Loading...

Loading...

Do you have a question about the Mitsubishi 4G9 and is the answer not in the manual?

| Brand | Mitsubishi |

|---|---|

| Model | 4G9 |

| Category | Engine |

| Language | English |

Details on engine specifications, including service, rework, torque, and material requirements.

List and description of specialized tools required for engine service procedures.

Procedures for removal and installation of alternator and ignition system components.

Removal, installation, inspection, and adjustment procedures for the timing belt system.

Procedures for removal and installation of fuel and emission control system components.

Procedures for removal and installation of intake and exhaust manifolds for various models.

Procedures for removal and installation of the water pump and associated hoses.

Procedures for removal, installation, inspection, and adjustment of rocker arms and camshafts.

Procedures for cylinder head and valve removal, installation, inspection, and handling.

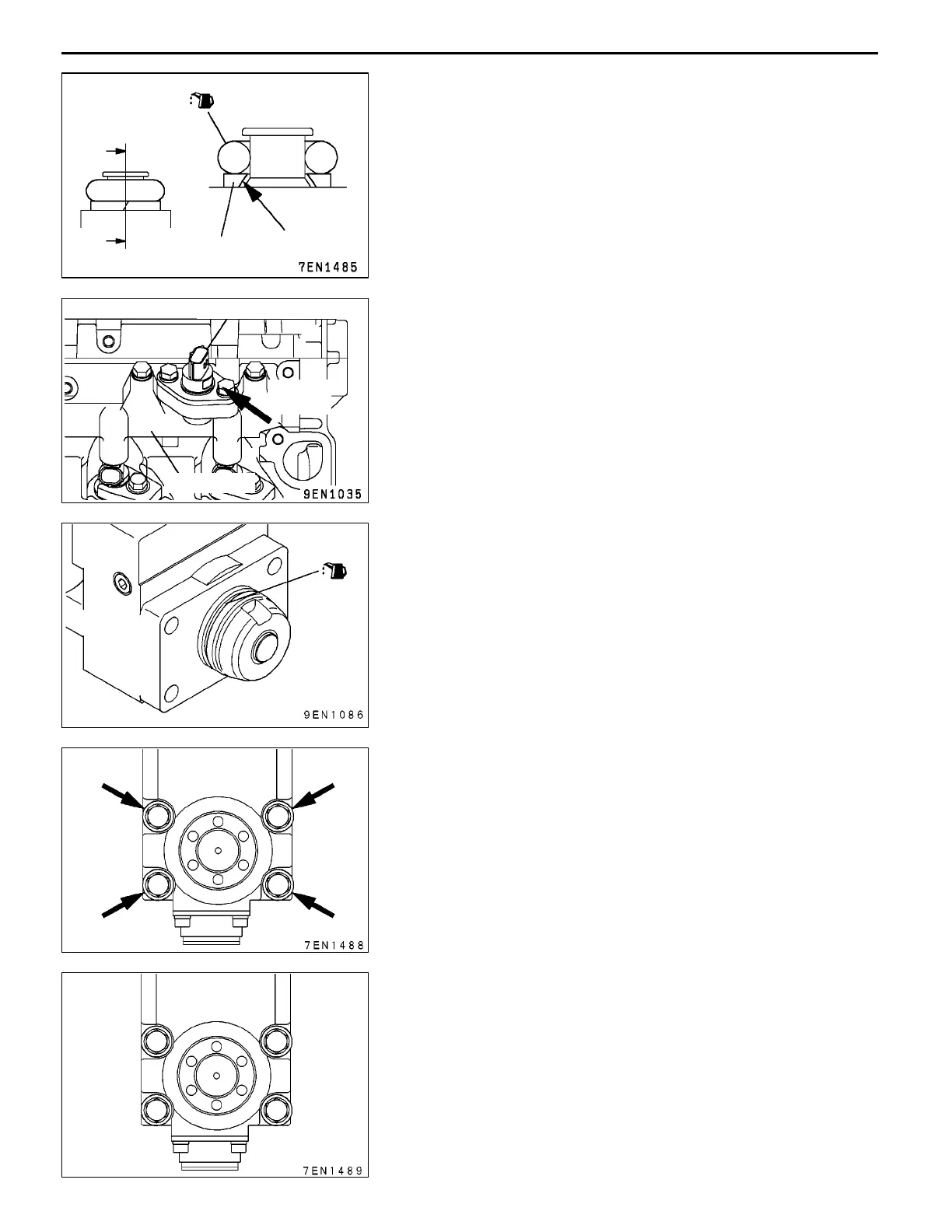

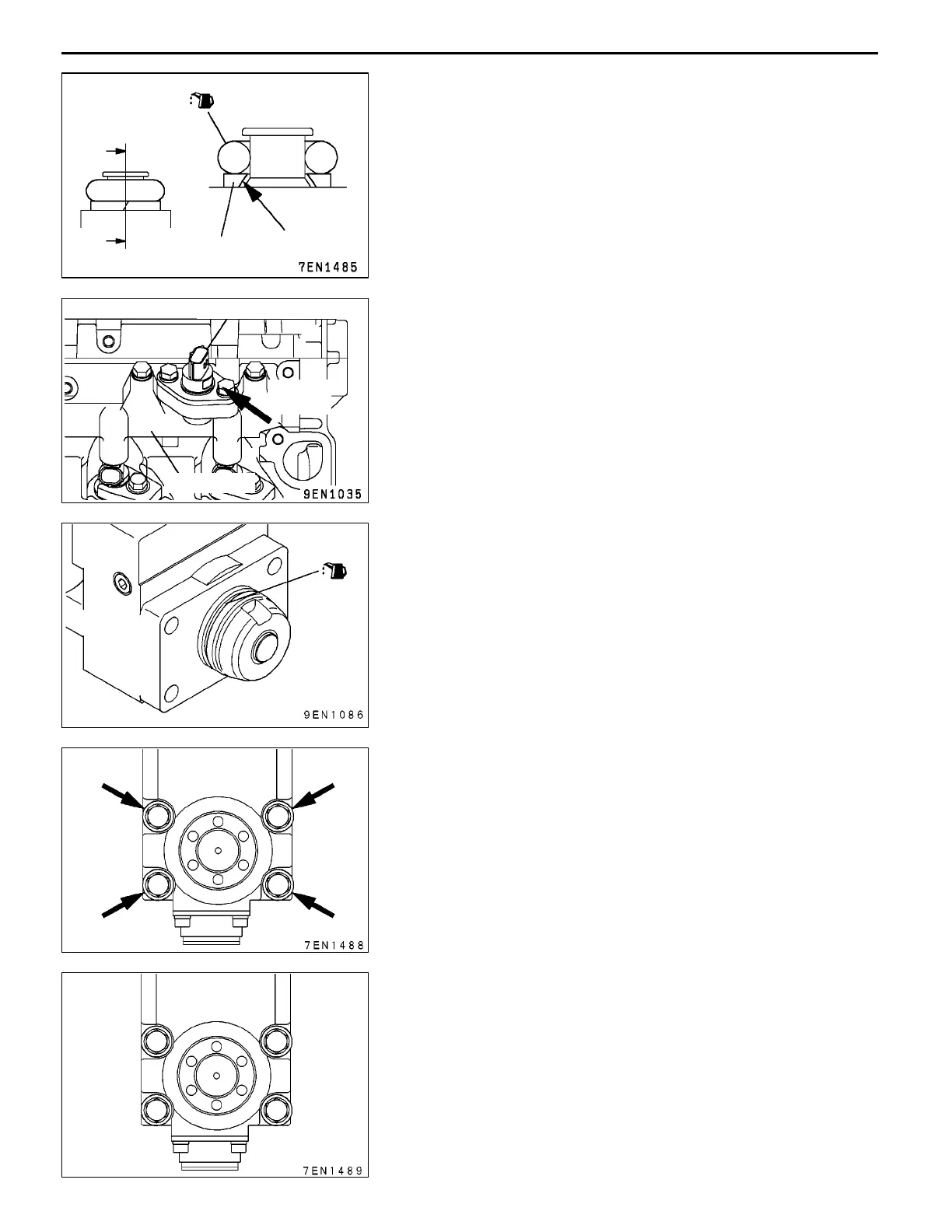

Procedures for removal, installation, and inspection of the front case and oil pump.

Procedures for removal, installation, and inspection of pistons and connecting rods.

Procedures for removal, installation, and inspection of crankshaft, cylinder block, and related components.