16 Rockwell Automation Publication 750-AT006D-EN-P - January 2022

Chapter 1 Background

Damping Factor

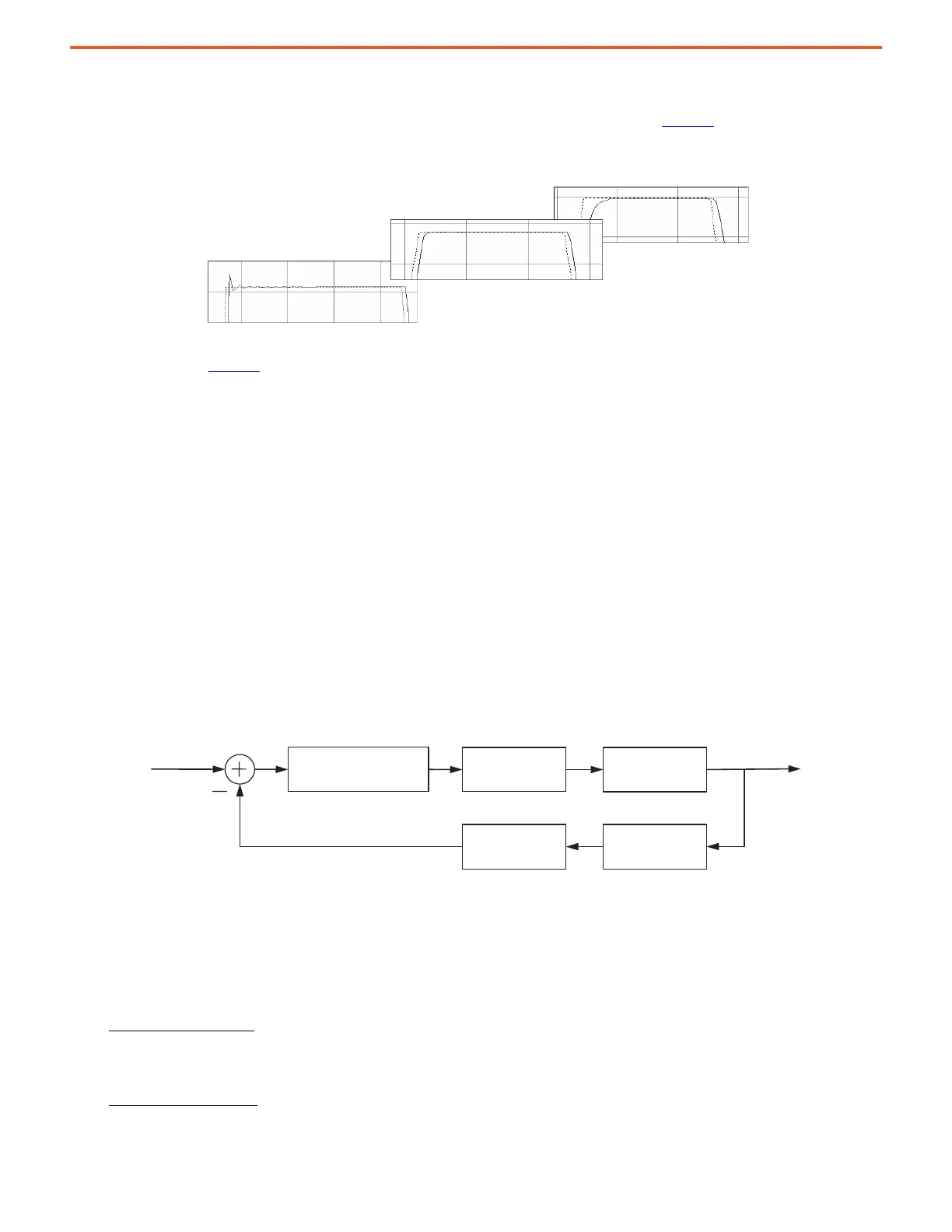

The damping factor is commonly referred to as zeta (Z). It affects the rise time for a given bandwidth. Figure 13 shows how the damping

factor affects actual response (solid) compared to its reference move profile (dashed). Here, feed forward gains are disabled.

Figure 13 - How Damping Affects Transient Response

The examples shown in Figure 13

are discussed:

• A damping factor of Z < 1 produces high responsiveness, which is characterized by a faster rise time with overshoot.

• A damping factor of Z = 1 produces medium responsiveness, which is characterized by the fastest possible rise time without

overshoot. This value is the default and recommended setting.

• A damping factor of Z > 1 produces low responsiveness, which is characterized by a slower response without overshoot, similar to

decreasing the bandwidth.

10:907 [System Damping] adjusts the position, velocity, and torque loop spacing of the calculated control loop gains and load observer gains.

It also adjusts the integrator spacing of calculated gain parameters to generate the required responsiveness.

A lower damping factor decreases the spacing between the position, velocity, and torque loop bandwidths. It also increases integrator gains.

This value generates under-damped responses in the position and velocity response. A higher damping factor generates over-damped

responses.

