5.41

ENGINE

5

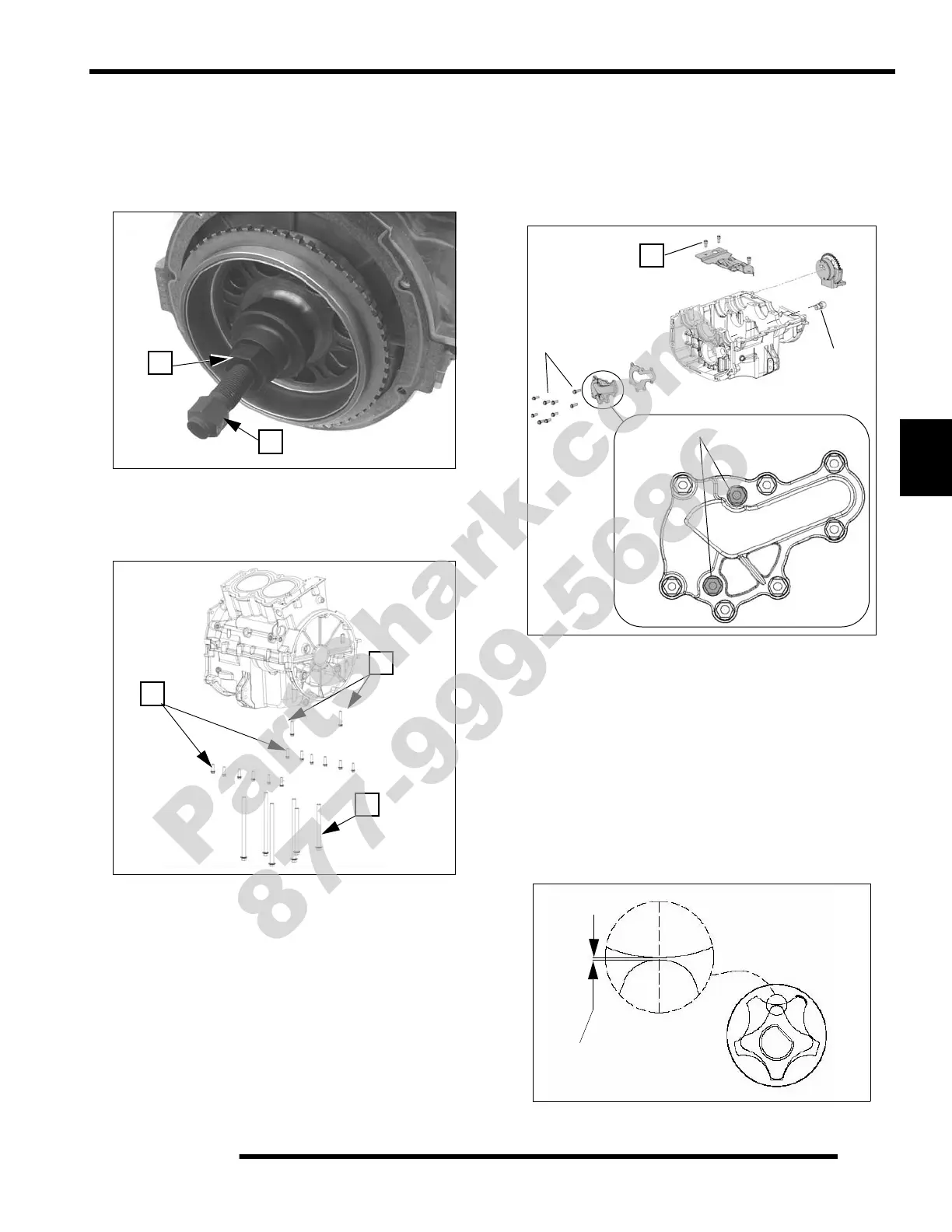

7. Fully install Flywheel Puller PA-49316 on threads of

flywheel (left hand thread - turn flywheel puller

COUNTERCLOCKWISE to install on flywheel).

8. Hold puller body (A) and tighten center bolt (B) to remove

flywheel.

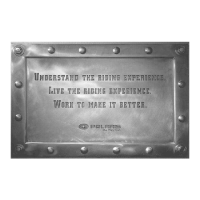

9. Loosen (12) outer crankcase bolts (C) evenly 1/2 turn, then

loosen (2) longer case bolts (D), then the (6) main crankcase

bolts (E). Remove all.

10. Tap lower crankcase in reinforced areas with a soft faced

hammer to loosen, then lift straight upward to remove.

