3.12

ELECTRONIC FUEL INJECTION

Fuel Sender Test

If the fuel gauge reading on the instrument cluster is not

working, or if the display reading differs in large comparison to

the fuel in the tank, perform a resistance test on the fuel sender.

Disconnect the fuel pump / sending unit connection and measure

the resistance between the Purple and Brown wires. If out of

specification, replace the fuel pump / tank assembly.

Fuel Pump Test

NOTE: The fuel pump / tank assembly is a non-

serviceable assembly and must be replaced if

determined to be faulty. If a fuel delivery problem is

suspected, make certain the pump is being activated

by the ECU and EFI relay, all electrical connections

are properly secured, the 20A EFI fuse is good, and a

minimum of 7.0 volts is being supplied.

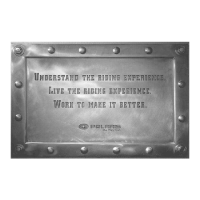

1. Couple the Fuel Pressure Gauge Adaptor (PS-48762) to

the Fuel Pressure Gauge Kit (PU-43506-A).

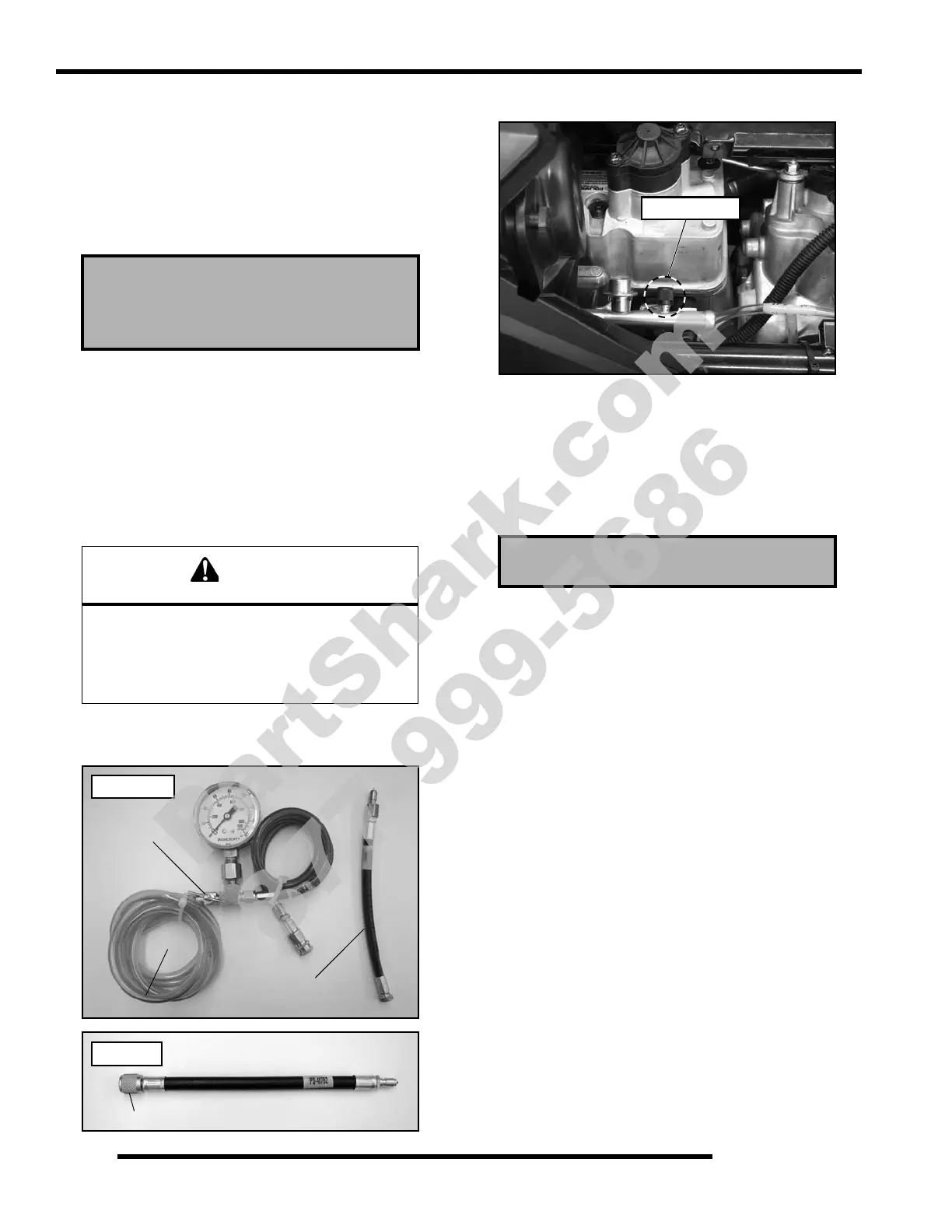

2. Locate the fuel pressure valve attached to the fuel rail.

3. Remove the black cap and attach the fuel pressure gauge

kit and adaptor to the pressure valve. Route the clear hose

into a portable gasoline container or the vehicle’s fuel tank.

4. Turn on the key switch to activate the pump and check the

system pressure on the gauge. If system pressure of 43 psi

± 3 is observed, turn the key switch “off” and depress the

valve button on the tester to relieve the system pressure.

NOTE: If the fuel pressure is out of specification,

replace the fuel pump / tank assembly.

