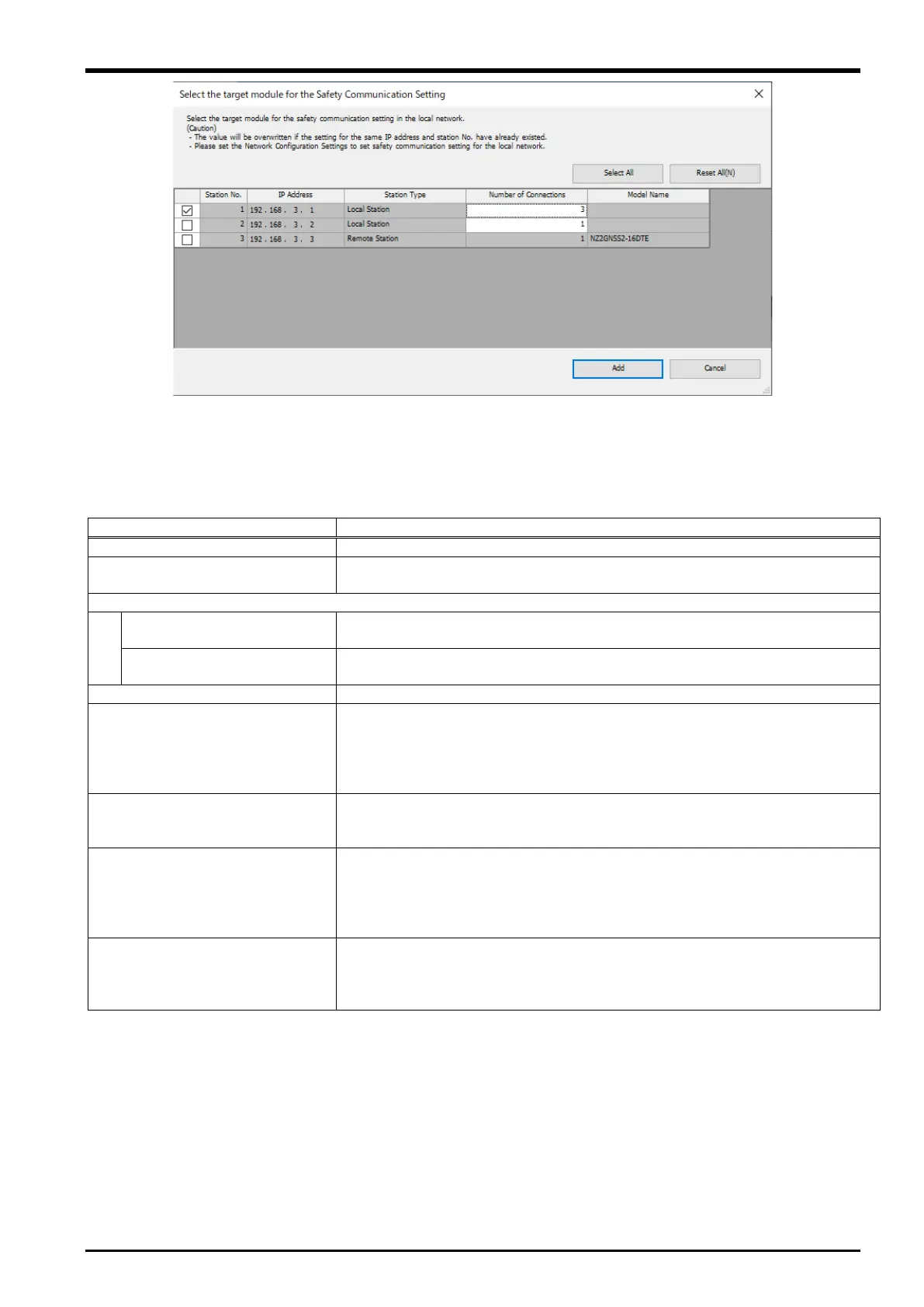

Fig. 3-3: Select the target module for the Safety Communication Setting

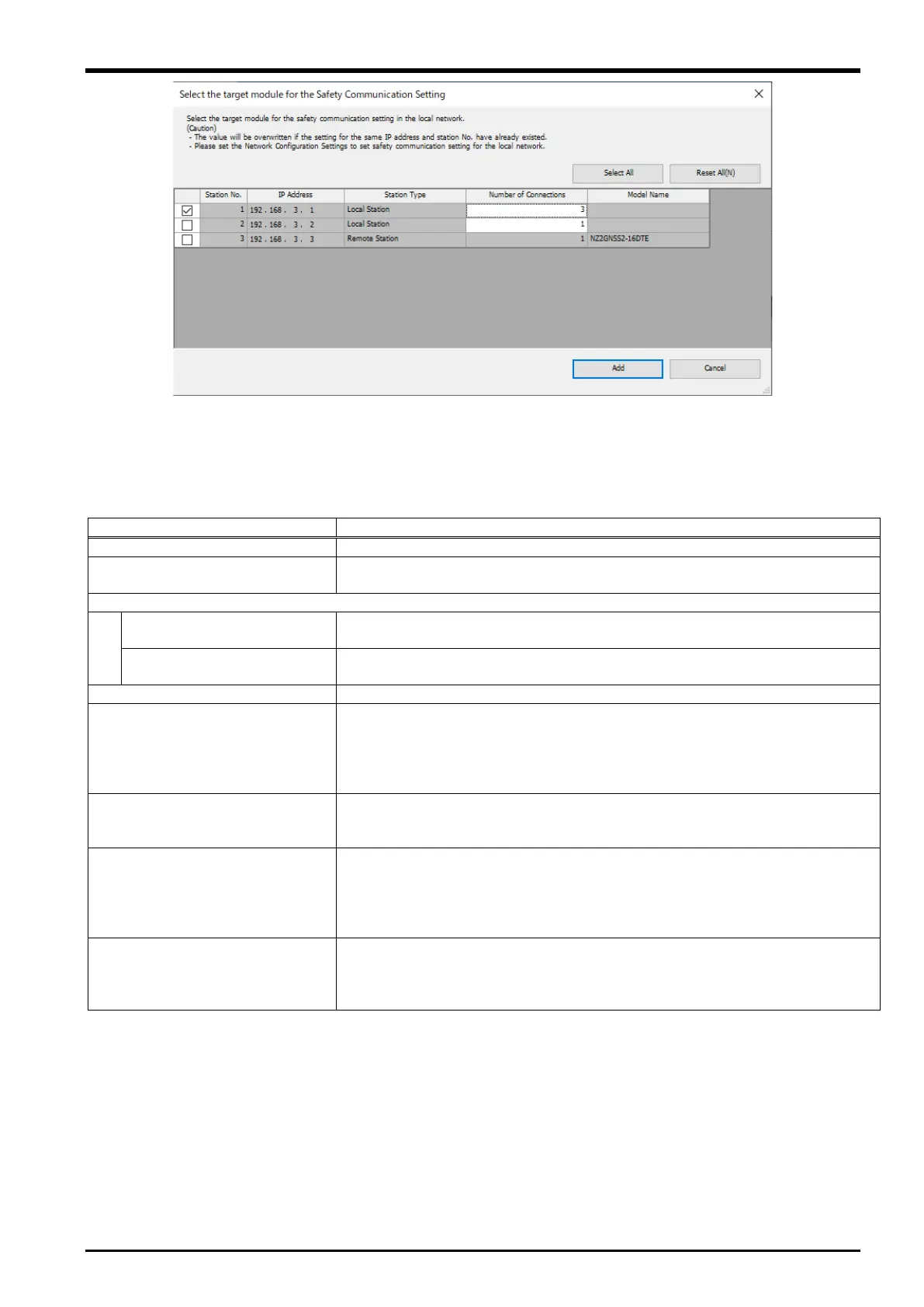

Table 3-4 Safety communication settings (master station)

Communication Destination

Select the target module for the

Safety Communication Setting

Select local stations (robot controllers) used for safety communication.

Communication Destination

(Note 1)

Set the numbers (multiple CPU system) of the robot CPU modules

(R16RTCPU) for the robot controllers that perform safety communication.

Active (safety connection established from the own station)

Sending Interval Monitoring Time

Set a value that satisfies the conditions shown in "4.7.2 Transmission

interval monitoring time" according to the system configuration. If the error

H8254 (Safety comm. timeout) is detected, review the setting value. When

the transmission interval monitoring time is changed, change the conditions

of the safety refresh monitoring time (master station-side settings) as well.

Safety Refresh Monitoring Time

Set a value that satisfies the conditions shown in "4.7.3 Safety refresh

monitoring time" according to the system configuration. If the error H8252

(Safety comm. timeout) is detected, review the setting value.

Receive Data Storage Device

Set a device that stores the data received from the robot controller

performing safety communication. When setting the number of device

points, set "16" for bit devices, and "1" for word devices. The SCNO outputs

of the robot controller are stored in the first four points of the specified

Set a device that stores the data sent to the robot controller performing

safety communication. When setting the number of device points, set "16"

for bit devices, and "1" for word devices. The first eight points of the

specified device are sent as the SCNI inputs of the robot controller.

Note 1: Even when setting the CR860-R, set "CR800-R" as the communication destination.

3.4 Creating a Safety Program

Create a safety program in the safety CPU module for safety control of the system. Refer to the following manuals.

□ MELSEC iQ-R CPU Module User's Manual (Startup) (SH-081263ENG)

□ MELSEC iQ-R CPU Module User's Manual (Application) (SH-081264ENG)

□ MELSEC iQ-R Safety Application Guide (SH-081538ENG)

Loading...

Loading...