System Bandwidth

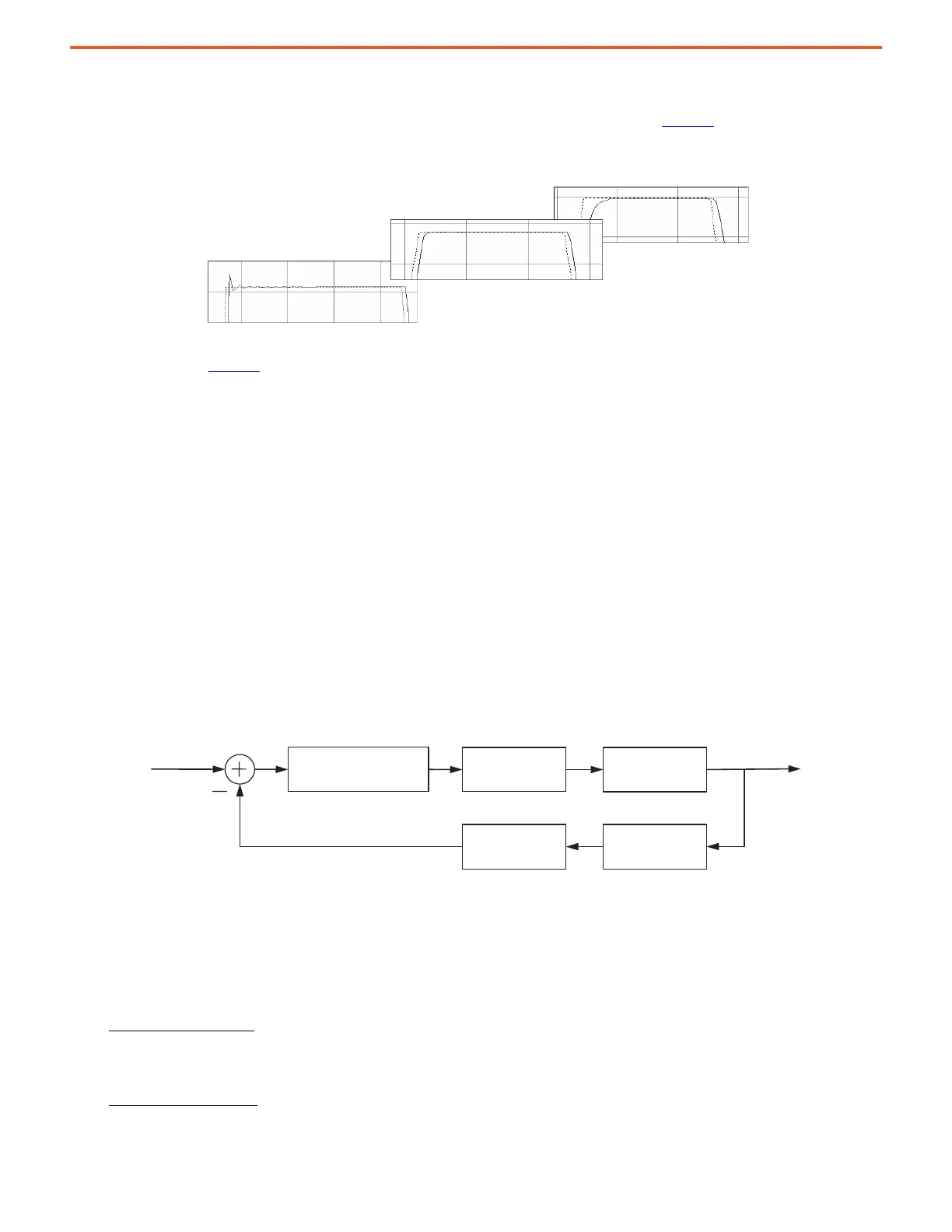

System bandwidth is calculated from an internal quantity that is called the drive model time constant (DMTC). The DMTC is the sum of all

delays around the torque loop for a given drive and motor combination.

Figure 14 - Delays Associated with DMTC

The following parameters are used to calculate the DMTC.

• 10:445 [VCL CReg BW] – This parameter is the current regulator bandwidth

• 10:407 [Motor Poles] – This parameter is the number of motor poles (p). It is calculated as follows

p = round (120 x [Motor NP Hertz] / [Motor NP RPM])

• Primary Encoder Resolution – This parameter is the total resolution in edge counts per revolution (EPR) specified by parameters on

the primary feedback option card.

Low-Resolution Example:

Resolution = 1024 pulses per revolution * 4 quadrature edge counts per pulse = 4096 EPR (12-bit). The low-

resolution PPR comes directly from a parameter on the option card. When both A and B channels are selected for an incremental

encoder, the edge count multiplier is 4. This value is the typical and default setting. When only channel A is selected, then the edge

count multiplier is 2.

High-Resolution Example:

Resolution = 1024 pulses per revolution * 1024 edge counts per pulse = 1,048,576 EPR (20-bit). For high-

resolution devices, the overall resolution choices are 20-bit default or an optional 24-bit when the corresponding configuration bit is

selected.

Under Damped

High: Z < 1

Over Damped

Low: Z > 1

Critically Damped

Medium: Z = 1

PI Regulator

Computational Delay

Command

Current Loop

Time Constant

Motor Electrical

Time Constant

Feedback

Sample Delay

Feedback Filter

Time Constant

Actual

Loading...

Loading...