BODY REPAIR

BASE OF BODY REPAIR

9-28

FRAME REPAIR PROCEDURES

M4090014000014

The frame is subjected to the following types of

loads.

• Vertical loads... Vertical loads may occur either

while stopped or during travel.

• Lateral (horizontal) loads... This type of loads

occurs during turning, start-off and braking.

• Torsional loads... Torsional loads occur while

traveling on roads with poor surface conditions.

These various types of loads are compounded under

various conditions, and are applied to the frame.

As a result, it is important, before attempting to repair

the frame, to carefully observe the shape of the dam-

aged part and to in that way fully understand the

cause of the damage.

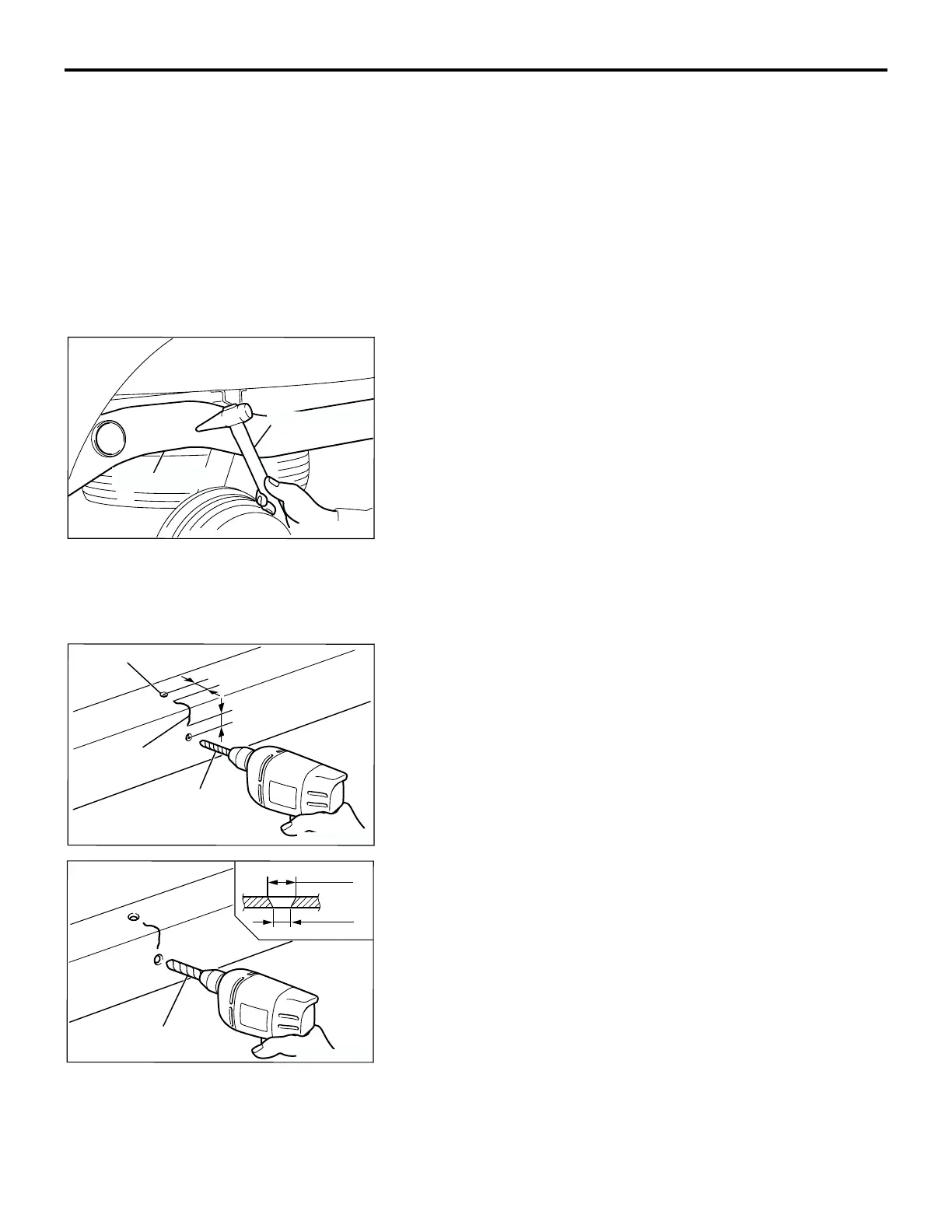

CHECKING FOR FRAME CRACKING OR

FLANKING

Check, by using a test hammer, for flaking or cracking of the

welded surface of the sidemembers, crossmembers and brack-

ets.

