Engineering manual - SAB 193-233-283 S A-frame (including ATEX)

42/175

008831 en 2022.02

Technical description

4.6 Variable speed drive (VSD)

The compressor can be VSD driven as long as the rpm limits are not exceeded. For standard

and total unloading compressors, UniSAB III controls the VSD combined with the mechanical

capacity control in the most efficient way considering both energy consumption and wear.

It should be noted that compressors running variable speed (VSD) are at higher risk of facing

vibrational problems than similar fixed-speed applications. Johnson Controls Denmark and the

Sabroe Factory have gained comprehensive experience in VSD, and we are integrating this

knowledge into both the mechanical design and the control systems of our products. For this

reason, we cannot accept liability for any damage related to vibrations or variable speed drive

on non-factory-built equipment. This includes both mechanical and electrical equipment,

meaning that VSD equipment must be purchased as complete factory-built and tested pack-

ages to ensure optimum reliability and to attain full factory warranty coverage. It should be

noted that vibrations may appear as structural vibrations in for instance frames, piping and in-

strumentation, or as torsional vibrations in rotating equipment: compressor shaft, coupling and

motor rotor.

4.7 Compressor lubrication system

The lubrication system on a screw compressor unit performs several functions:

• It provides lubrication to bearings and seal.

• It provides a cushion between the rotors to minimise noise and vibrations.

• It helps keep the compressor cool and prevents overheating.

• It provides an oil supply to hydraulically actuate the slide valve and slide stop.

• It provides oil pressure to the balance pistons to increase bearing life.

• It provides an oil seal between the rotors to prevent rotor contact or gas bypassing.

The compressor unit may be equipped with either a “no pump” or a “demand pump” lubrication

system. Additionally, either system may contain:

• Dual oil filters and liquid injection.

• Water-cooled or thermosyphon oil cooler for compressor oil cooling.

