Rockwell Automation Publication 750-AT006D-EN-P - January 2022 87

Chapter 6 Active Front End Tuning

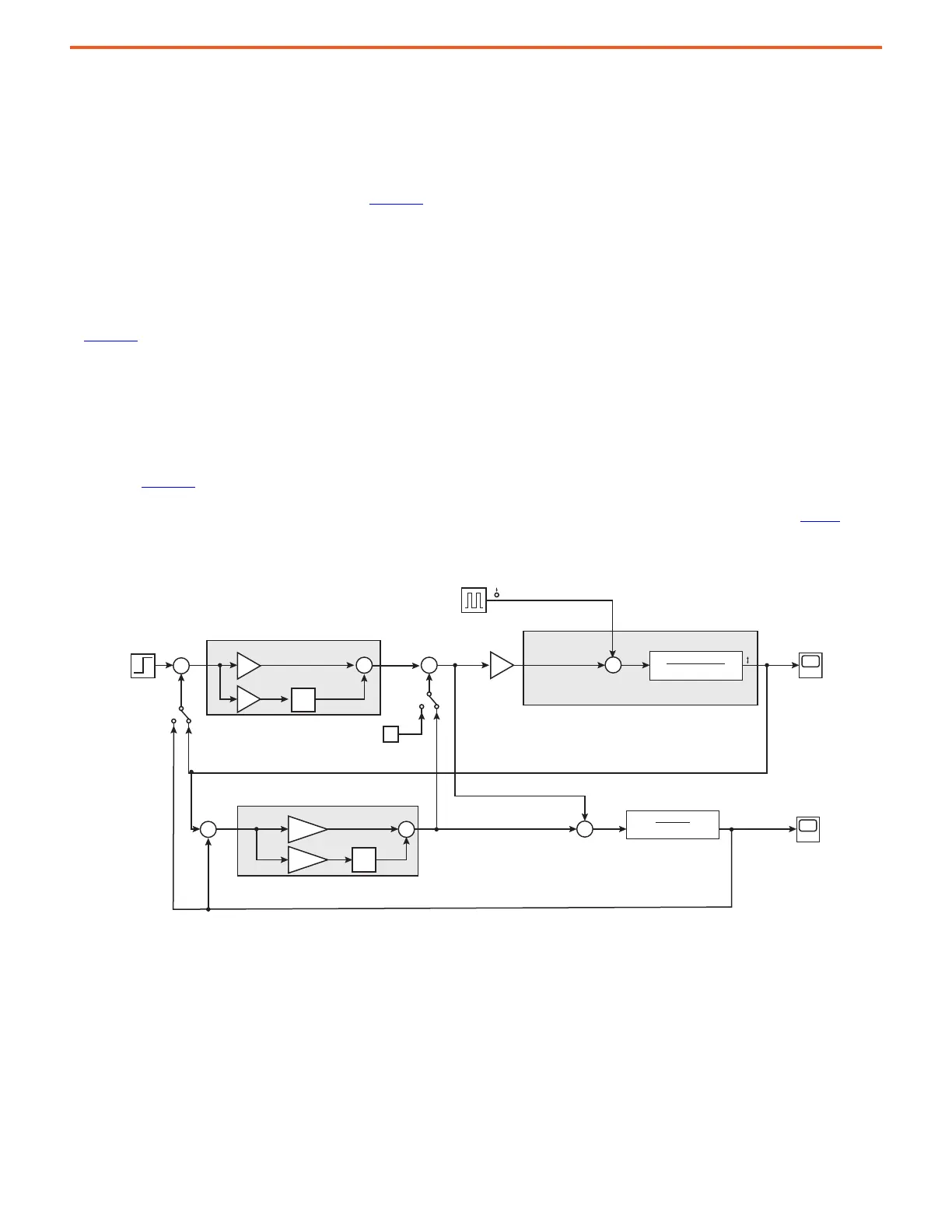

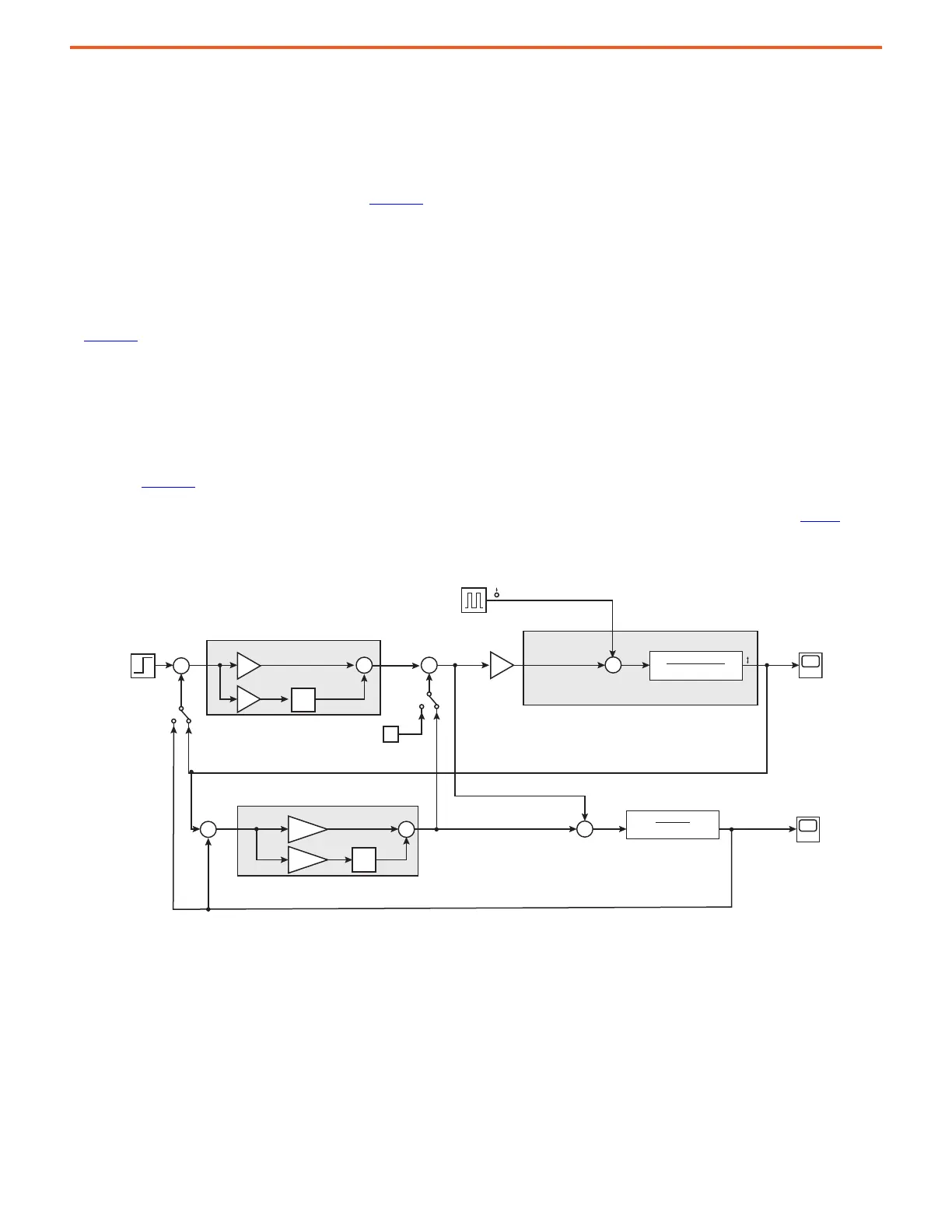

DC Bus Observer

Basic concepts

In 755TM bus supply applications, the measured instantaneous power on the inverter side is not available. Therefore, the DC Bus observer is

designed to estimate the load on the DC side of the power converter in real time. This estimated load is then fed back to cancel the effect of

the actual load, as shown in the simplified model in Figure 73

. This forces the plant to behave consistently, which makes it easier to achieve

and control higher performance levels. The DC Bus observer relies on processing the error difference between the measured DC bus voltage

and an estimated DC bus voltage through a PI controller. The deviation between the measured and the estimated DC bus values are mainly

due to external disturbances, such as load changes, or parameter variations, such as a fluctuation in DC bus capacitance. This occurs in

common DC bus applications where loads are being frequently connected to and disconnected from the DC bus. The system can be

configured to use either the measured DC bus voltage or the DC bus voltage estimated by the observer as the feedback signal for the voltage

control loop. The estimated DC bus current is displayed in real time for the purpose of load monitoring; see 13:325 [BusObs Curr Est].

In Figure 73

, notice that the current regulator B

W

