114

Function assignment of external

terminal and control

4.10.8 Remote output function (REM signal, Pr. 495 to Pr. 497)

You can utilize the on/off of the inverter's output signals instead of the remote output terminal of the

programmable logic controller.

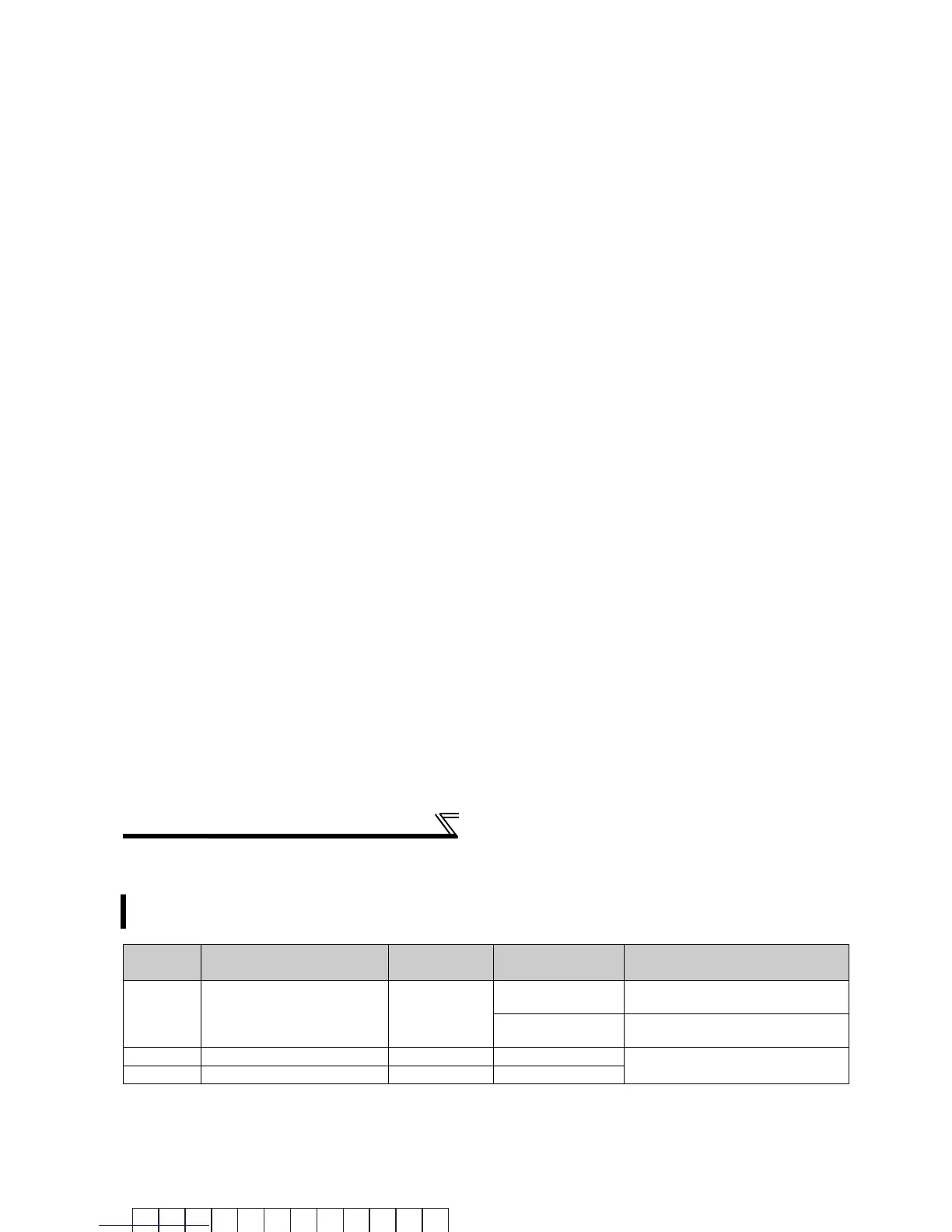

Parameter

Number

Name Initial Value Setting Range Description

495 Remote output selection 0

0

Remote output data clear at powering

off

1

Remote output data held at powering

off

496 * Remote output data 1 0 0 to 4095

Refer to the following diagram.

497 * Remote output data 2 0 0 to 4095

The above parameters can be set when Pr. 160 User group read selection = "0". (Refer to page 156)

* The above parameters allow its setting to be changed during operation in any operation mode even if "0" (initial value) is set in

Pr. 77 Parameter write selection.

<Remote output data>

Pr. 496

Pr. 497

*1 As desired

*2 Y0 to Y6 are available only when the extension output option (FR-

A7AY) is fitted

*3 RA1 to RA3 are available only when the relay output option (FR-A7AR)

is fitted

⋅ The output terminal can be turned on/off depending

on the Pr. 496 or Pr. 497 setting. The remote output

selection can be controlled on/off by computer link

communication from the PU connector or RS-485

port or by communication from the communication

option.

⋅ Set "96" (positive logic) or "196" (negative logic) to

any of Pr. 190 to Pr. 196 (output terminal function

selection), and assign the remote output (REM)

signal to the terminal used for remote output,

⋅ When you refer to the left diagram and set 1 to the

terminal bit (terminal where the REM signal has

been assigned) of Pr. 496 or Pr. 497, the output

terminal turns on (off for negative logic). By setting

0, the output terminal turns off (on for negative

logic).

Example)When "96" (positive logic) is set to Pr. 190 RUN terminal function selection and "1" (H01) is set to Pr. 496,

the terminal RUN turns on.