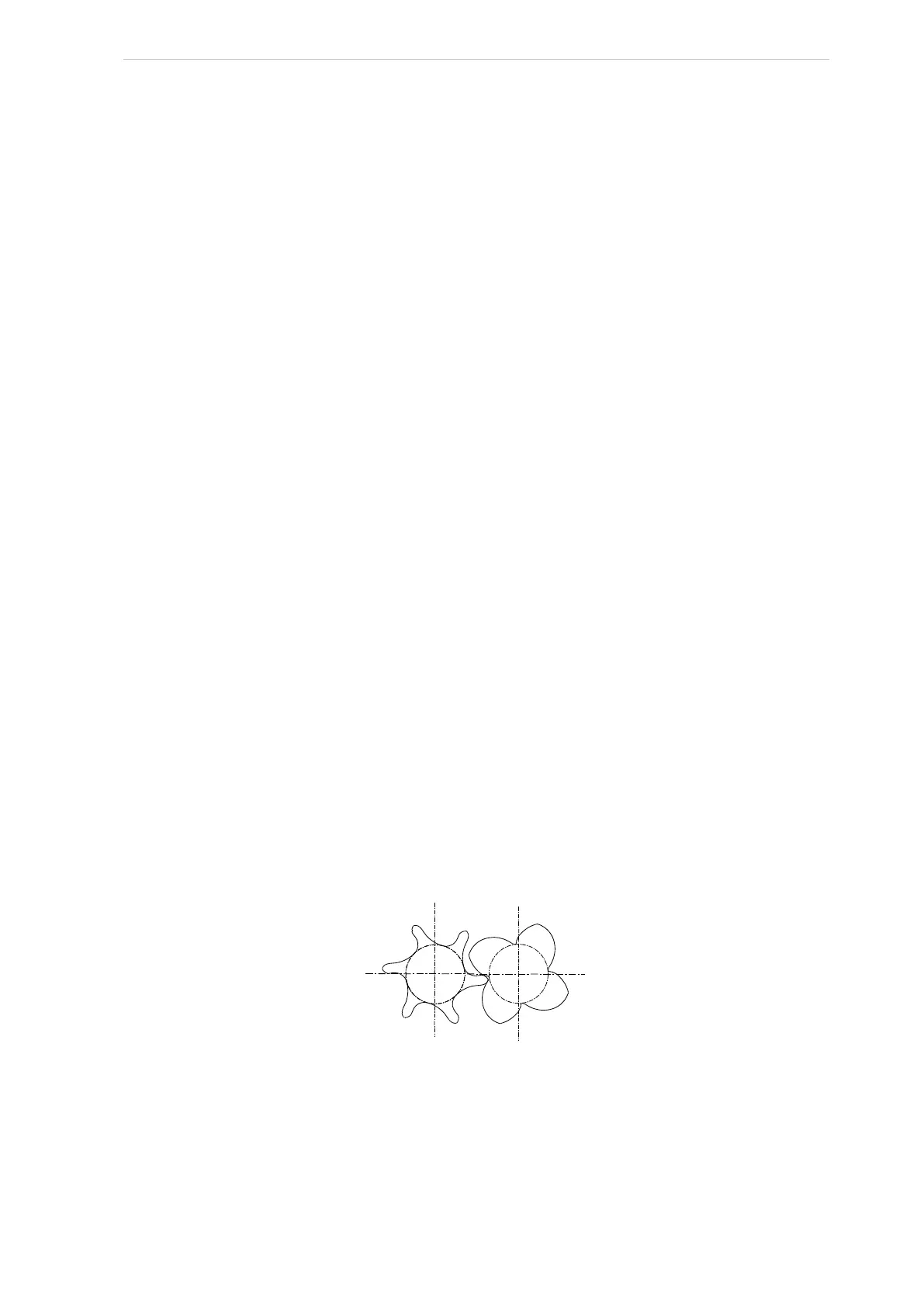

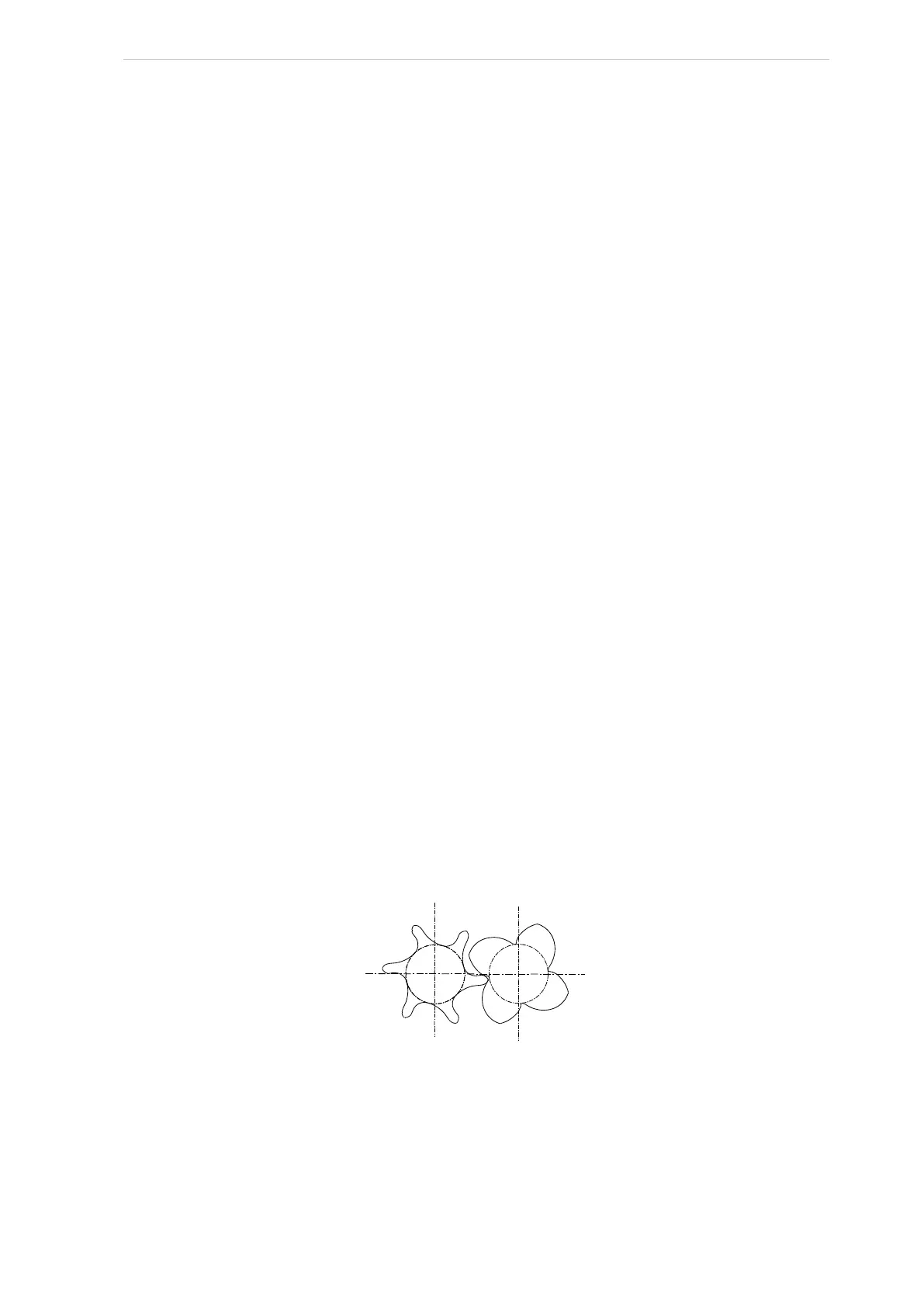

The rotors are constructed with an asymmetrical profile. The male rotor has four lobes, and the

female rotor has six, see Fig. 18.

Fig. 18: Female/male rotor

A shaft seal is mounted at the shaft end (driving shaft) of the male rotor. The shaft seal ensures

complete tightness between the compressor housing and the compressor shaft, thus prevent-

ing atmospheric air from entering the compressor.

Loading...

Loading...