Crankcase (Lower) / Oil Pump Disassembly

1. Remove oil pump cover plate screws. Note location of two

longer (M6x20) screws for assembly. These screws secure

the pump.

2. Remove three baffle plate screws (A) and plate.

3. Slide pump off mounting boss in crankcase.

4. Visually inspect pump rotors and drive gear for damage or

debris.

NOTE: Replace oil pump as an assembly and

pressure relief valve if debris has entered pump or if

pump damage is evident.

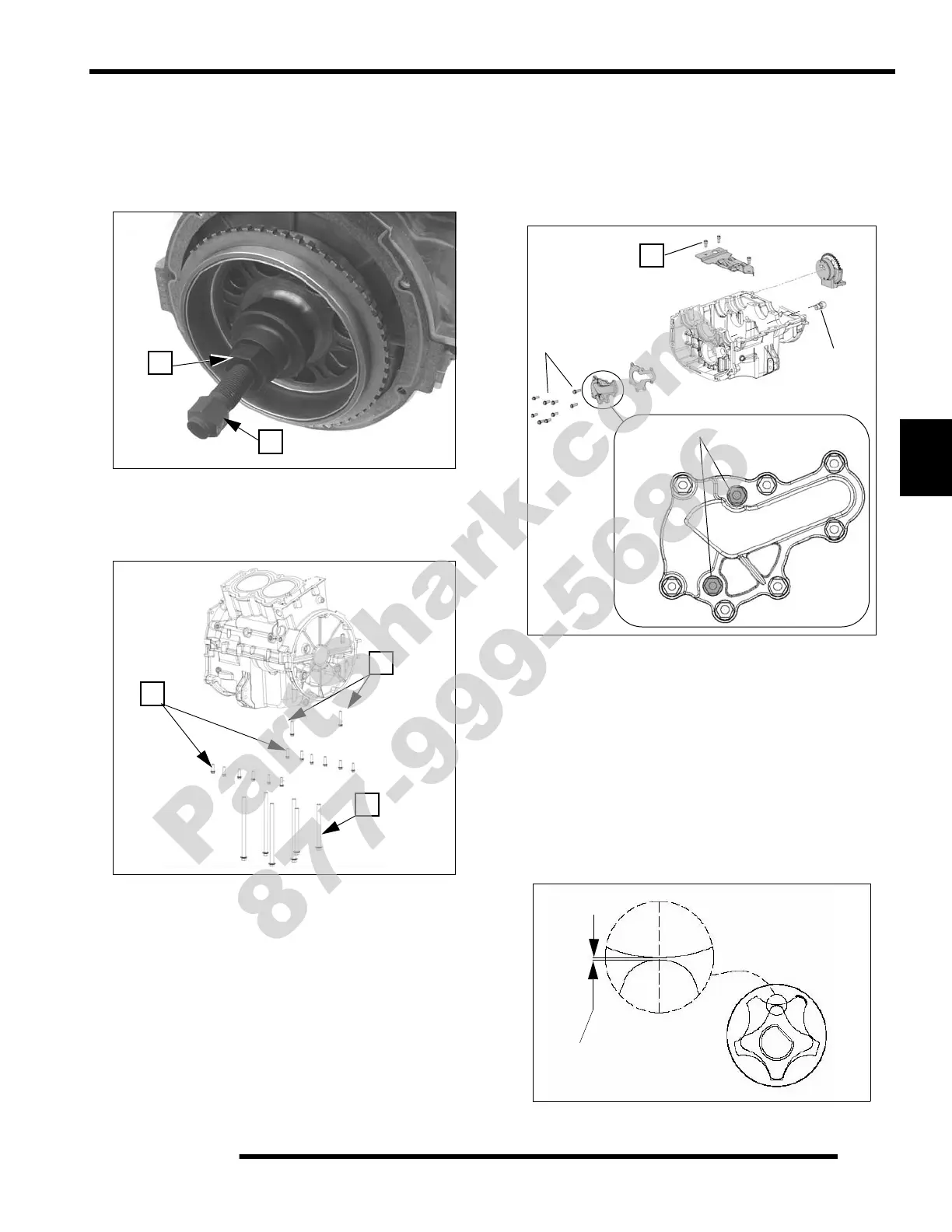

5. Rotate pump gear until rotors are positioned as shown

below. Use a feeler gauge to measure tip clearance.

Clearance should not exceed 0.006" (.15mm).

B

A

C

E

D

M6x20

96 lb-in. (12 Nm)

90 lb-in.

21 lb-ft.

(28 Nm)

A

(10 Nm)

M6x16

(all outer screws)

0.006” (0.15 mm)

PartShark.com

877-999-5686

Loading...

Loading...