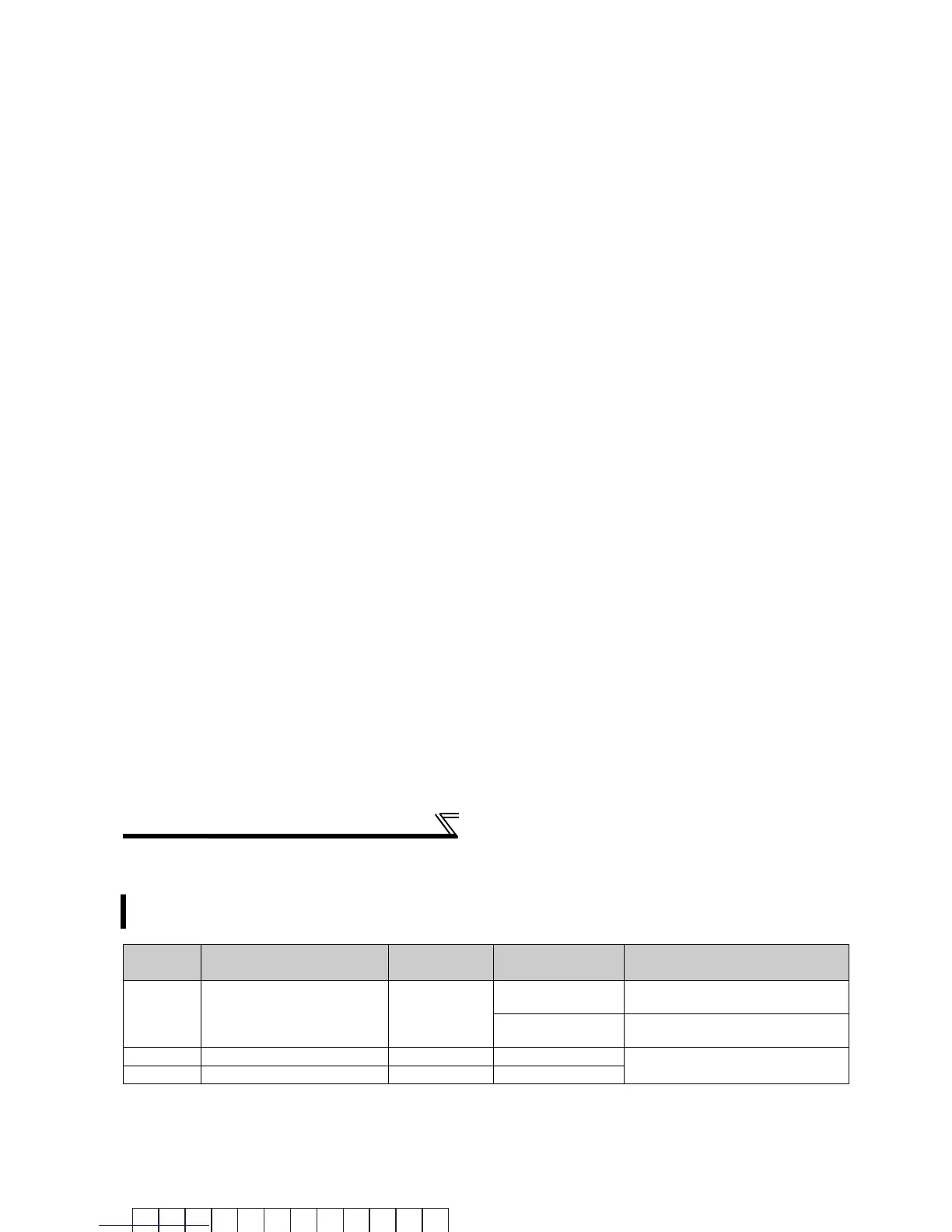

ON/OFF example for positive logic

⋅ When Pr. 495 = "0" (initial value), performing a power

supply reset (including a power failure) clears the REM

signal output. (The ON/OFF states of the terminals are

as set in Pr. 190 to Pr. 196.) The Pr. 496 and Pr. 497

settings are also "0".

When Pr. 495 = "1", the remote output data before power

supply-off is stored into the EEPROM, so the signal

output at power recovery is the same as before power

supply-off. However, it is not stored when the inverter is

reset (terminal reset, reset request through

communication).

(See the chart on the left)

REMARKS

⋅ The output terminal where the REM signal is not assigned using any of Pr. 190 to Pr. 196 does not turn on/off if 0/1 is set to the

terminal bit of Pr. 496 or Pr. 497 . (It turns on/off with the assigned function.)

⋅ When the inverter is reset (terminal reset, reset request through communication), Pr. 496 and Pr. 497 values turn to "0". When Pr.

495 = "1", however, they are the settings at power supply-off. (The settings are stored at power supply-off.)

CAUTION

⋅ When Pr. 495 = "1"(remote output data retention even at powering off), take such a step as to connect R1/L11, S1/L21 and P/+,

N/- to ensure that control power will be retained to some degree. If you do not take such a step, the output signals provided after

power-on are not guaranteed.

♦ Parameters referred to ♦

⋅ Pr. 190 to Pr. 196 (output terminal function selection) Refer to page 107

b11 b0

ABC1

ABC2

*1

*1

*1

*1

*1

FU

OL

IPF

SU

RUN

b11 b0

Y5 *2

Y6 *2

RA1 *3

RA2 *3

RA3 *3

*1

*1

Y4 *2

Y3 *2

Y2 *2

Y1 *2

Y0 *2

Power

supply

Power

supply

OFF OFF

ONOFF

REMREM

REM signal clear REM signal held

Inverter

reset time

(about 1s)

Pr.495 = 0

Pr.495 = 1

Loading...

Loading...