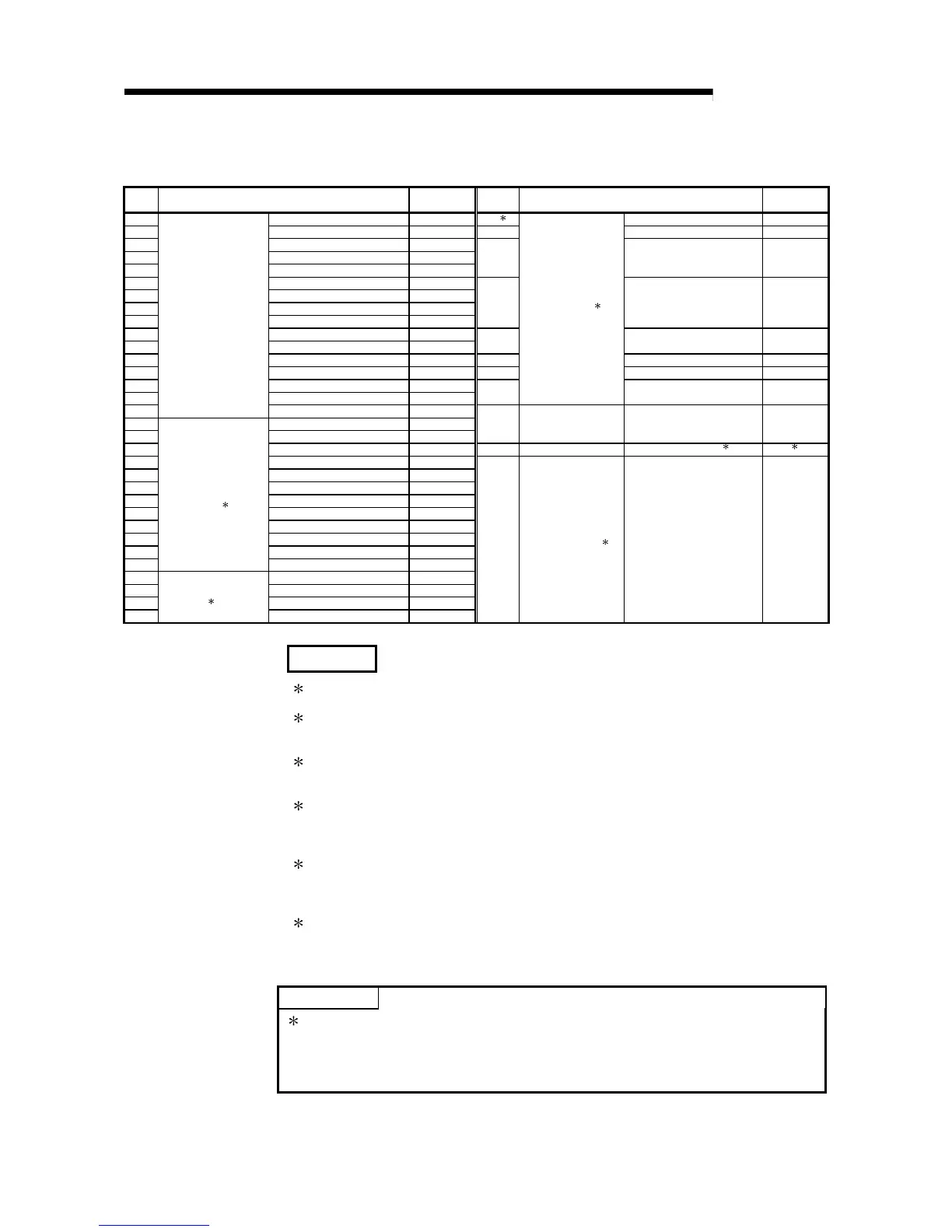

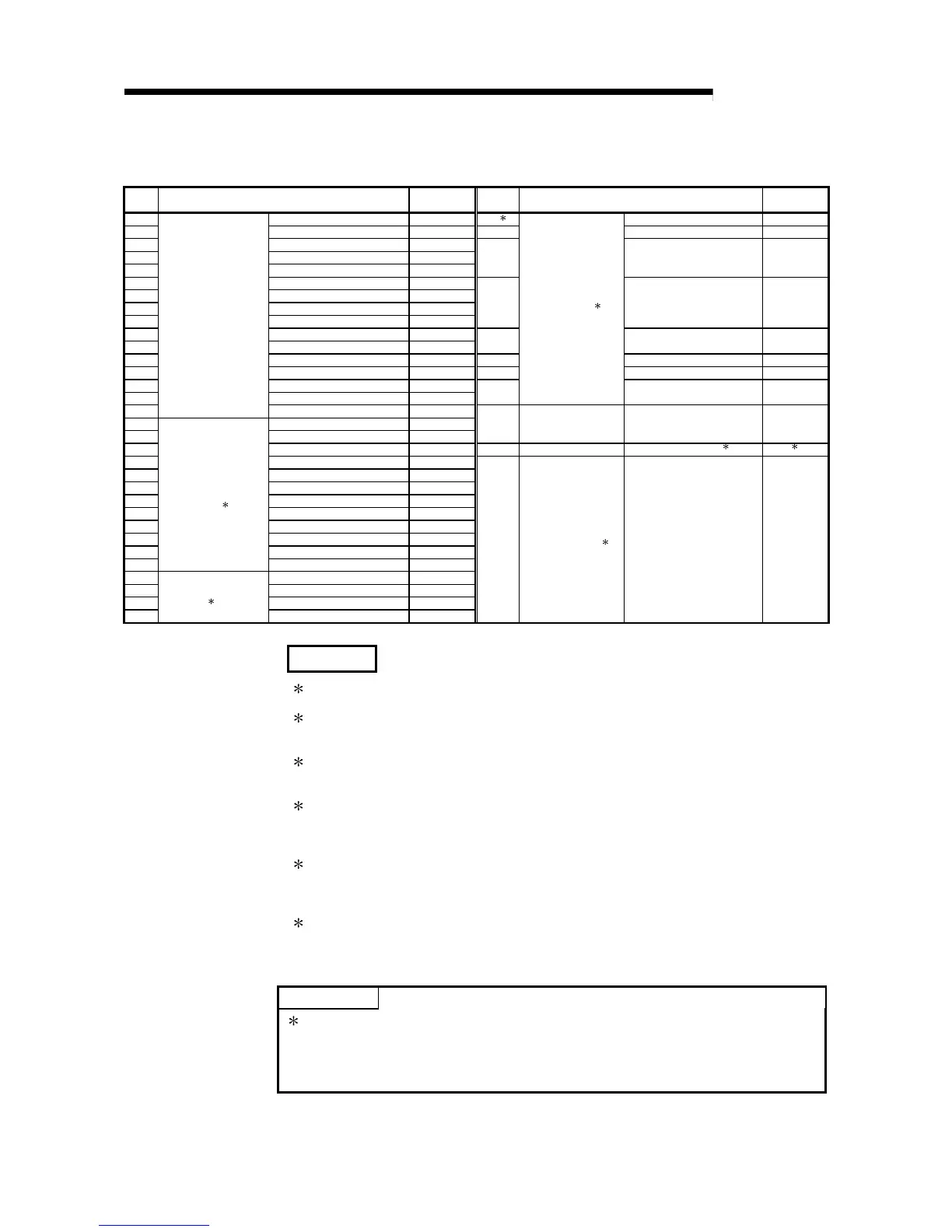

eration 1

I1 2nd point 238 I33 Empty ——

I2 3rd point 239

I3 4th point 240

I4 5th point 241

I34

UNIT VERIFY ERR.

FUSE BREAK OFF

SP. UNIT ERROR

2

I5 6th point 242

I6 7th point 243

I7 8th point 244

I8 9th point 245

I35

OPERATION ERROR

SFCP OPE. ERROR

SFCP ECE. ERROR

EX. POWER OFF

3

I9 10th point 246

I10 11th point 247

I36

ICM. OPE ERROR

FILE OPE. ERROR

4

I11 12th point 248 I37 Empty ——

I12 13th point 249 I38 PRG. TIME OVER 5

I13 14th point 250

I14 15th point 251

I39

Error factor

4

CHK instruction execution

Anunciator detection

6

I15

QI60/A1SI61

interrupt module

factor

16th point 252

I16 1st point 224

I17 2nd point 225

I40 to

I48

—— Empty ——

I18 3rd point 226 I49 Internal timer factor 0, 2 to 1.0mg

5

7

I19 4th point 227

I20 5th point 228

I21 6th point 229

I22 7th point 230

I23 8th point 231

I24 9th point 232

I25 10th point 234

I26 11th point 235

I27

Sequence start

generator module

factor

1

12th point 236

I28 100ms 256

I29 40ms 255

I30 20ms 254

I31

Internal timer factor

2

10ms 253

I50 to

I255

Intelligent function

module factor

6

Specifies which intelligent

function module is used

with parameters.

18 to 223

REMARK

1 : 1st to 12th points are allocated in order, beginning from the sequence start

generator module installed closest to the High Performance model QCPU.

