WELDING

BASE OF BODY REPAIR

9-11

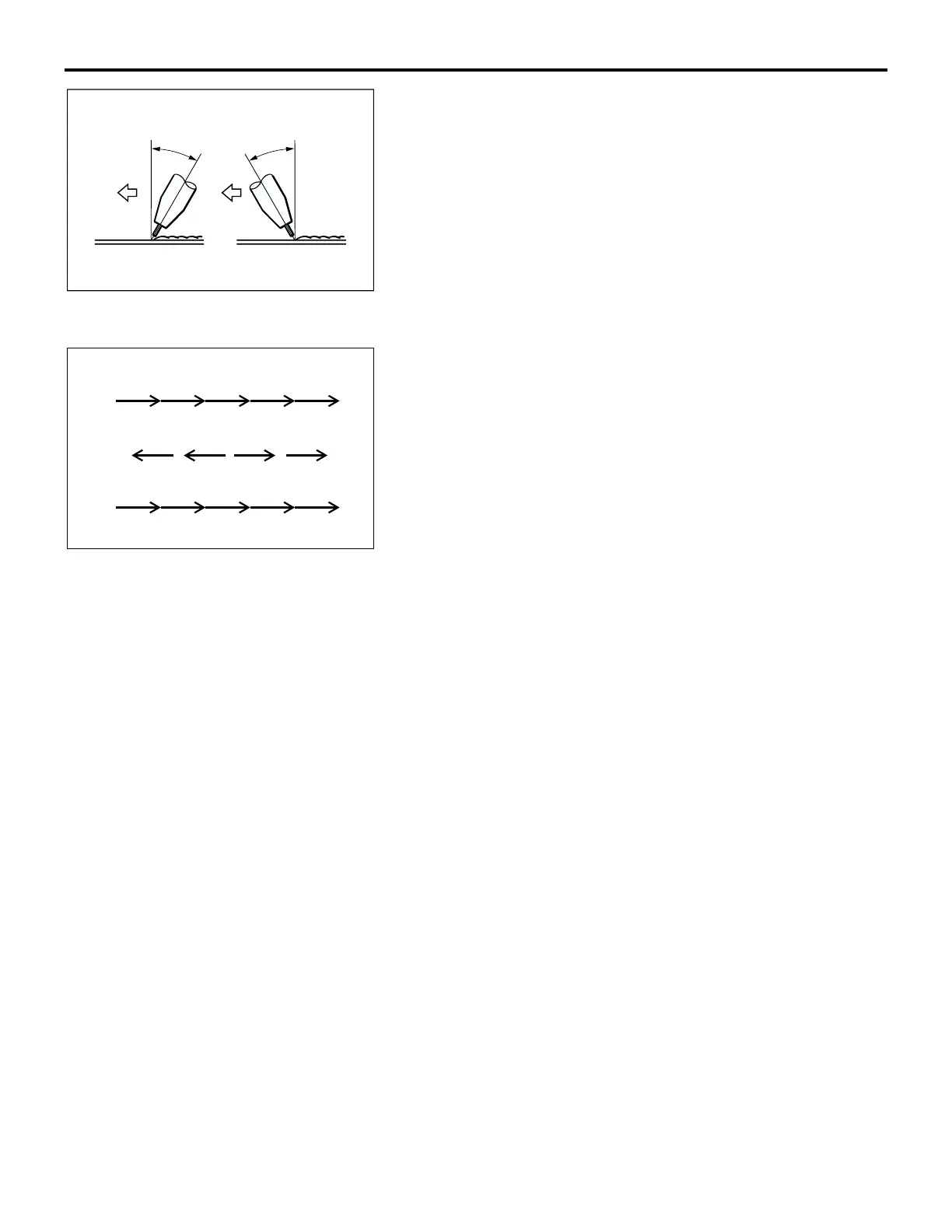

The angle of the torch should be 15 degree angle to 30 degree

angle for either technique, and the tip should be maintained at

a distance of 6 to 10 mm (0.2 to 0.4 inch) from the surface

being welded.

.

