5.46

ENGINE

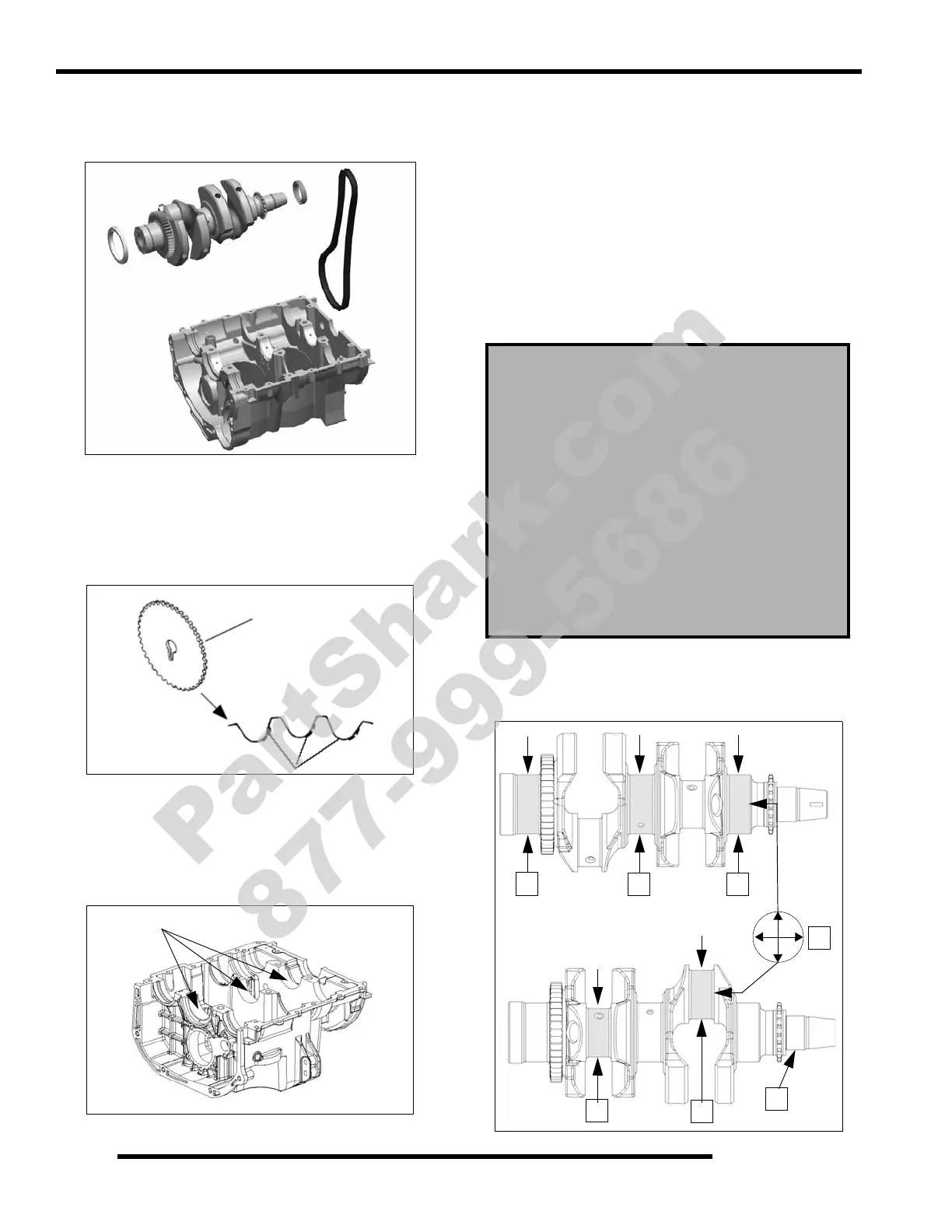

Crankshaft / Cam Chain Removal

1. Remove crankshaft with cam chain and end seals.

Cam Chain / Sprocket Inspection

1. Cam chain should be replaced if damage is evident or if

sprockets show visible signs of wear. Inspect drive and

driven sprocket as shown below.

Crankcase Inspection (Lower)

1. Remove main bearing inserts from lower crankcase half.

Replace the crankcase assembly if a bearing bore is galled

or if bearing inserts have rotated in the case.

