Set up the robot arm Installation

3 - 18

3.3.2 Set up the SCARA robot

RH-6SDH/12SDH/20SDH and RH-6SQH/12SDH/20SDH

The table below shows how to set up and fix the SCARA robots RH-6SDH/12SDH/20SDH and

RH-6SQH/12SQH/20SQH.

The base area of the robot arm has been leveled by machine.

If the bas area is too uneven then this may result in robot arm malfunctions.

Fix the robot arm above the assembly boreholes on the four outer edges of the base area using

the supplies Allen head screws.

Align the robot arm horizontally.

The average surface finish of the assembly surface should be Ra = 6.3

μ

m. If the surface is too

rough then this may result in deviations in the position of the robot arm.

To avoid position deviations, the peripheral equipment that the robot accesses as well as the robot

arm itself should be installed on a common assembly platform/area.

The base area must be designed so that no distortion can occur, even from the loads and vibrations

emanating from the robot itself.

Only remove the transport locks, suspensions and supporting brackets after setting up the robot arm.

High loads and strains occur on the base area when operating the robot at high speeds. Make

sure that the base area is suitable for the high forces and moments, as listed in Tab. 3-5.

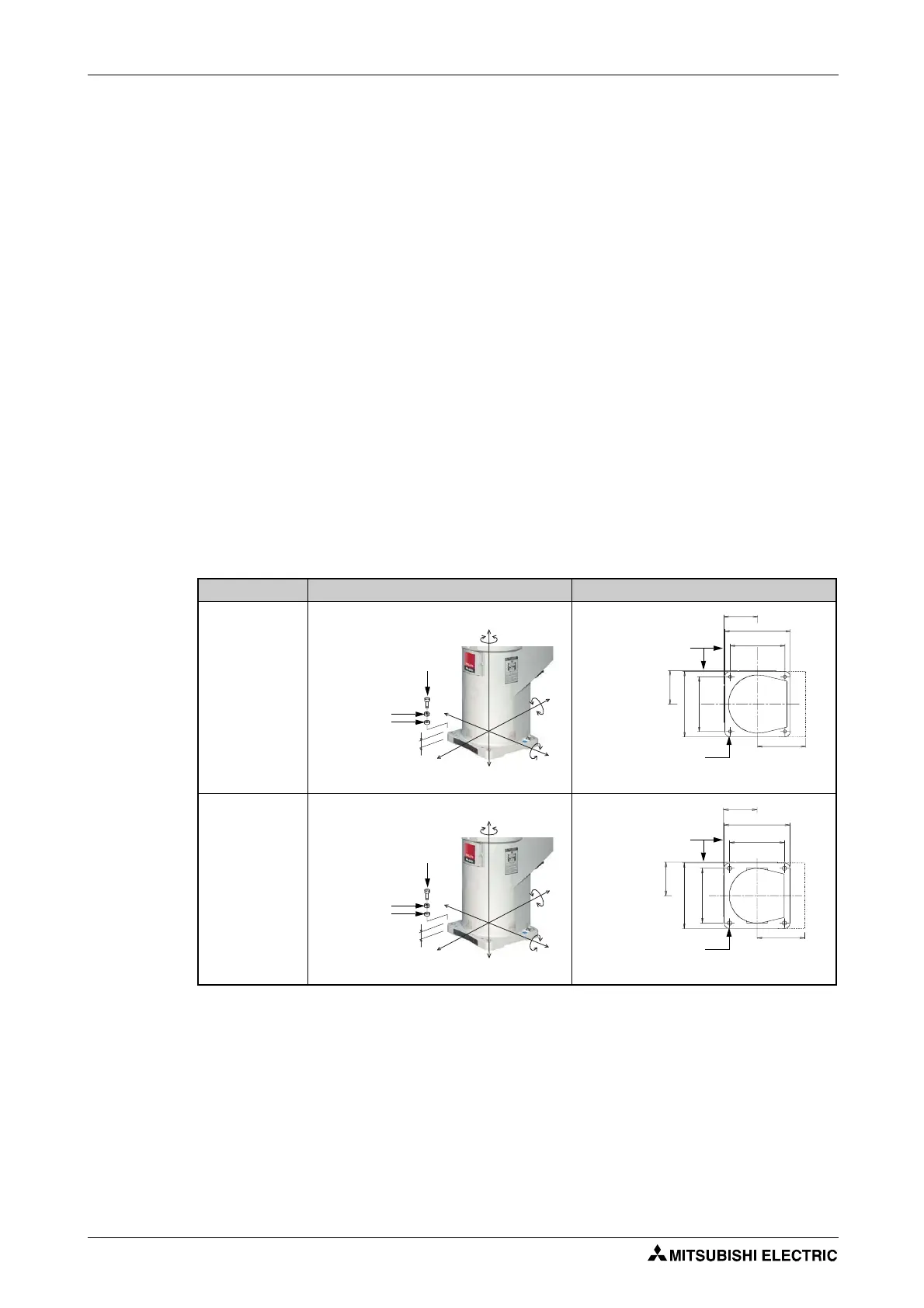

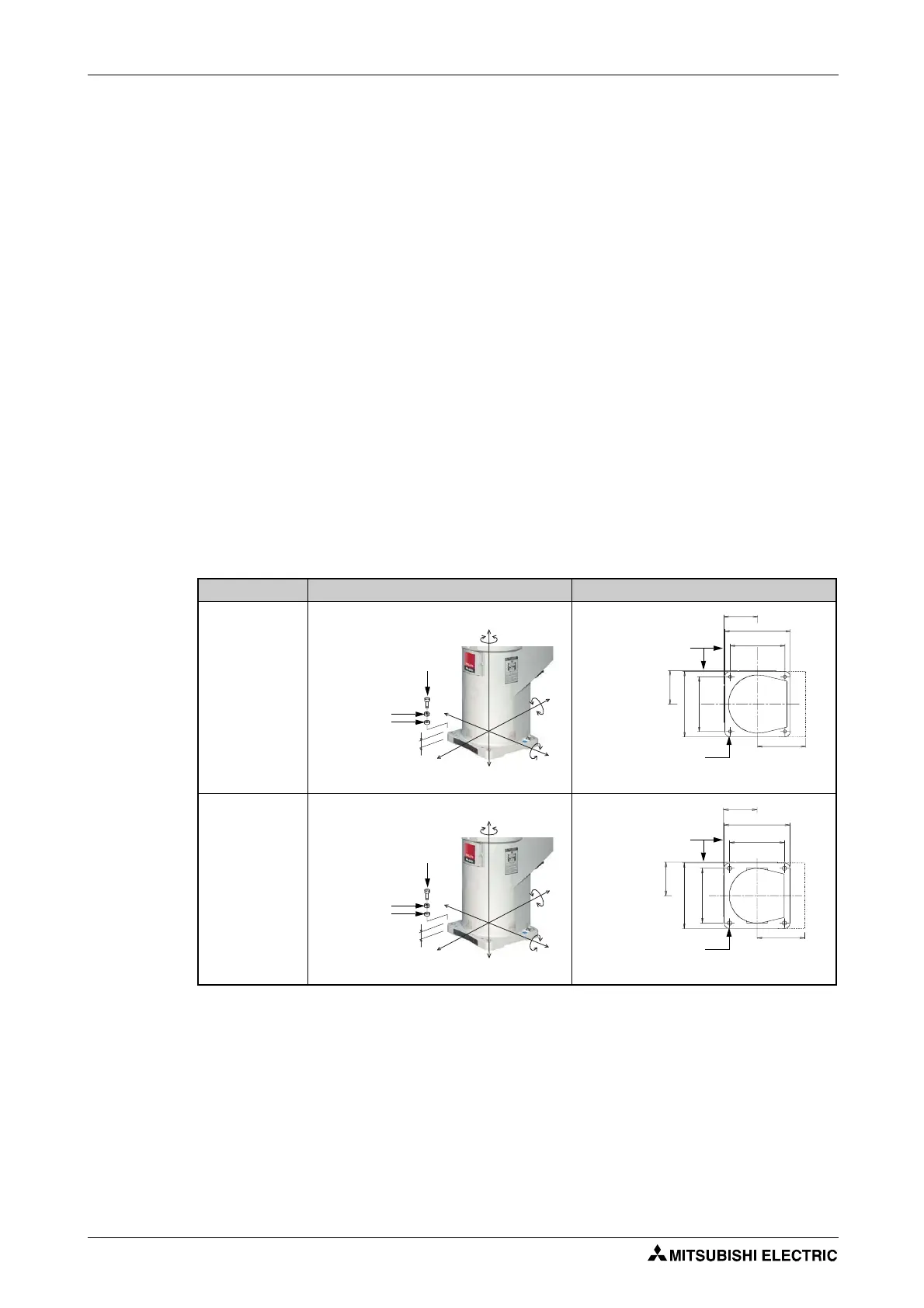

Robot arm Fixture View from below

RH-6SDH,

RH-6SQH

R001447E R001448E

RH-12SDH/20SDH,

RH-12SQH/20SQH

R001447E R001449E

Tab. 3-4: Set up the robot arm

20

㧲

㧴

㧲

㨂

㧲

㧴

㧲

㧴

㧲

㧴

㧹

㧸

㧹

㧸

㧲

㨂

㧹

㨀

Fixing

screws (4)

M8 x 40 Allen screw

Snap ring

Washer

Installation side

(standard)

4-9 fixing boreholes

Maintenance

clearance

20

㧲

㧴

㧲

㨂

㧲

㧴

㧲

㧴

㧲

㧴

㧹

㧸

㧹

㧸

㧲

㨂

㧹

㨀

Fixing

screws (4)

M12 x 45 Allen screw

Snap ring

Washer

Installation side

(standard)

4-16 fixing boreholes

Maintenance

clearance

Loading...

Loading...