8.40

FINAL DRIVE

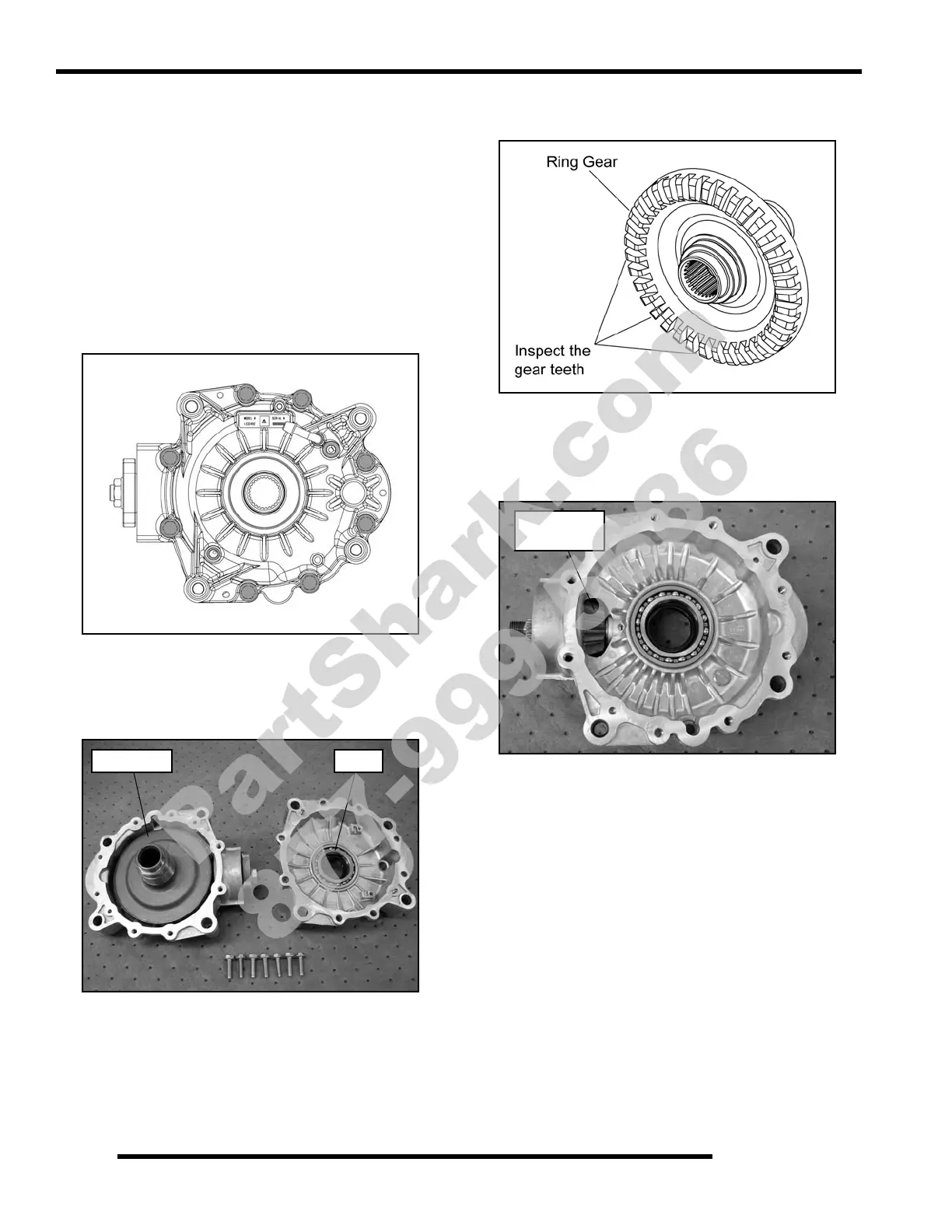

Gearcase Disassembly and Inspection

IMPORTANT: Pinion and ring gear shimming

information is NOT provided. The components are

matched at the factory which requires special OEM

tooling in order to properly assemble and shim the

gears.

In the event damage to the gears or housing requires

replacement, the entire assembly must be replaced.

1. Drain and properly dispose of used gearcase lubricant.

2. Remove the (8) screws from the rear gearcase cover.

3. Lift the gearcase cover off the main gearcase half and note

the shim between the cover and the ring gear.

4. Remove the ring gear from the main gearcase half.

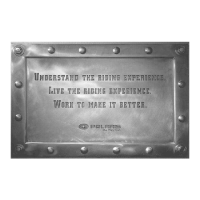

5. Inspect the ring gear teeth for chipped, worn, or broken

teeth.

6. Inspect the pinion shaft by rotating the assembly in the

gearcase housing while checking for any looseness or

roughness. Inspect the pinion gear teeth for chipped, worn,

or broken teeth.

NOTE: In the event damage to the gears or housing

requires replacement, the entire assembly must be

replaced.

7. Inspect the gearcase bearings and seals. Proceed to

“Gearcase Bearing and Seal Replacement” if components

require service.

ShimRing Gear

Inspect the

gear teeth

PartShark.com

877-999-5686

Loading...

Loading...