14 Rockwell Automation Publication 750-AT006D-EN-P - January 2022

Chapter 1 Background

because they generate more phase lag than notch filters. As a result, only apply low pass filters if you run out of notch filters, and only

reserve them for resonances with the highest resonant frequencies.

Load Side Resonances

Even when all motor side resonances are suppressed and the motor shaft is tightly controlled using closed loop feedback, the load end

effector can still oscillate at a few Hertz through a compliant mechanical connection or linkage to the motor. These oscillations are load side

resonances that are unobservable in the feedback signal and are not measurable by the feedback device on the motor. Load side

resonances result in end effector vibration that is common in robots, cranes, cantilevered loads, anti-sway, liquid sloshing, laser cutting, and

material handling applications.

Load side resonance suppression requires one of the following techniques, or a combination of them:

• Determine the load oscillation frequency with a stopwatch and apply a reference notch filter at that frequency. Then select a smooth

reference move profile. This technique is recommended, and is the simplest to implement.

• Select a move type in 10:931 [Ref Move Type] that generates a reference profile that will not excite the load side resonance. Choices

for move type are: LinScurve, SineSquared, Poly5, and Cubic.

• Determine the load oscillation frequency with a stopwatch and generate a smooth reference CAM profile that does not contain any

load oscillation frequency content.

• Place a feedback device on the load and set the drive to load side feedback mode