5. If the pump did not activate (Step 4), disconnect the plug

from the fuel pump. Connect a DC voltmeter across

terminals “A” and “C” in the plug on the vehicle harness

side. Turn on the key switch and observe voltage to ensure

a minimum of 7 volts is present.

NOTE: If the voltage was below 7 VDC, test battery,

ignition switch, EFI relay and wiring harness.

6. If the reading is between 7 and 14 volts, turn key switch off

and connect an ohmmeter between the terminals “A” and

“C”' in the plug on the pump harness to check for continuity

within the fuel pump.

NOTE: If there was no continuity between the pump

terminals, replace the fuel pump / tank assembly.

7. If voltage at the plug was within the specified range, and

there was continuity across the pump terminals, reconnect

the plug to the pump, making sure you have clean

connections. Turn on the key switch and listen for the pump

to activate.

NOTE: If the pump starts, verify you have the

correct amount of fuel pressure.

8. If the pump still does not operate, check ECU operation by

plugging in a known-good ECU of the same model.

NOTE: If the pump still does not operate, replace the

fuel pump / tank assembly.

Fuel Sender Resistance Specifications:

Full: 6 Ω

Empty: 90 Ω

CAUTION

Fuel is extremely flammable and may cause

severe burns, injury, or death.

Do not use any device that produces a flame or

electrical devices that may spark around

fuel or fuel vapors.

Relief Valve

Adaptor shown is

included with kit.

PU-43506-A

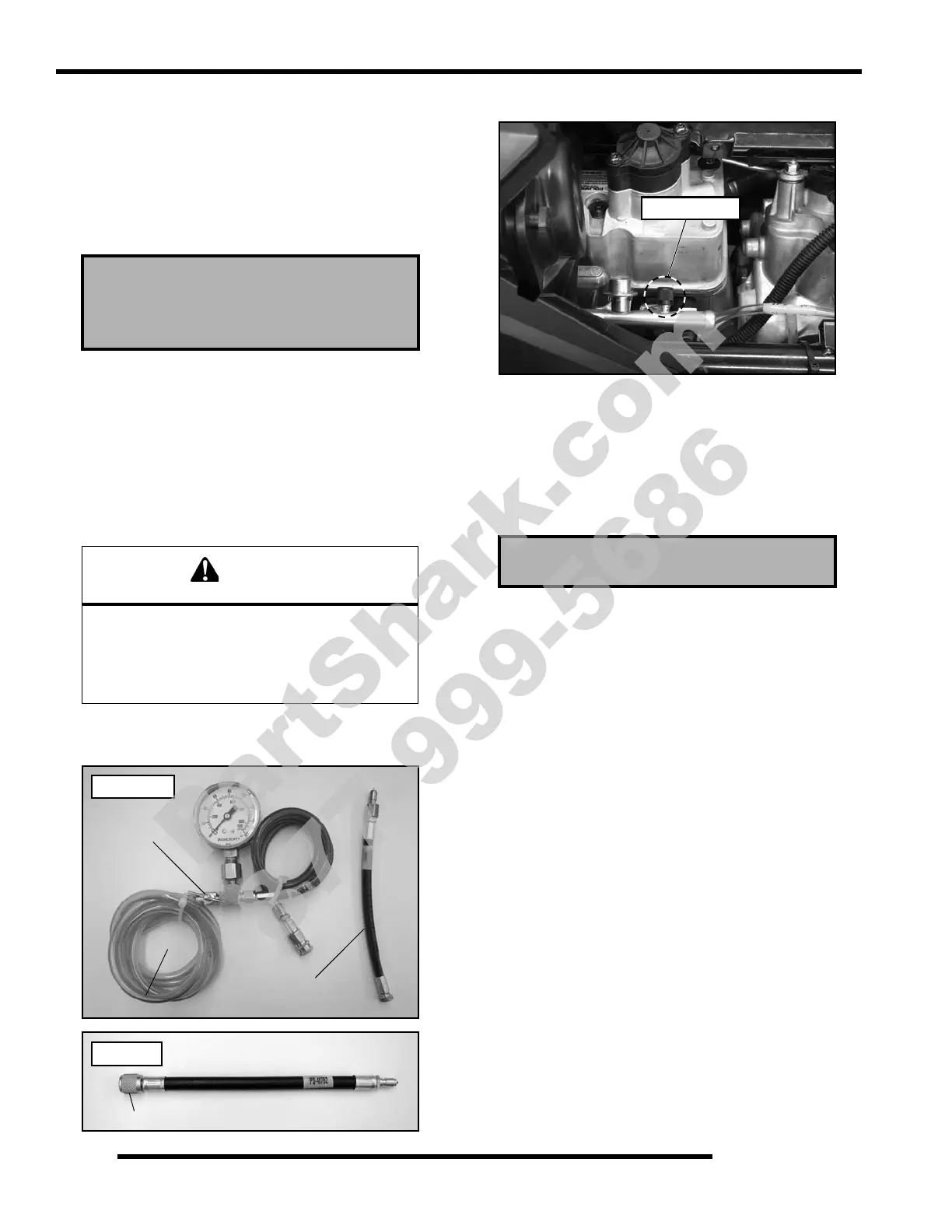

PS-48762

7/16-20 Schrader

Fuel Pump Pressure: 43 psi ± 3

Pressure Valve

PartShark.com

877-999-5686

Loading...

Loading...