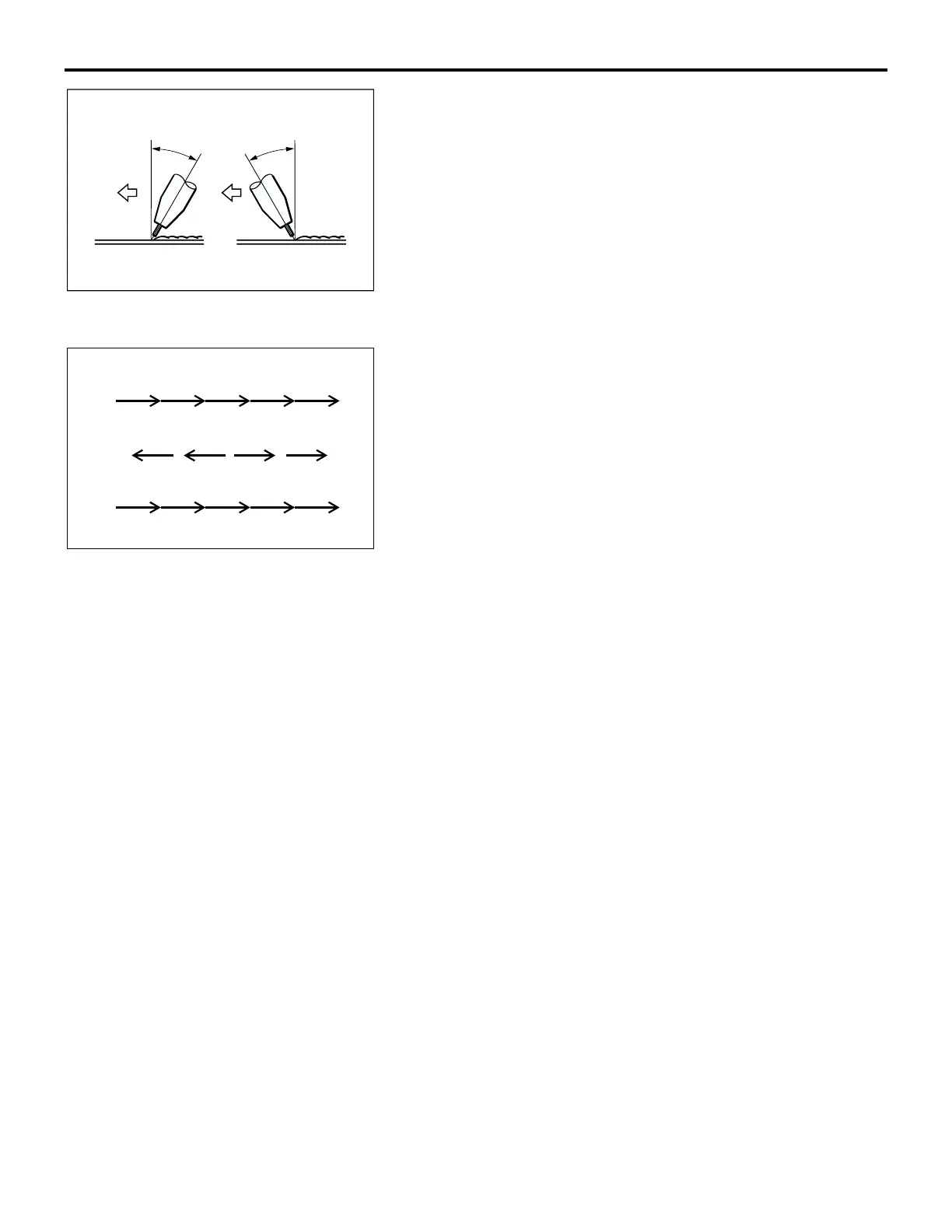

Preventing warping

1. Backhand technique

Because the direction for each weld pass and that for the

fusion progression are opposite, the residual stress is

evenly distributed.

2. Symmetrical technique

Because the welds are made in symmetrical positions in

relation to the centre of the joint, the residual stress is also

symmetrical.

3. "Stepping stone" technique

Because the welds are made at random positions, the

residual stress is the most evenly distributed; however, the

possibility of flaws at the starting and stopping points is rela-

tively high.

NOTES REGARDING MIG WELDING

Note the following notes regarding MIG welding.

1. The surface to be welded must be perfectly

clean; be sure to remove any non-conductive

paint.

2. If the end of the wire forms into a ball, it will

adversely affect the formation of the arc; cut the

end off with a pair of wire snips or a similar tool.

3. Select a welding current to match the thickness of

the panels being welded.

4. For continuous welding, maintain a constant weld

speed and keep both the height and the width of

the bead constant.

In addition, the tack welding pitch and the welding

bead should be shorter as the thickness of the

panels being welded decreases.

OTHER TYPES OF WELDING

M4090004000013

BRAZING

In brazing, a filler metal is melted into the joint of the

panels to be welded at a comparatively low tempera-

ture to fuse them together without melting the panels

themselves. In other words, through the aid of a flux

and because of the capillarity phenomenon, the mol-

ten filler metal will flow into the joint between the two

panels which are in contact with each other and

spread along the metal surfaces. When this molten

filler metal cools and solidifies, it will from a strong

joint of the two panels. Note that, if two panels of dif-

ferent kinds of metal are brazed, the electrolysis gen-

erated between the two metals will cause moisture to

from, which will result in corrosion.

Panels should not be connected together by brazing

at any place except those places indicated. The fol-

lowing materials (filler metals) are usually used for

brazing.

1. Brass filler metal (brass solder)

Brass filler metal is an alloy consisting of 60%

copper and 40% zinc with a melting temperature

of approximately 850 to 1,050°C (1,562 to

1,922°F), and it is the most commonly used braz-

ing filler metal used for body repair.

The filler metal itself is coated with flux to facili-

tate penetration between the panels to be joined.

AB200042

15˚ - 30˚ 15˚ - 30˚

FOREHAND

TECHNIQUE

BACKHAND

TECHNIQUE

AB

AB200043

AB

ANTI-WARP WELDING TECHNIQUES

1.

2.

3.

BACKHAND TECHNIQUE

SYMMETRICAL TECHNIQUE

"STEPPING STONE" TECHNIQUE

54321

54321

4321

Loading...

Loading...