2 : The internal times shown are the default setting times.

These times can be designated in 0.5 ms units through a 0.5 to 1000 ms range

set at the "PLC system" tab screen in the “(PLC) Parameter" dialog box.

3 : When an error interruption with "I32 (error that stops operation)" occurs, the

High Performance model QCPU is not stopped until I32 processing is

completed.

4 : Execution of error interruptions is prohibited for the interrupt pointer Nos. I32 to

I39 when the power is turned on and during a High Performance model QCPU

reset. When using interrupt pointer Nos. I32 to I39, set the interruption

permitted status by using the IMASK instruction.

5 : Set the time-out period of the internal timer by choosing "PLC system" -

"System interrupt setting" - "High speed interrupt setting" on the PLC parameter

screen.

Set it in the setting range 0.2 to 1.0ms in 0.1ms increments.

6 : To use the intelligent function module interrupt, the intelligent function module

setting (interrupt points setting) is required at the "PLC system" tab screen in

the “(PLC) Parameter" dialog box.

(For the interrupts from the intelligent function module, see Section 8.2.1.)

POINT

7: When you have set I49 in the PLC parameters, do not execute other interrupt

programs (I0 to I48, I50 to I255) and fixed-cycle programs. If any fixed-cycle

program or like is run, the interrupt program using I49 cannot be executed at

the preset interrupt cycle intervals.

Loading...

Loading...