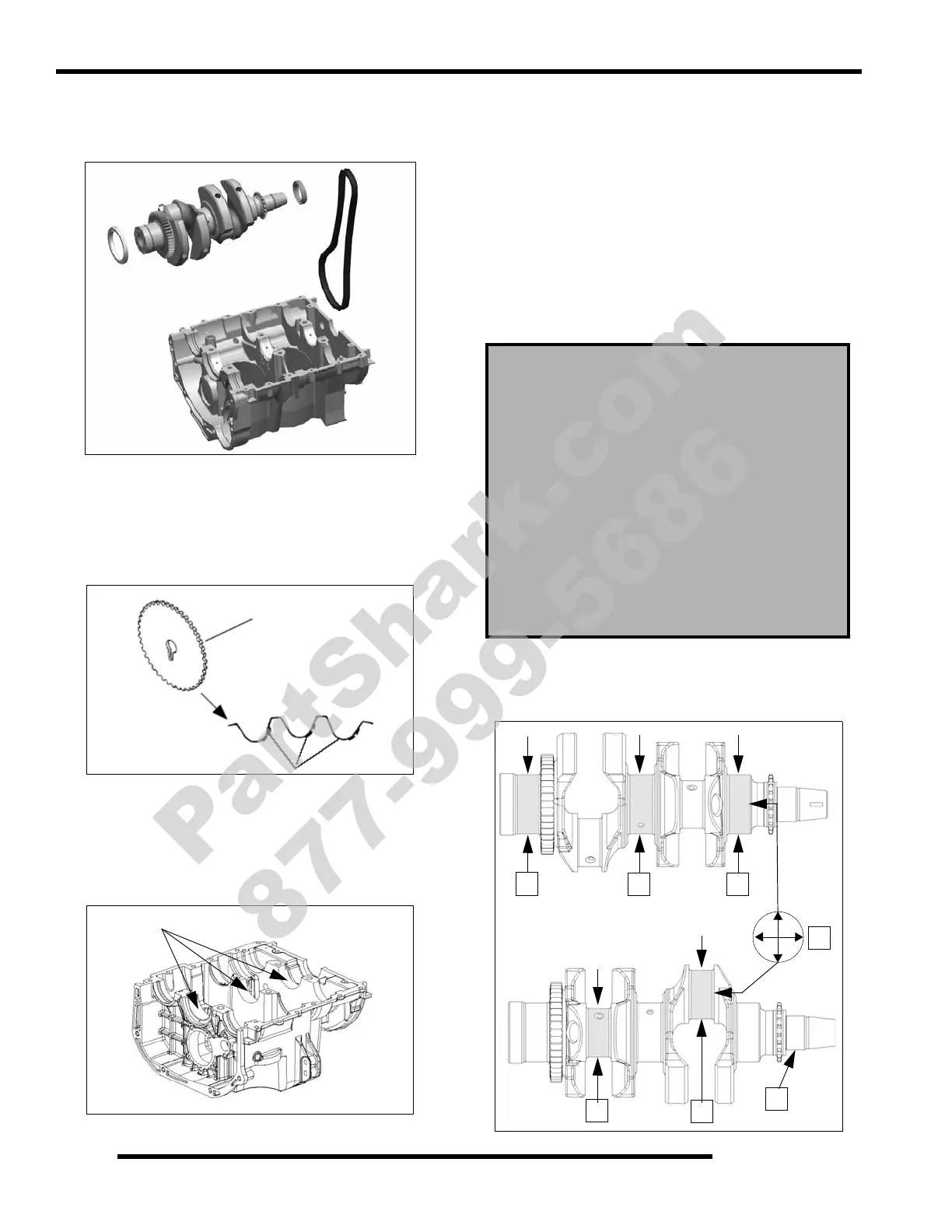

Crankshaft Inspection

1. Visually inspect surface of crankshaft main and

connecting rod journals. Replace crankshaft if any journal

is scratched or pitted.

2. Measure each main journal (A) and rod journal (B) in two

locations, 90 degrees apart. Record measurements for

bearing selection on page 5.48. Calculate the difference

between the two measurements for each journal to

determine concentricity (C). Replace crankshaft if any

journal is worn below the minimum diameter specification

or if journal out-of-round exceeds maximum specification.

3. Support crankshaft on V-blocks or on-centers in a

crankshaft stand or lathe. Measure crankshaft runout (E)

and replace if runout exceeds maximum listed above.

A - Crankshaft Main Journal Diameter:

2.1642 - 2.1650 (54.970 - 54.990 mm)

C - Crankshaft Main Journal Concentricity:

< 0.00027" (0.007 mm) Out Of Round

B - Connecting Rod Journal Diameter:

1.7718 - 1.7726 " (45.005 - 45.025 mm)

C - Connecting Rod Journal Concentricity:

< 0.00027" (0.007 mm) Out Of Round

D - Maximum Runout:

.001 " (.025 mm)

A

A A

B

B

D

C

PartShark.com

877-999-5686

Loading...

Loading...