30 Rockwell Automation Publication 750-AT006D-EN-P - January 2022

Chapter 2 Product Features

Benefits

You can use the load observer with out-of-box control loop gains, where the load is unknown or compliant and thus 10:901 [Load Ratio] = 0,

or with autotuned control loop gains, where 10:901 [Load Ratio] > 0 is a known positive value or calculated by performing an autotune

procedure.

When the load observer is enabled with the recommended out-of-box control loop gains, load observer does the following:

• Automatically compensates for changing inertia, compliance, and low frequency resonances

• Provides relatively high-performance control without tuning

• There is no longer the need for a tuning expert

• No periodic retuning to account for machine wear over time

• Reduces commissioning time, especially for high drive count

When the load observer is enabled with autotuned control loop gains, load observer does the following:

• Automatically compensates for load disturbances

• Minimizes tracking errors, machine vibration, and power consumption

• Allows bandwidth and line speeds to be increased

• Provides tighter control of moving parts, which reduces wear and saves material costs

How It Works

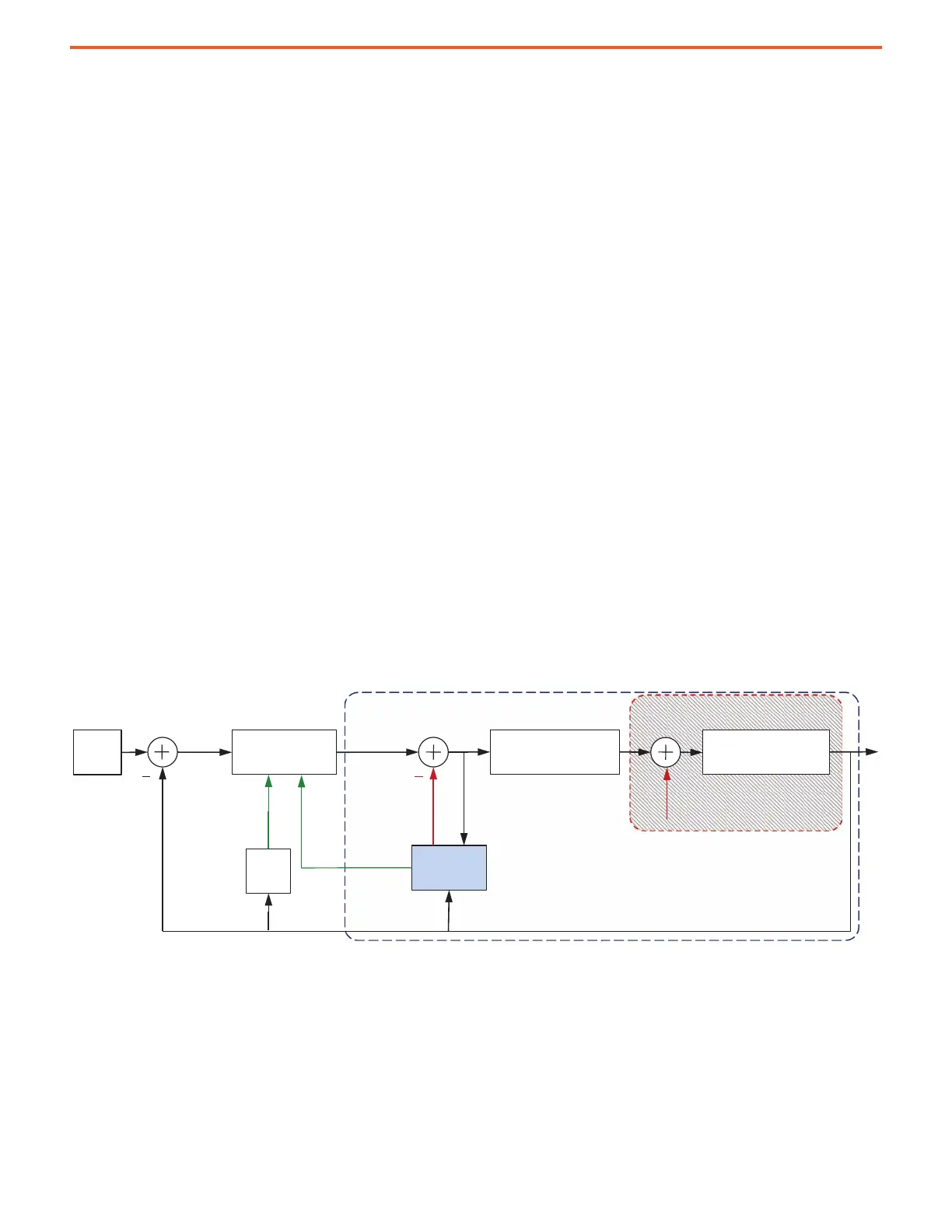

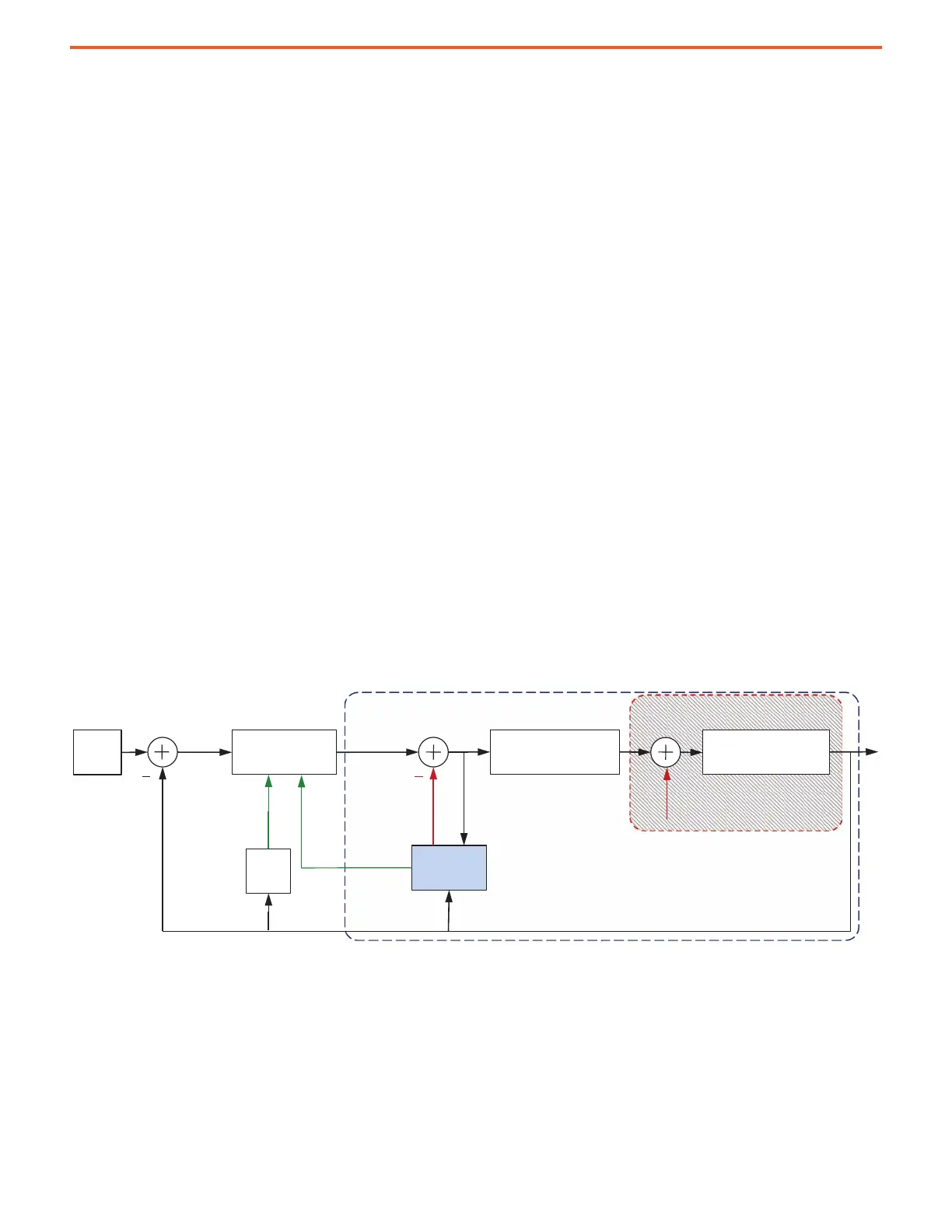

Load observer acts on the acceleration signal within the control loops and monitors the Acceleration Reference and Position Feedback

signals. Load observer uses an internal plant model (P) of an ideal motor and generates a load Torque Estimate signal that represents any

deviation in response between the actual loaded motor and the ideal model. This deviation represents the reaction torque that is placed on

the motor shaft by a mechanical load. The load torque is estimated in real-time and compensated by closed loop operation. This technique

provides system response that is similar to the response of a mechanically disconnected motor.

In the drive, the load Torque Estimate is applied through an Acceleration Estimate that is subtracted from the Acceleration Reference signal,

which is then converted to a torque signal by multiplying by the Torque Scaler.

Figure 28 - Load Observer Block Diagram

As a result, the control loops can be tuned as if controlling a disconnected motor.

The load observer also generates a Velocity Estimate signal that can be applied to the velocity loop. The Velocity Estimate has less delay than

the Velocity Feedback signal that comes from the velocity feedback FIR and low pass filters. It also helps to reduce high frequency output

noise that is caused by the load observer aggressively acting on the Acceleration Reference signal. Together, load observer with velocity

estimate provides the best overall performance for position control applications.

System Under Control

Load

Observer

Power Converter

Control Loops

Fs

Unloaded Motor

Acceleration

Reference

Torque

Estimate

Velocity

Estimate

Position

Feedback

Torque Load

P

REF

Velocity

Feedback

Filter

Unloaded Motor Response

Loading...

Loading...