See Position Loop

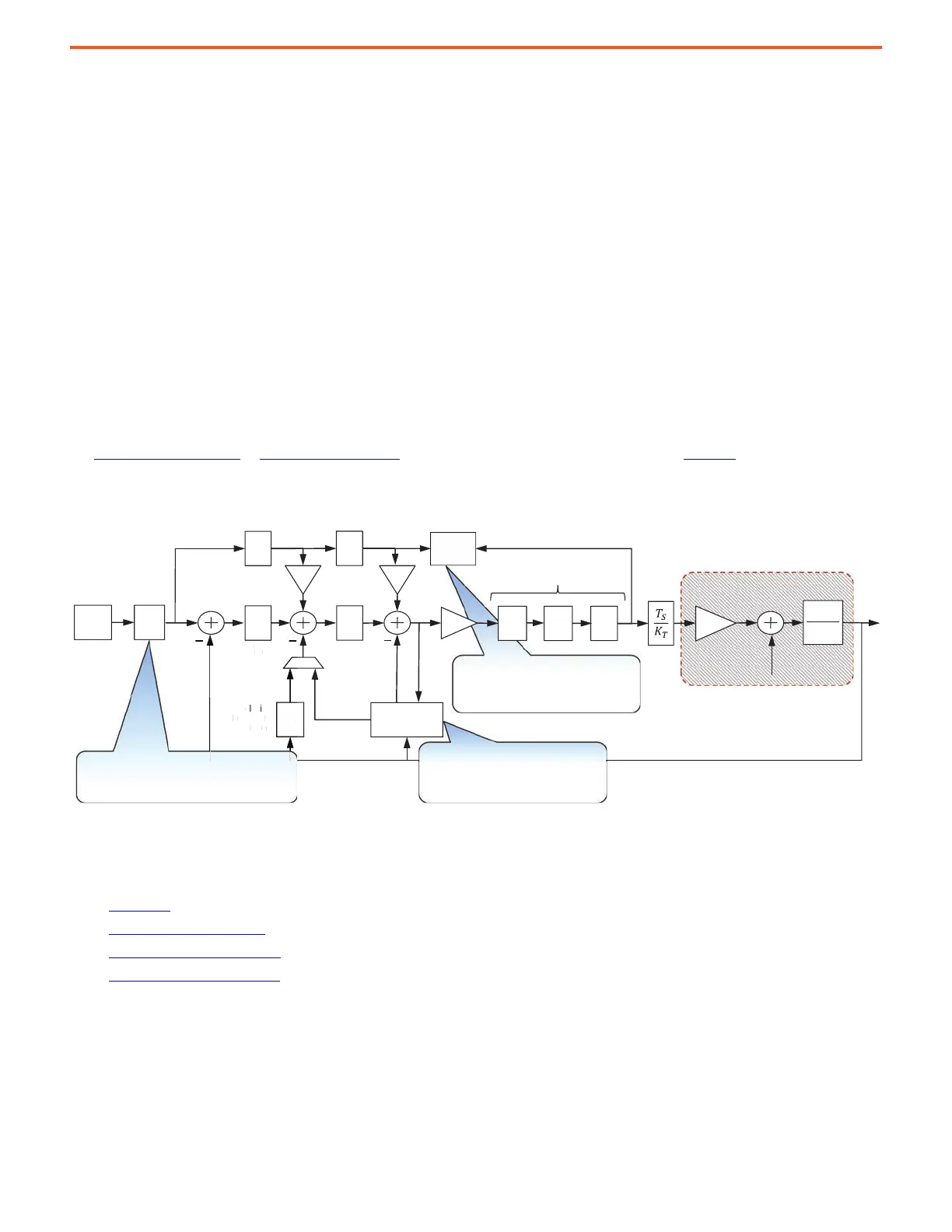

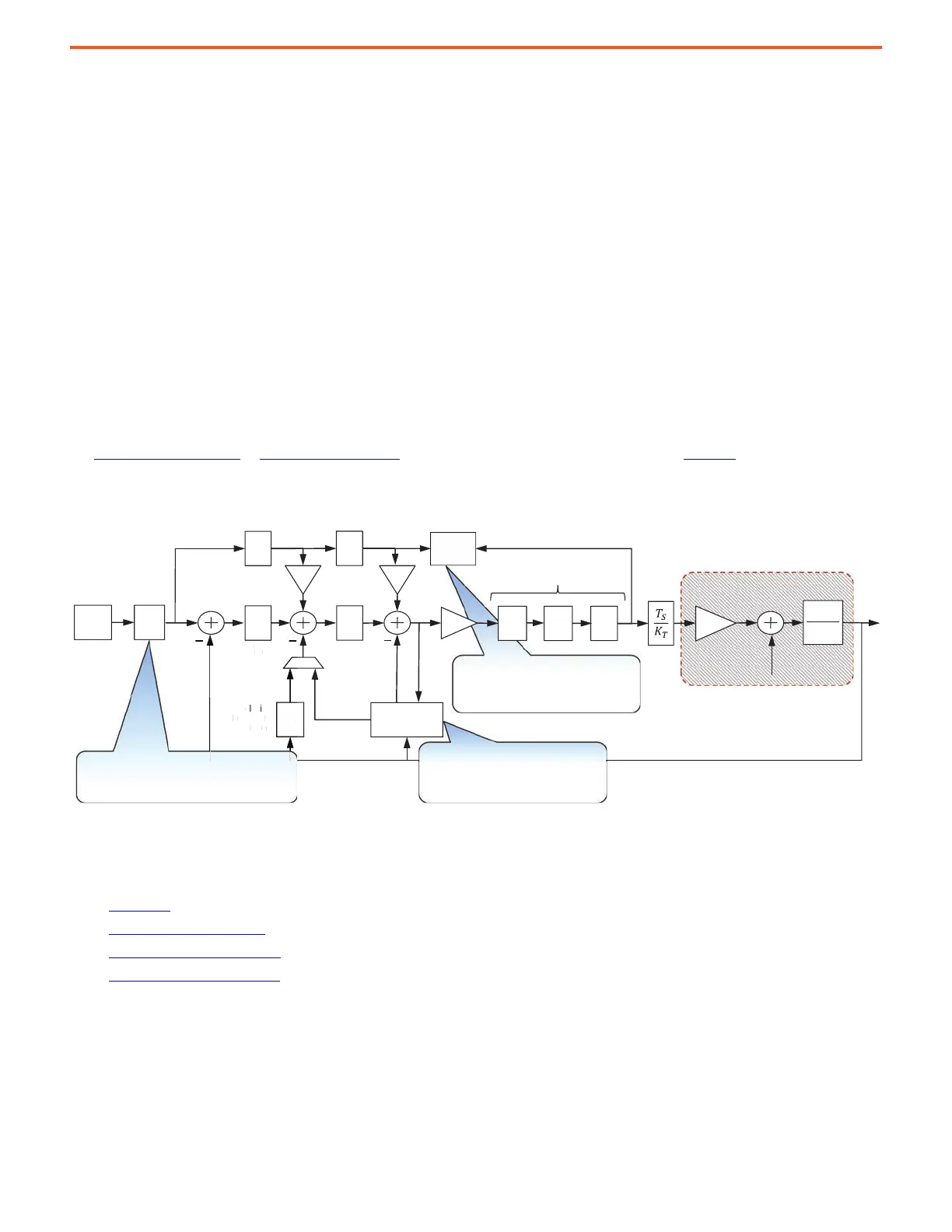

on page 20 or Velocity Loop on page 21 for more information on reference notch filters. Figure 10 shows which features

are used to control various resonances.

Figure 10 - Controlling Resonance

Performance

The following sections describe the metrics that are used to adjust performance during tuning:

• Bandwidth

• Damping Factor on page 16

• System Bandwidth on page 16

• System C/U Select on page 18

Adaptive Tuning compensates

• MF Resonances

• HF Resonances

2

1

sJ

T

PI

s

PI

s

Fs

K

T

P

REG

V

REG

Velocity

Feedback

Filter

Position

Feedback

Velocity

Estimate

Feed

Forwards

Kvff Kaff

Position

Command

LP

LL

N

Torque Loop Filters

Load Torque

Load

Observer

K

J

Torque

Estimate

Adaptive

Tuning

RN

System Under Control

P

REF

Load Observer compensates

• Inertia

• LF Resonances

e

Reference Notch Filters compensate

• Load Resonances

Loading...

Loading...