9-42

9-7 Special Objects

OMNUC G5-series AC Servomotors and Servo Drives User’s Manual (with Built-in EtherCAT Communications)

9

Details on Servo Parameter Objects

*1. When load characteristic estimation is disabled, inertial ratio updating is also disabled, even if the

latter is set to be updated with the estimation result. When torque compensation is updated with the

estimation result, load characteristic estimation is disabled.

Precautions for Safe Use

This object must be set in units of bits. Users must be fully aware that proper operation of your

system is not guaranteed, if you have incorrect object settings. Pay a particular attention when you

set them.

Reference

Procedure to Set the Object Bit by Bit

Follow these steps and calculate the set values, when you make any setting other than 0.

(1) Confirm the least significant bit (LSB) in each set value.

E.g. LSB of Torque compensation function: 4

(2) Multiply the set value by 2 to the power of the bit number of the LSB.

E.g. To set the torque compensation to Friction compensation (small): The set value is 3.

The exponent is 4.

2

4

× 3 = 48

(3) Repeat Step (1) and (2) for all bit settings. Add all results and set the outcome to 3632 hex.

E.g. When all of the Load characteristic estimation, the Inertia ratio updating, the Rigidity

setting, and the Gain switch setting are enabled, the Torque compensation is set to

Friction compensation (small), and the Fixed object setting is set to a Fixed value:

2

0

× 1 + 2

2

× 1 + 2

4

× 3 + 2

7

× 1 + 2

8

× 1 + 2

9

× 2 = 1461

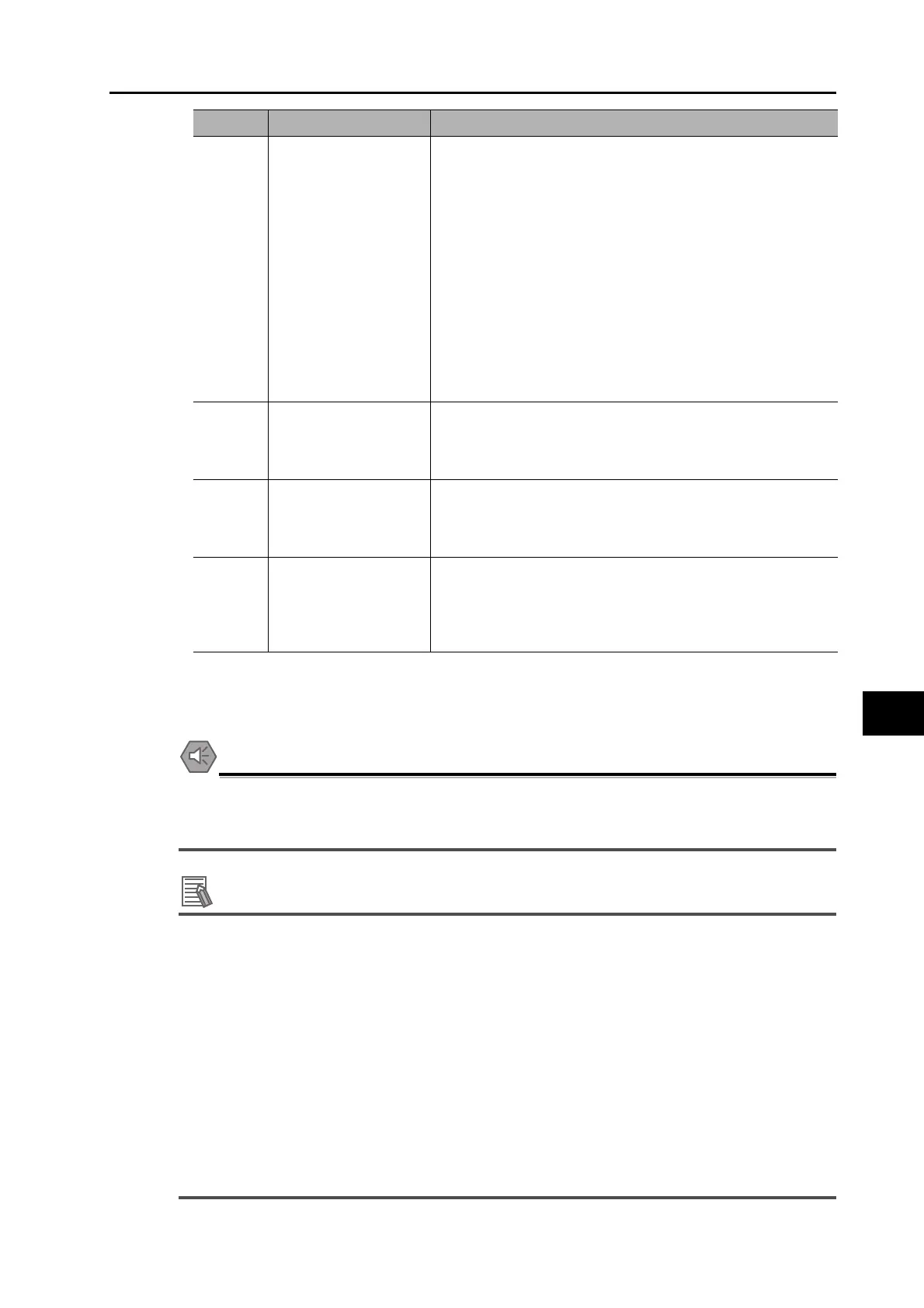

4 to 6 Torque compensation

Select whether to update three objects, Torque Command Value

Offset (3607 hex), Forward Direction Torque Offset (3608 hex),

and Reverse Direction Torque Offset (3609 hex), with the load

characteristic estimation result.

0: Use the present set value.

1: Disable the torque compensation. Clear the above three

objects to zero.

2: Vertical mode. Update 3607 hex. Clear 3608 hex and 3609

hex to zero.

3: Friction compensation (small). Update 3607 hex. Set a small

compensation to 3608 hex and 3609 hex.

4: Friction compensation (intermediate). Update 3607 hex. Set

an intermediate compensation in 3608 hex and 3609 hex.

5: Friction compensation (large). Update 3607 hex. Set a large

compensation in 3608 hex and 3609 hex.

7 Rigidity setting

Select to enable or disable the basic gain setting by the Realtime

Autotuning Machine Rigidity Setting (3003 hex).

0: Disable

1: Enable

8 Fixed object settings

Select whether to allow changes to the objects that normally are

fixed.

0: Use the present settings.

1: Set to fixed values.

9 to 10 Gain switch setting

Select the method to set the objects that relate to gain switching

while the realtime autotuning is enabled.

0: Use the present settings.

1: Disable gain switching.

2: Enable gain switching.

Bit Name Description

Loading...

Loading...