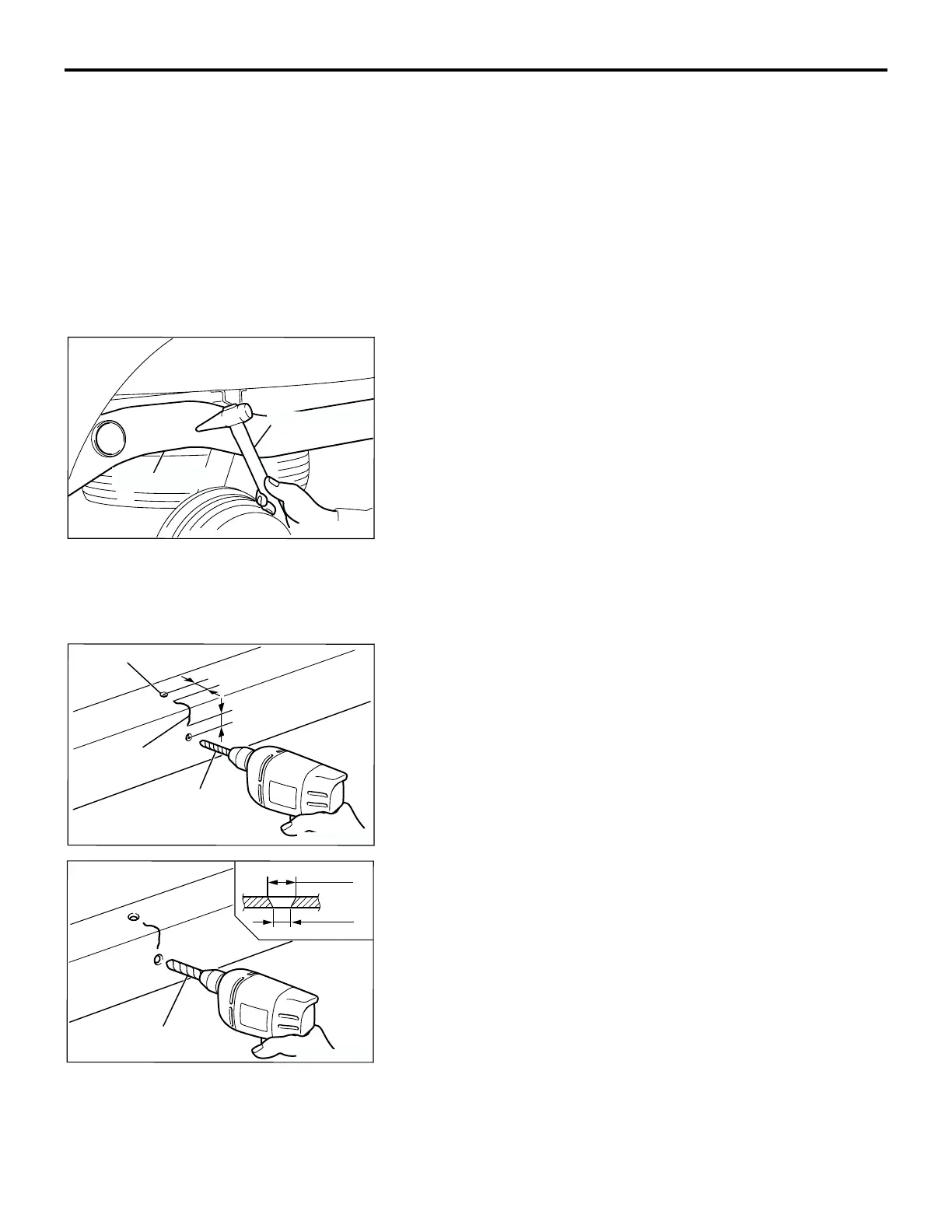

REPAIRING CRACKS

If the check reveals a crack(s) in the frame, repair as described

bellow.

1. Remove the components near the crack.

2. Make φ 6 - 8 mm (0.2 - 0.3 inch) holes (to prevent further

cracking), by using a drill, at points 7 - 8 mm (0.3 inch) from

the crack ends.

3. Use a φ 10 - 12 mm (0.4 - 0.5 inch) drill to bevel the hole

openings.

AB200127

AB

TEST HAMMER

SIDEMEMBER

AB200128

CRACK-STOP HOLE

CRACK

A

A

Ø6 - 8 mm

(0.2 - 0.3 in)

A : 7 - 8 mm (0.3in)

AB

AB200129

AB

Ø10 - 12 mm

(0.4 - 0.5 in)

Ø10 - 12 mm (0.4 - 0.5 in)

Ø6 - 8 mm

(0.2 - 0.3 in)

Loading...

Loading...