is usually set 5 to 10 times higher than the voltage regulator B

W

. Consequently, the dynamics

of the current regulator can be ignored, and it can be represented by a unity again. The total capacitance of the system (C) is defined as the

summation of the internal capacitance (C

int

) and the external capacitance (C

ext

). The bus observer can automatically compensate for external

capacitance that is less than four times the internal capacitance of the drive

.

The DC bus observer uses an ideal model of the system with a feedback loop to estimate the disturbance, which represents any difference

between the real model and the actual system, including C

ext

, load changes, parameter variation, and so on.

As shown in Figure 73

, the algorithm consists of two interactive control loops; a standard DC bus voltage regulator, which is mainly

responsible for reference tracking, and the DC bus observer, which is mainly responsible for disturbance rejection. The system can be

configured to use the measured DC bus voltage or the estimated DC bus as a feedback signal for the voltage control loop. See Tuning

for

more information.

Figure 73 - Simplified Functional Block Diagram for DC Bus Observer

+

-

+

-

+

+

+

-

+

+

+

+

+

+

0

V DC

REF

I

q

VbusObsReg

Iq_Load_Est

VbusReg

Iq_Load

+

1

V DC

Power converter

Plant-Bus Capacitance

Inial Bus Capacitance

1

C

INT

• s

Vdc_Est

CurrentLoop

1

(C

INT

+ C

EXT

)s

1

—

s

1

—

s

K

P

K

I

K

POBS

K

IOBS

Loading...

Loading...